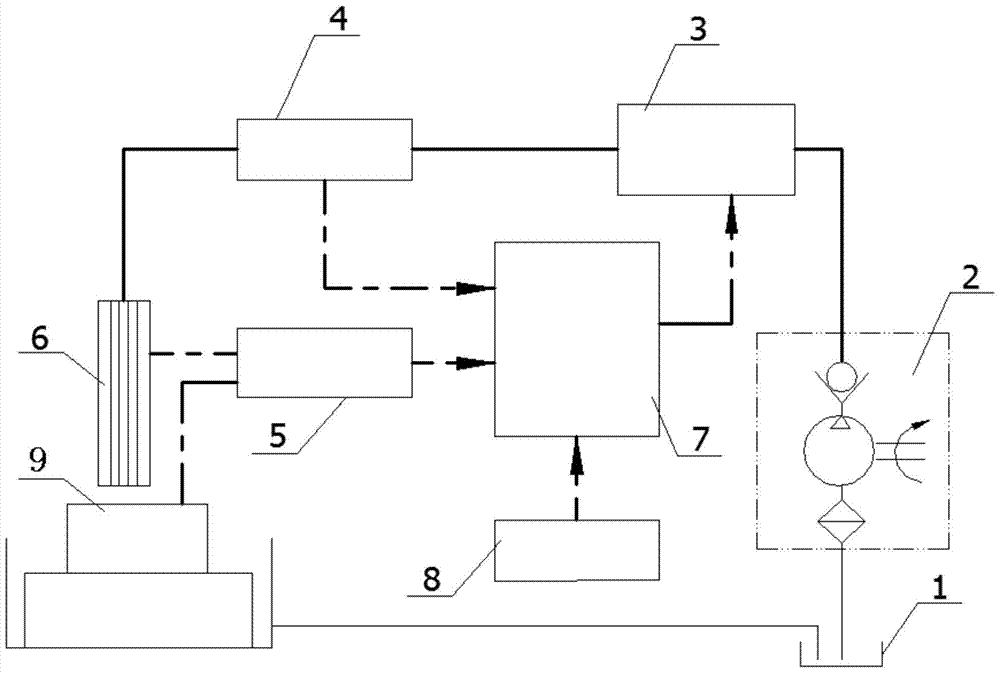

Adaptive liquid flushing system for high-speed arc discharge machining

An arc discharge and self-adaptive technology, applied in electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of inability to self-adaptively adjust fluid medium parameters, complex control parameter setting process, and huge proportional control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment illustrates the implementation method of the self-adaptive flushing system in the process of high-speed arc discharge layer milling, and the control unit 7 adopts the artificial neural network algorithm to realize self-adaptive adjustment. Firstly, the trend of the change process of each state quantity in the process of layer milling is explained: during the feeding process in which the feeding direction is parallel to the cutter axis, since the opening electrode 6 and the workpiece 9 are constantly approaching, the back pressure of the flushing pipe starts to increase at this time Large, the discharge current gradually increases and is accompanied by liquid dielectric breakdown discharge, and the open circuit voltage decreases; after the workpiece electrode is fed into the workpiece, due to various factors such as chip removal efficiency and feed rate, the discharge state changes. If it cannot be eliminated in time, the state will deteriorate, the back p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com