Piezoelectric stack

一种压电层、叠体的技术,应用在涂层、电路、压电器件/电致伸缩器件等方向,达到抑制衰减、电荷保持量高、电荷保持性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

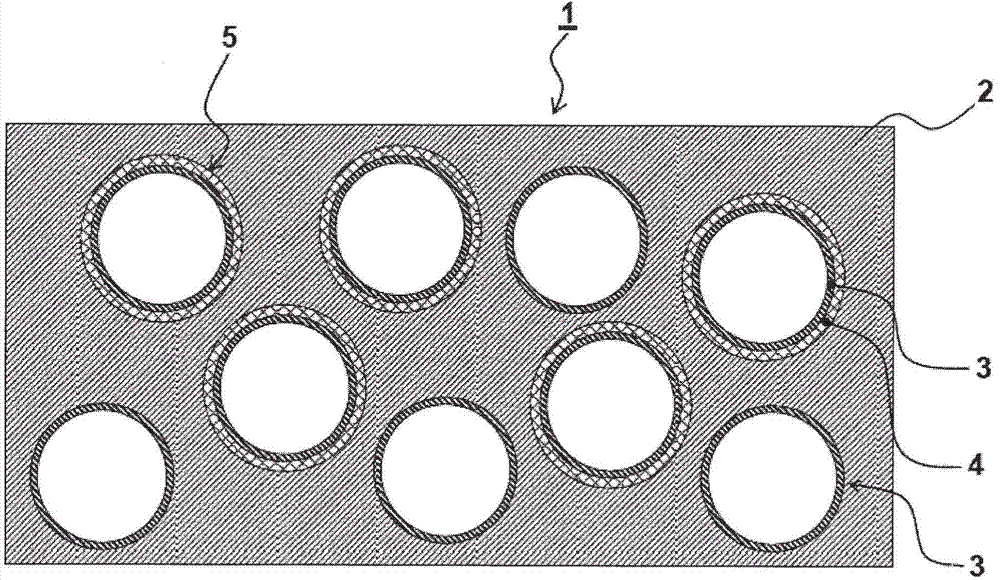

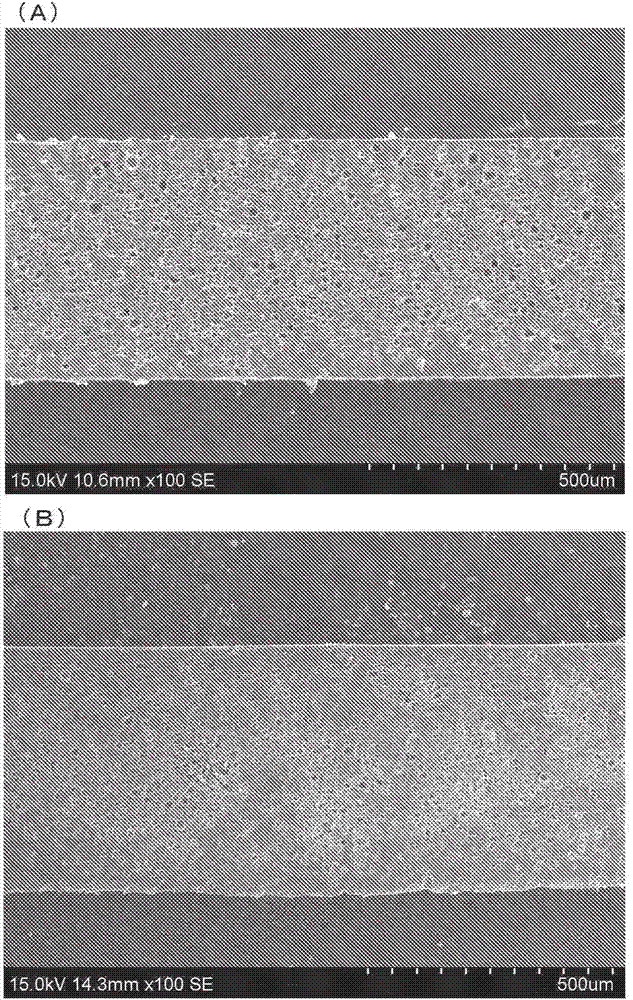

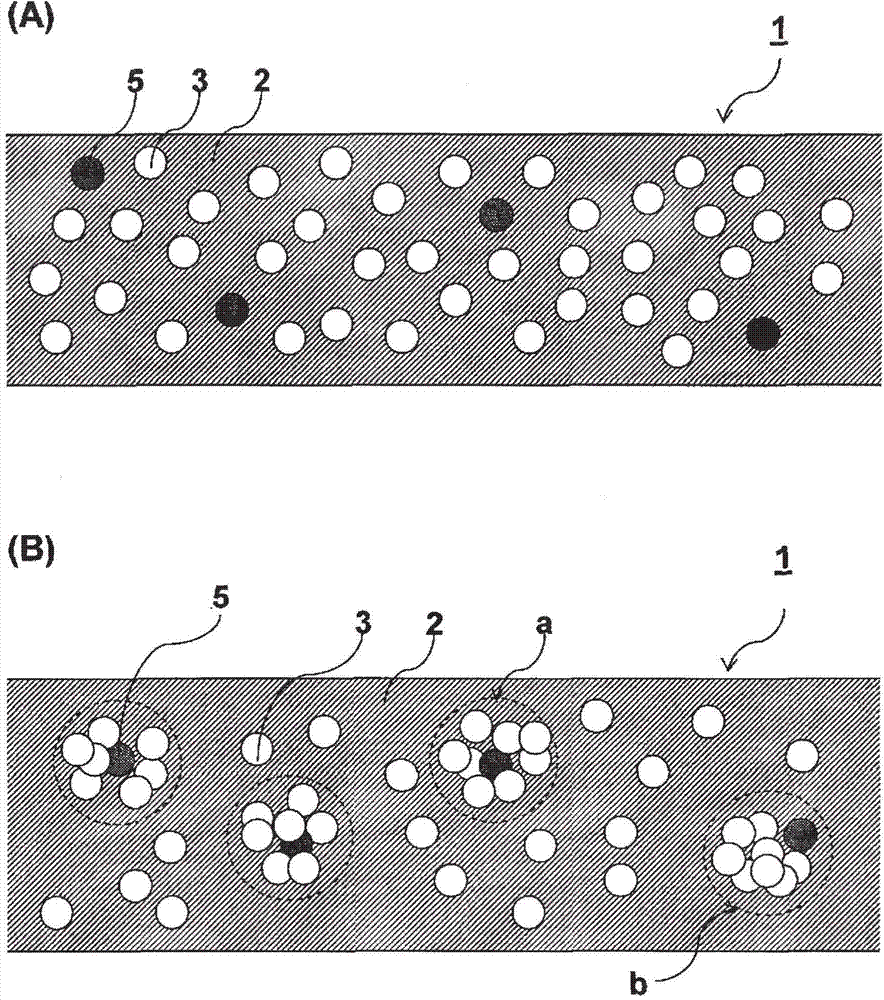

[0311] [Example 1] A laminate in which a surface coating layer is provided on both the front and back sides of a porous resin sheet (single-side covered piezoelectric laminate)

[0312]

[0313] 100g of fluororesin (FEP, NP101 manufactured by Daikin Industries) (thermal decomposition start temperature: 400°C; electrical conductivity: 1.0×10 -16 S / cm; MFR: 24g / 10 minutes (ASTMD2116); Melting point: 255°C (ASTMD2116); Apparent density 1.21g / ml (JISK6891)) is mixed with 4.3g of hollow glass beads (Potters-Ballotini company) as hollow particles System, 60P18, conductivity: 1.0×10 -14 S / cm). The hollow rate of the mixture was 10%.

[0314] The calculation of the hollow ratio is performed as follows.

[0315] Hollow rate (volume%) = ((volume A - volume B) / volume A) × 100

[0316] Volume A: Calculated volume based on material weight and material specific gravity (absolute specific gravity)

[0317] Volume B: The volume calculated based on the weight of the material and the s...

Embodiment 2

[0334] [Example 2] A laminate in which a surface coating layer is provided on both surfaces of a porous resin sheet (a double-sided covered piezoelectric laminate)

[0335]

[0336] 18.6 g of hollow glass beads (iM30K, manufactured by Sumitomo 3M Corporation) were mixed with 100 g of fluororesin (FEP, NP-101 manufactured by Daikin Industries, Ltd.). The hollow rate of the mixture was 30%. The hollow ratio was measured by the same method as in Example 1. The resulting mixture was molded in the same manner as in Example 1 to obtain a 3 cm x 3 cm x 0.2 mm sheet (porous resin sheet).

[0337]

[0338] A fluororesin sheet (PFA film "AF0025" manufactured by Daikin Industries, Ltd., 25 μm, volume resistivity 1.0 × 10 18 Ω·cm) were press-bonded by hot stamping at 300° C. at a pressure of 2 MPa for 180 seconds to form a laminate (piezoelectric laminate). The modulus of elasticity was measured in the same manner as in Example 1, and the piezoelectric coefficient was measured in t...

Embodiment 3

[0343] [Example 3] A laminate in which a surface covering layer is provided on both sides of a porous resin sheet formed of a PTFE nonwoven fabric (a double-sided PTFE nonwoven fabric piezoelectric laminate)

[0344]

[0345] According to the electrospinning method described in Japanese Patent Publication No. 2012-515850, polytetrafluoroethylene (PTFE) fibers are gathered into a sheet to produce a PTFE nonwoven fabric with a thickness of 60 μm (porosity 80%, elastic modulus Weight 6MPa) formed porous resin sheet.

[0346]

[0347] The porosity is measured based on the following method.

[0348] The table is calculated using the weight of a test piece obtained by cutting the porous resin sheet into a 4 cm square (4 cm in the vertical direction and 4 cm in the horizontal direction) and the thickness measured by the microcal (LITEMATIC VL-50, manufactured by Mitsutoyo Co., Ltd.). The apparent density is used to calculate the porosity by the following mathematical formula.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com