A method for filling the adiabatic diffusion section of a solid rocket motor

A technology of solid rocket and diffusion section, which is applied in the field of perfusion in the adiabatic diffusion section of solid rocket motor, which can solve problems such as difficult elimination of bubble defects, low fiber content of products, and unbalanced resin flow, so as to facilitate popularization and implementation and increase fiber volume fraction , The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

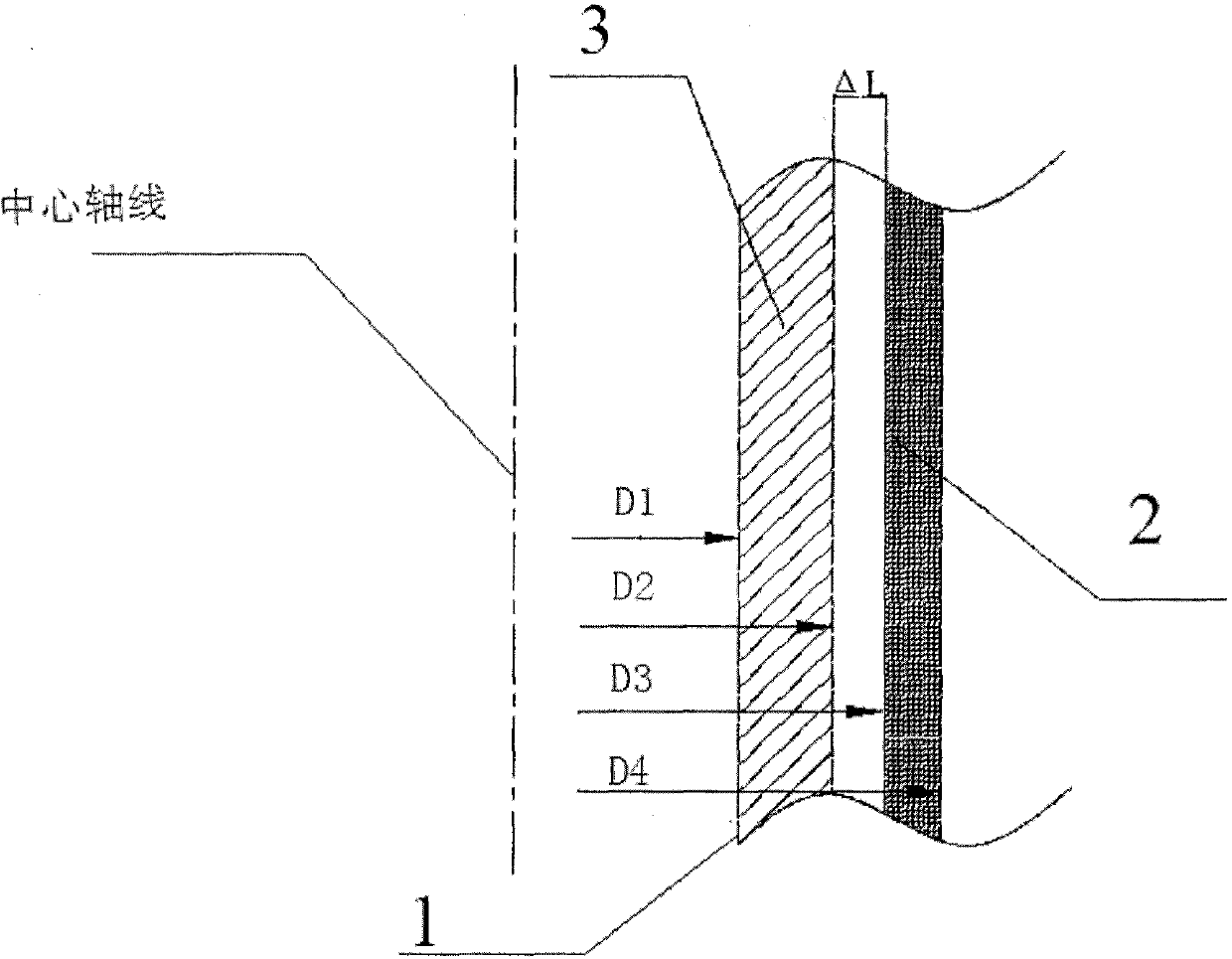

[0077] The adiabatic diffusion section of the solid rocket motor is fabricated by the silicone soft mold assisted VARTM infusion method. In the present invention, pure carbon fiber fabric is used as a reinforcing body for the heat-insulating diffusion section, and the resin is RTM phenolic resin. The expanded silicone soft mold 2 used in the production is 21mm thick, the inner diameter of the small end is 67.5mm, the inner diameter of the large end is 126mm, and the height is 91mm. During the heating process, the pressure gauge installed outside the mold showed that the applied pressure was 1 MPa.

[0078] The specific implementation steps of the above-mentioned method for forming the adiabatic diffusion section are as follows:

[0079] 1) Production of silicone soft mold. Select the metal male mold 1 with a small end diameter of 67.5 mm, a large end diameter of 126 mm, and a height of 91 mm. Apply the release agent to the metal mold, and wait for the solvent to volatilize ...

example 2

[0090] The silica gel soft mold assisted VARTM perfusion molding method involved in the present invention is similar to the method described in Example 1, and the same steps will not be repeated. The differences are:

[0091] The reinforcement used to make the thermal insulation diffusion section is composite braided carbon fiber and high-silica fiber, in which the carbon fiber is 15mm thick, and the high-silica fiber is covered on the outside of the carbon fiber with a thickness of 5mm.

[0092] The metal male mold 1 used for forming the silicone soft mold has a small end diameter of 66.5mm, a large end diameter of 125mm, and a height of 91mm, and the obtained silicone soft mold has a thickness of 22mm.

[0093] The silicone soft mold assisted VARTM infusion molding method is the same as that of Example 1, and will not be repeated here. The differences are:

[0094] In step 1), select the mold metal male mold 1 with a small end diameter of 66.5 mm, a large end diameter of 1...

example 3

[0100] The silica gel soft mold assisted VARTM perfusion molding method involved in the present invention is similar to the method described in Example 1, and the same steps will not be repeated. The differences are:

[0101] The reinforcement used to make the heat-insulating diffusion section is braided with high silica fiber, and the thickness of the carbon fiber is 20mm.

[0102] The metal male mold 1 used for forming the silicone soft mold has a small end diameter of 64.5mm, a large end diameter of 123mm, and a height of 91mm, and the obtained silicone soft mold has a thickness of 24mm.

[0103] The silicone soft mold assisted VARTM infusion molding method is the same as that of Example 1, and will not be repeated here. The differences are:

[0104] In step 1), select the mold metal male mold 1 with a small end diameter of 64.5 mm, a large end diameter of 123 mm, and a height of 91 mm. The release agent was applied three times to the metal mold. During production, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com