Gas push type self-mixing combined purifying tank

A purifying tank and push-type technology, which is used in gas production bioreactors, bioreactor/fermenter combinations, mixers, etc. The effect of reducing production cost, facilitating application and promotion, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

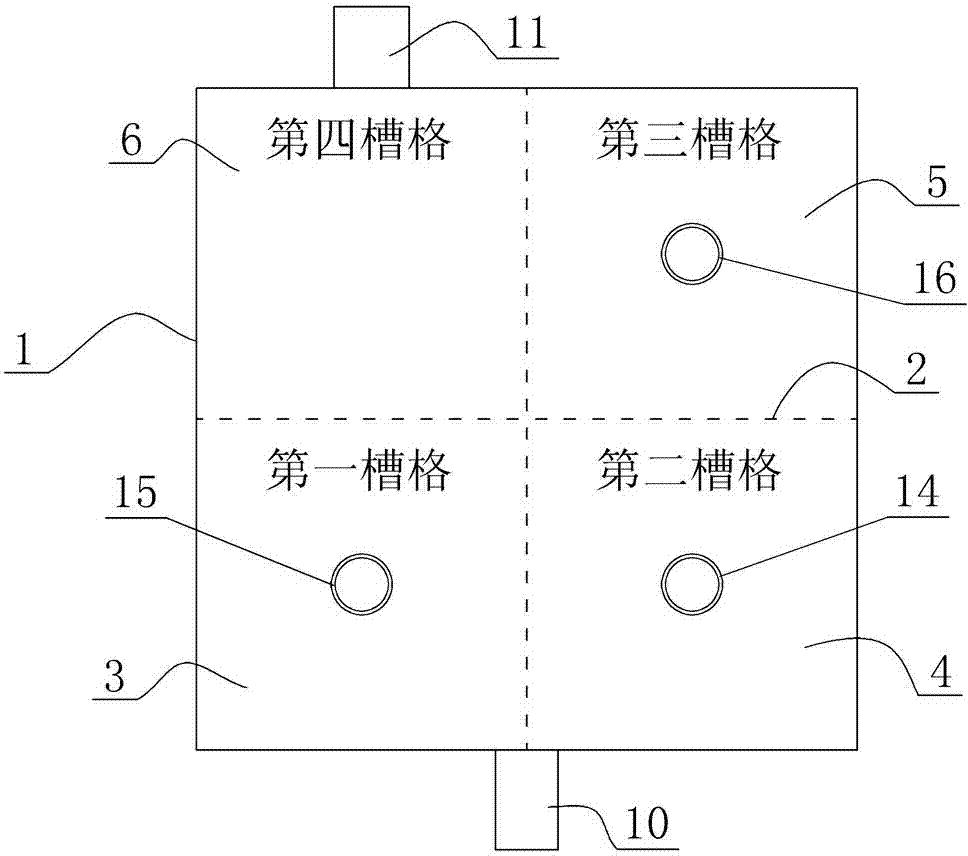

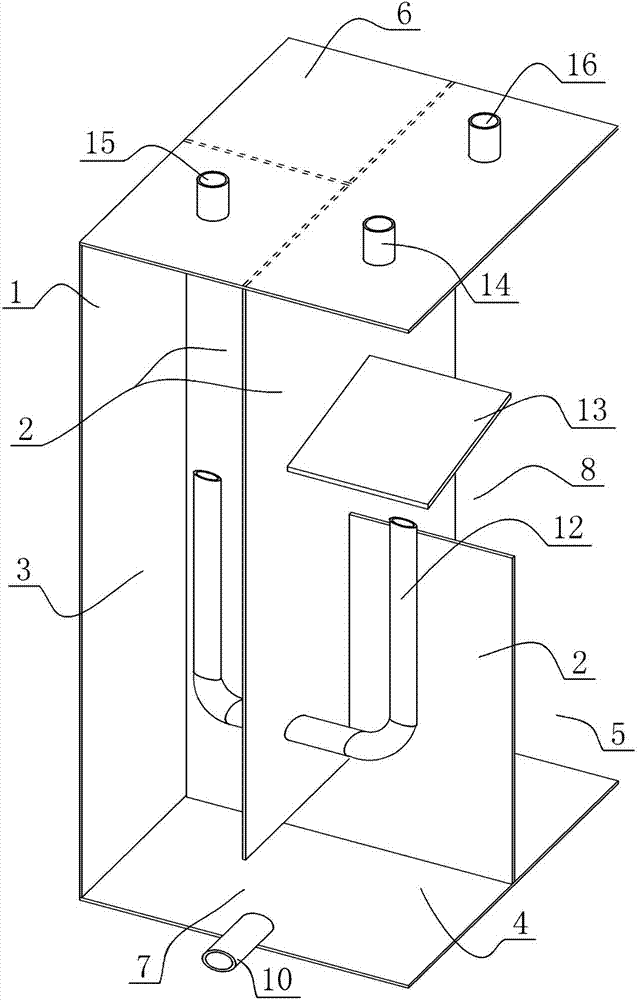

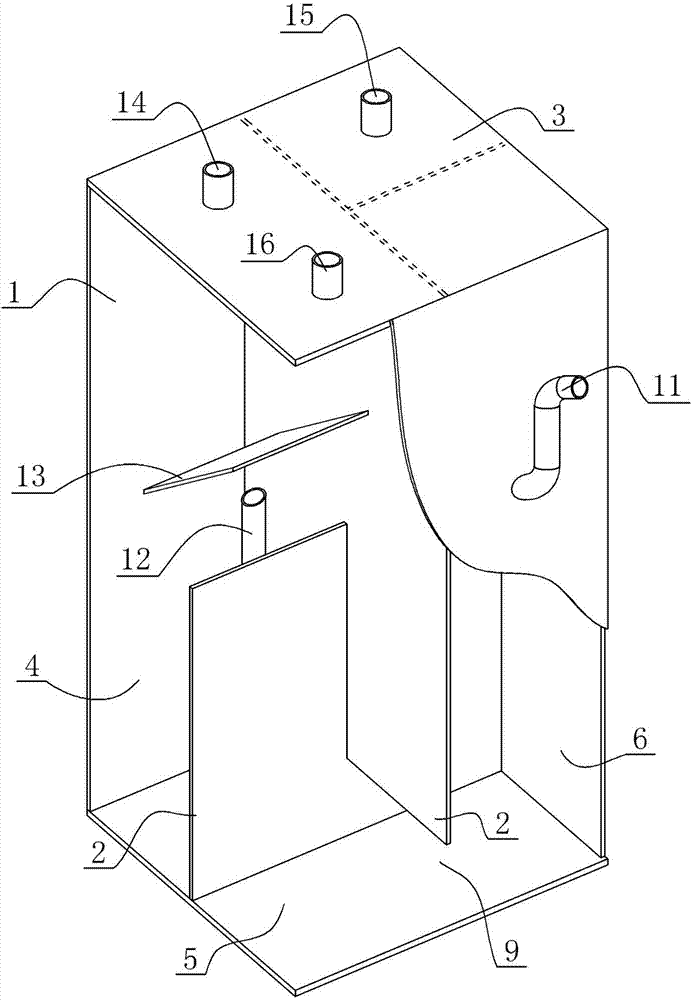

[0018] Such as figure 1 As shown, the principle diagram of the gas-propelled self-stirring combined purification tank of the present invention is provided, figure 2 with image 3 Its three-dimensional structure diagram is given, and the combined purification tank shown includes an outer wall 1, a partition plate 2, a feed pipe 10, a discharge pipe 11, a U-shaped pipe 12, an air guide plate 13, a gas outlet 14, and a first gas circulation Port 15 and second gas circulation port 16; the interior of the outer wall 1 shown is a cavity, and the partition plate 2 divides the cavity in the outer wall 1 evenly into a first cell 3, a second cell 4, and a third cell 5 and the fourth slot 6. The lower end of the partition between the first cell 3 and the second cell 4 is provided with a first opening 7, while the U-shaped pipe 12 is arranged on the partition b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com