A molding method of a double-layer foam sandwich structure resin-based composite material

A technology of a sandwich structure and a molding method is applied in the processing field of dimension-reinforced resin-based composite materials, which can solve the problems of decreased resin flow performance, difficult to guarantee bonding quality, and high process cost, achieve high impact resistance, and meet design requirements. , The effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

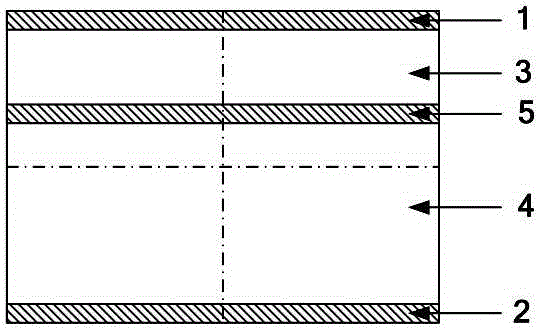

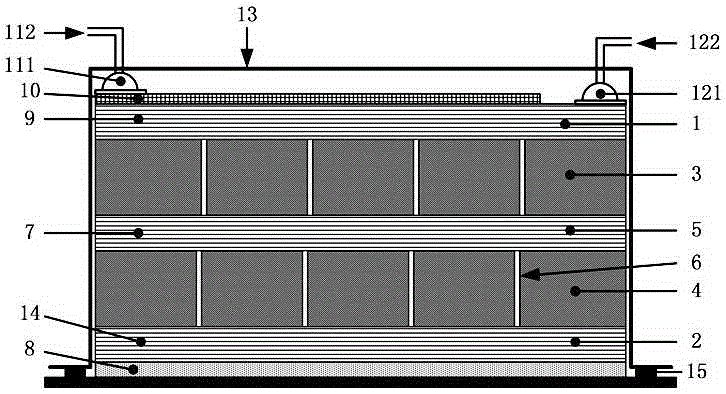

[0030] Example 1: Preparation of a double-layer foam sandwich structure resin-based composite flat plate.

[0031] a kind of like figure 2 The molding method of the double-layer foam sandwich structure resin-based composite material shown in the present invention specifically includes the following steps:

[0032] 1. Mold preparation:

[0033] On the working surface of the 500mm*500mm flat metal mold (embedded resistance wire heating system), after grinding, cleaning and processing, apply a release agent and set aside.

[0034] 2. Material preparation:

[0035] According to the product preparation requirements, prepare the corresponding reinforcing materials, RFI resin film, liquid impregnating resin, and the diversion net, release cloth, absorbent cotton, vacuum bag film 13, and sealing strip required for the vacuum injection molding process 15. Auxiliary materials such as vacuum nozzles, rubber hoses, injection hoses, and plastic collection tanks.

[0036] 2.1 RFI res...

Embodiment 2

[0059] Example 2: Preparation of a double-layer sandwich structure composite subway car hood.

[0060] 1. Mold preparation:

[0061] After grinding and cleaning the mold surface of the composite head cover with the built-in resistance wire heating system, apply a release agent and set it aside.

[0062] 2. RFI resin film preparation:

[0063] Mix 5000g of epoxy resin E-44 (a light yellow viscous liquid, purchased from Yueyang Petrochemical General Factory Epoxy Resin Factory) and 5000g of epoxy resin CYD-011 (a white transparent solid, purchased from Yueyang Petrochemical General Factory Factory epoxy resin factory) After mixing, add 8000g superfine Al(OH) 3 (white powder, provided by Zhuzhou Electric Locomotive Guangyuan Technology Co., Ltd.) and 1500g dimethyl methylphosphonate (DMMP, a colorless transparent low-viscosity liquid, purchased from Qingdao Lianmei Chemical Co., Ltd.), 400g704 curing agent (a brown-black Liquid, the main component is 2-methylimidazole and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com