Combination mirror collision and reliability comprehensive test platform

A comprehensive test bench and comprehensive test technology, applied in the field of combined mirror collision and reliability comprehensive test platform, can solve the problems of cumbersome, not too laborious, human head injury, etc., and achieve high precision, convenient installation and positioning, and ingenious structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments according to the present invention will be described in detail below with reference to the accompanying drawings.

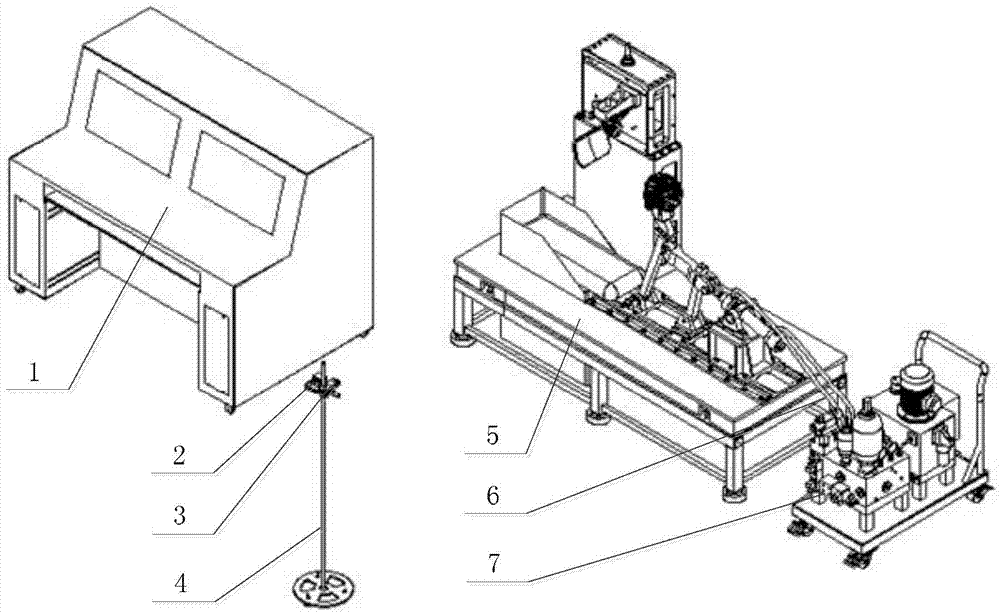

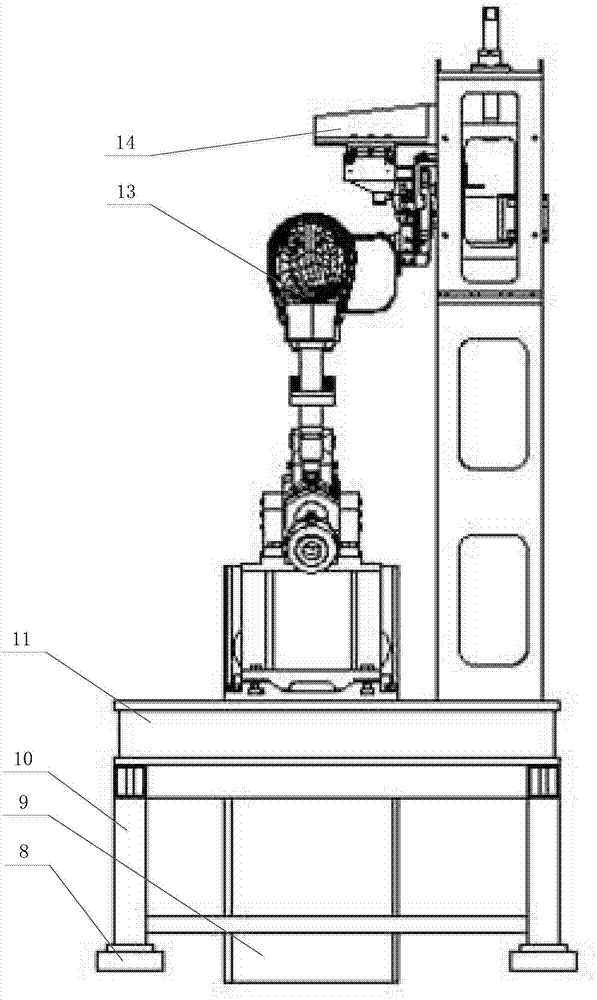

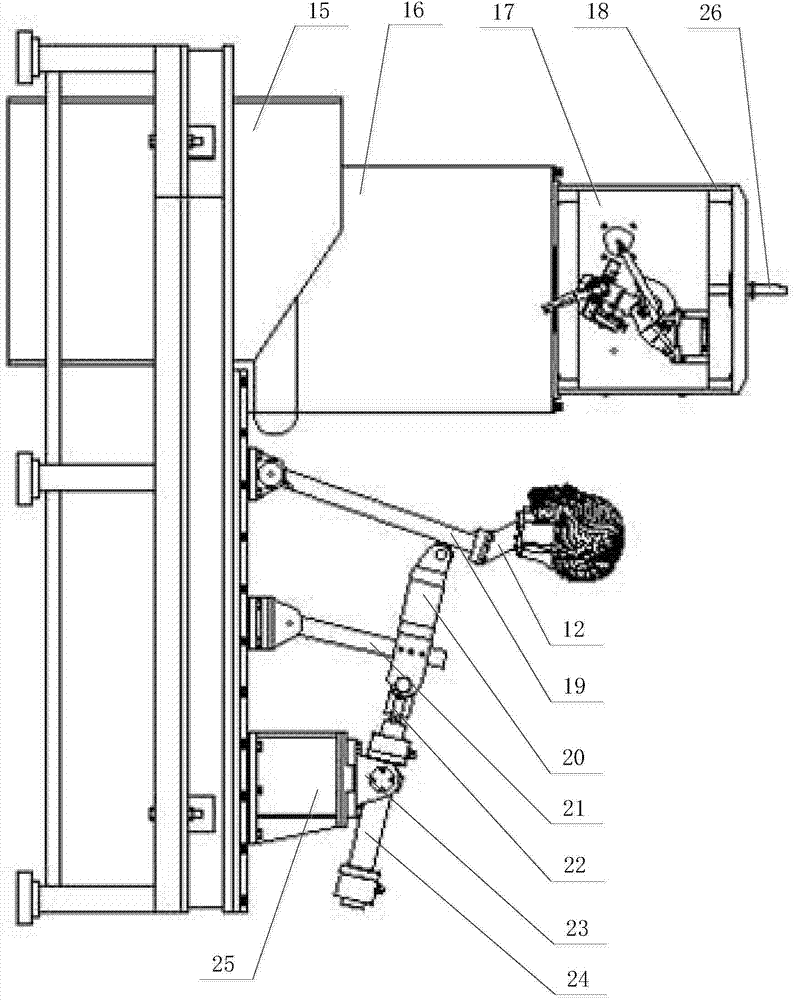

[0042] As shown in the accompanying drawings, a combined mirror collision and reliability comprehensive test platform includes: a comprehensive test bench 5, functional modules such as an integrated combined mirror retractable mechanism, an operating handle simulation mechanism, and a head collision simulation device. The mechanism converts the swing of the combined mirror into the continuous rotation of the drive module, which can record the number of times of retraction and retraction and the mechanical changes in the retraction process, and truly simulate the driver's collision process, and record the kinematics and dynamic parameters of the entire process, which is the next step for reliability. , injury degree and system ergonomics research to lay the experimental foundation; hydraulic system 7, drive the head model to collide with the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com