Full-automatic intelligent plane polishing machine

A surface grinding machine, fully automatic technology, applied to machine tools suitable for grinding workpiece planes, parts of grinding machine tools, grinding machines, etc., can solve the problems of accidental injuries caused by others, environmental pollution, noise pollution, and inability to grind various Product and other issues, to achieve the effect of improving equipment utilization, improving safety factor, and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

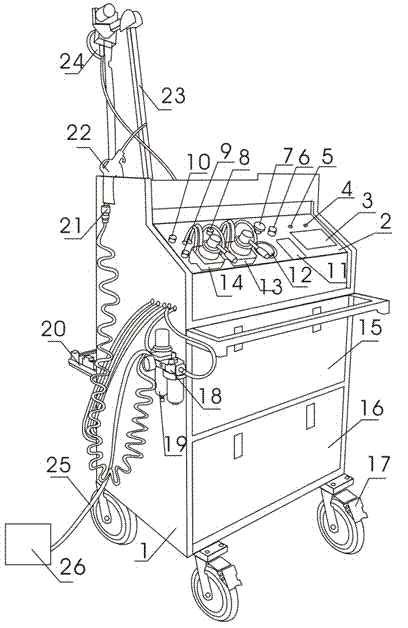

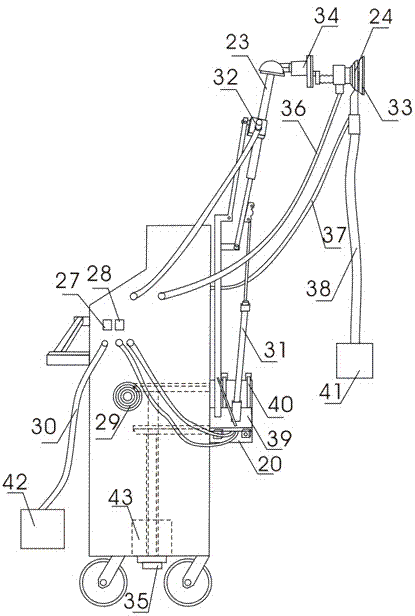

[0035] like Figure 1-2 As shown, the fully automatic intelligent plane grinding machine according to the embodiment of the present invention includes a plane grinding machine body 1, a host panel 2, a host power distribution box 15, a storage box 16, a universal self-locking wheel 17, a sliding table 20 and Pneumatic control manipulator 23, the upper part of the plane grinder body 1 is provided with a host panel 2, the front end of the plane grinder body 1 is respectively provided with a host power distribution box 15 and a storage box 16, and the side of the plane grinder body 1 is respectively provided with an oil-water separator 18. Rotary grinding button 27, mechanical arm telescopic button 28, fan 29, power bus 30, among which the oil-water separator 18 is provided with a lubricating oil filling pipe 19 at the bottom, and lubricating oil is added in the lubricating oil filling pipe 19. The fully automatic intelligent surface grinder can realize automatic lubrication of a...

Embodiment 2

[0042] In the fully automatic intelligent plane grinding machine according to the embodiment of the present invention, the dual-purpose pipe 21 for blowing dust and grinding can be connected to the grinding head, and the grinding head can be hand-held for fine work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com