Circuit board and implementation method for interlayer interconnection structure thereof and processing method for circuit board

A technology of interlayer interconnection and implementation method, which is applied in the direction of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of high cost, poor reliability, low efficiency, etc., achieve high reliability, improve reliability, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

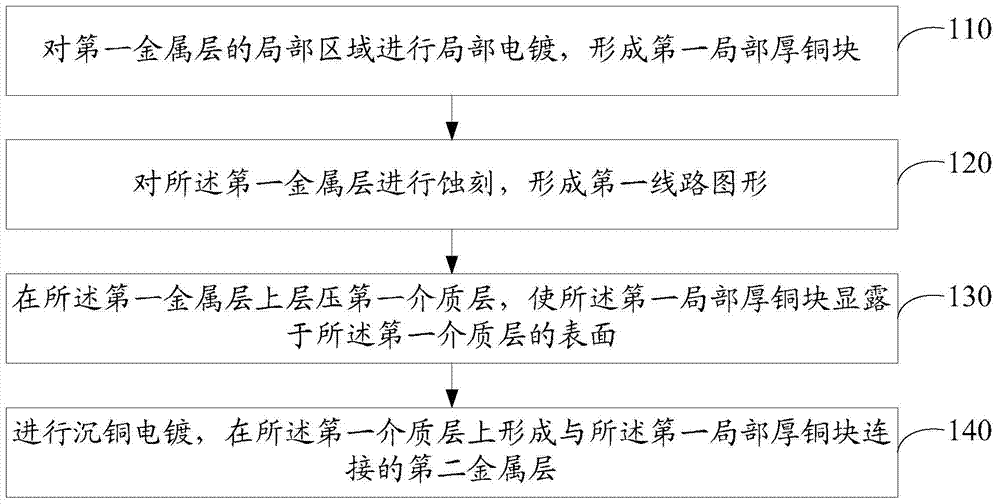

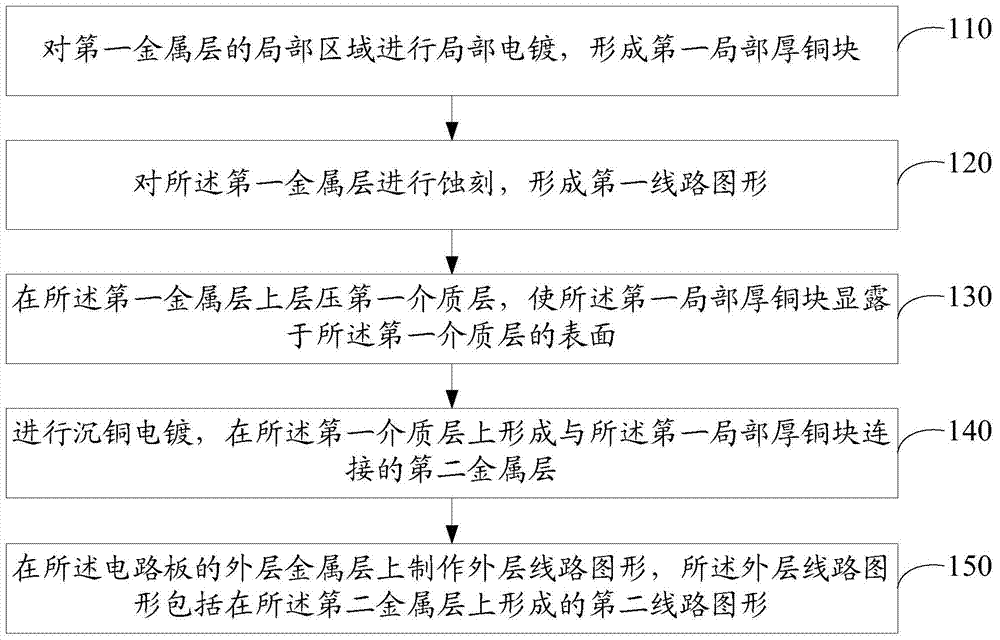

[0046] Please refer to Figure 1a , an embodiment of the present invention provides a method for realizing an interconnection structure between layers of a circuit board, which may include:

[0047] 110. Perform local electroplating on a local area of the first metal layer to form a first interlayer interconnection block.

[0048] The circuit board as the processing object initially includes at least the first metal layer. In this step, local electroplating is performed on the local area of the first metal layer that needs to be interconnected between layers, and the local area is electroplated thicker to form the The first inter-layer interconnect block required.

[0049] 120. Etch the first metal layer to form a first circuit pattern.

[0050] In this step, a conventional process, such as an inner layer pattern etching method, can be used to cover the area of the first metal layer that needs to form a circuit pattern with a resist film, and then perform etching to rem...

Embodiment 2

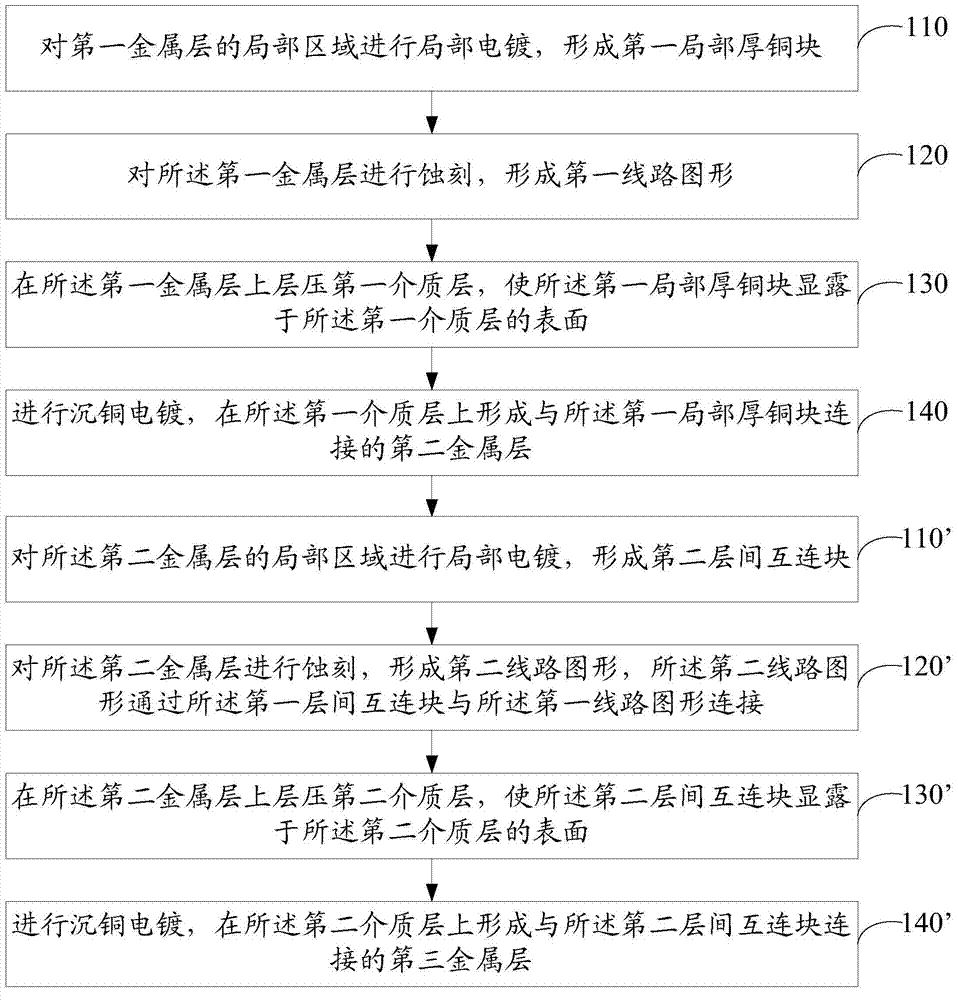

[0080] Please refer to figure 2 , an embodiment of the present invention provides a method for realizing an interconnection structure between layers of a circuit board, which may include:

[0081] 210. Perform local electroplating on a local area of the first metal layer to form a first interlayer interconnection block.

[0082] The method of the embodiment of the present invention can start processing based on the inner layer board, and the said inner layer board includes at least one zeroth dielectric layer and at least one metal layer. In this embodiment, the inner layer board is double-sided copper-clad board as an example for illustration, as image 3 As shown, the inner board includes a first metal layer 21 on the first surface, a zeroth metal layer 20 on the second surface, and a zeroth metal layer between the zeroth metal layer 20 and the first metal layer 21. Dielectric layer 19. In other embodiments, at least one inner circuit layer and at least two zeroth diel...

Embodiment 3

[0120] Please refer to Figure 4d and 4e , an embodiment of the present invention provides a circuit board with an interlayer interconnection structure, the circuit board may include:

[0121] The first circuit layer 210, the first dielectric layer 18a disposed on the first circuit layer 210, and the second circuit layer 220 formed on the first dielectric layer 18a; wherein, the first circuit layer 210 includes a first interlayer interconnection block 31, and the first interlayer interconnection block 31 is connected to the second circuit layer 220 through the first dielectric layer 18a.

[0122] In some embodiments of the present invention, the circuit board may further include:

[0123] The second dielectric layer 18b disposed on the second circuit layer 220, and the third circuit layer 230 formed on the second dielectric layer 18b; wherein, the second circuit layer 220 includes a second interlayer interconnect The connection block 32, the second interlayer interconnectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com