Substrate etching method

A substrate and etching gas technology, applied in the field of microelectronics, can solve problems such as the process cannot be carried out normally, the etching is interrupted, and the key dimension of the bottom of the sidewall shrinks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

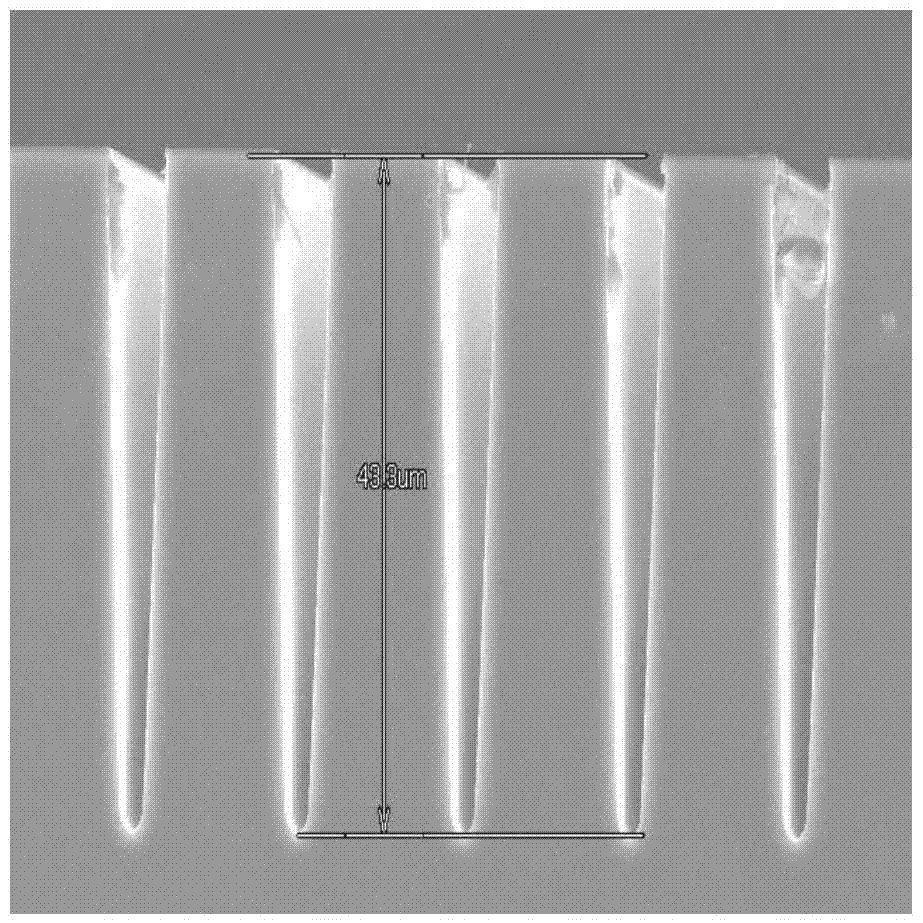

[0034] In order for those skilled in the art to better understand the technical solution of the present invention, the substrate etching method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

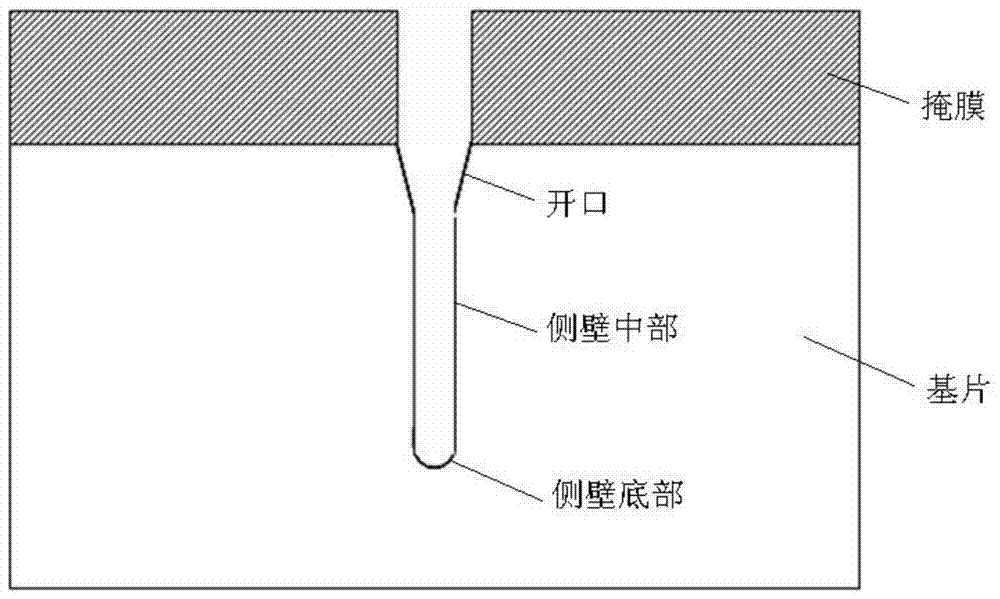

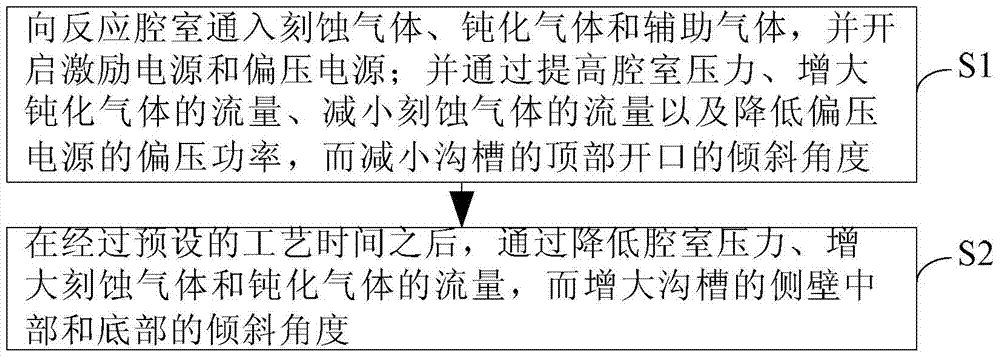

[0035] image 3 A flow chart of the substrate etching method provided by the present invention. see figure 1 , the method includes the following steps:

[0036] S1, feed etching gas, passivation gas (also known as protective gas) and auxiliary gas into the reaction chamber, and turn on the excitation power supply (such as radio frequency power supply), and the excitation power supply applies excitation power to the reaction chamber to make the reaction chamber The etching gas is excited to form plasma; the bias power supply is turned on, and the bias power supply applies bias power to the substrate, so that the plasma etches the substrate until a predetermined etching depth is etched on the substrate. Moreover, in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com