Subcritical catalytic hydrolysis MC nylon method for preparing caprolactam

A technology for catalytic hydrolysis and caprolactam, applied in the preparation of lactam, chemical instruments and methods, organic chemistry, etc., can solve problems such as corrosion equipment and separation difficulties, achieve recyclable recovery, improve degradation rate, and hydrothermal stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

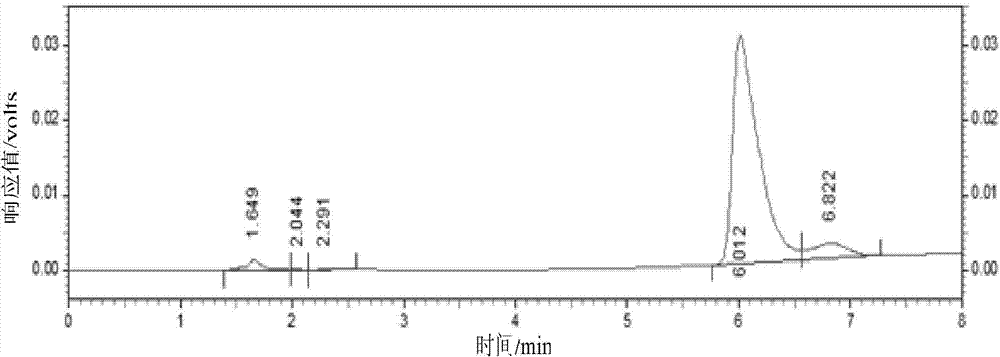

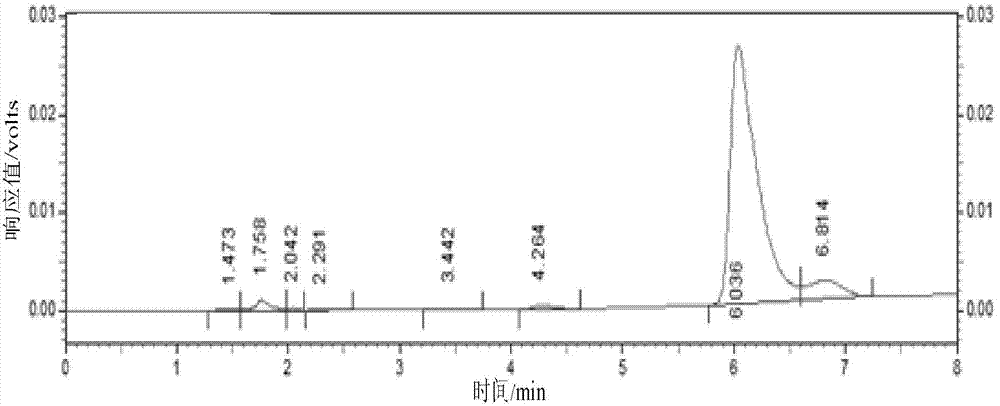

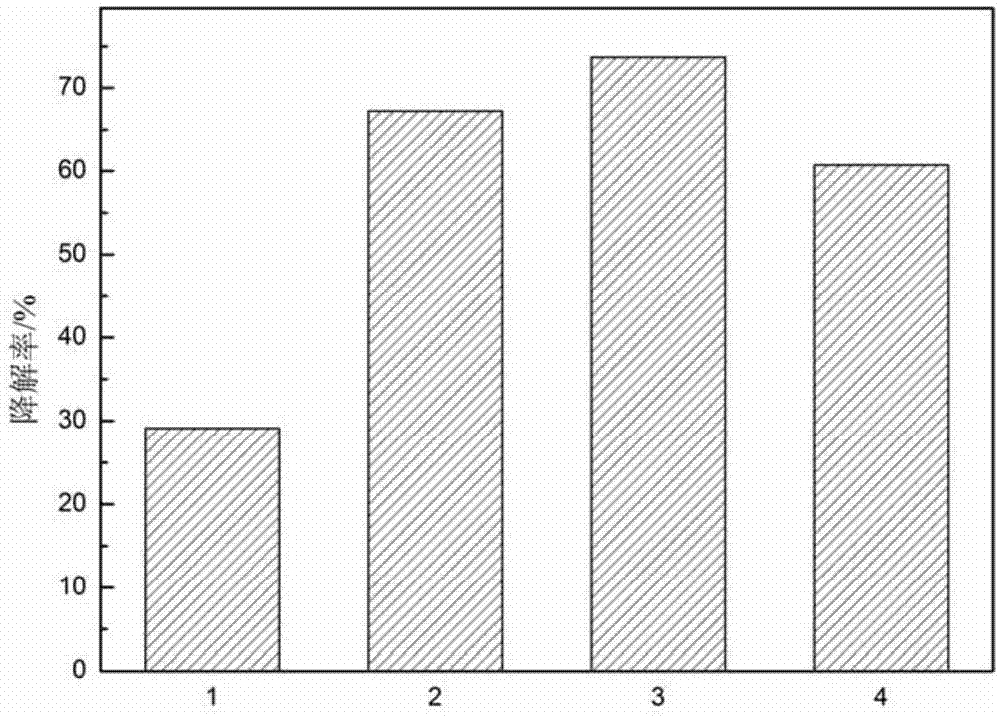

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: In this embodiment, a method for preparing caprolactam by subcritical catalytic hydrolysis of MC nylon is carried out according to the following steps:

[0019] 1. Roast the molecular sieve catalyst for 3-5 hours at a temperature of 500-600°C;

[0020] 2. Crush MC nylon, then wash with distilled water for 1-2 times, control the temperature at 50°C-70°C, and dry for 5-8h;

[0021] 3. Mix 0.1-0.6g of the molecular sieve catalyst roasted in step 1, 1.0g of MC nylon obtained in step 2 and distilled water, and add it into a stainless steel reaction kettle, seal it, wherein the solid-liquid ratio is 1g: (10-50)mL;

[0022] 4. Put the reaction kettle in step 3 into a salt bath with a temperature of 300-350° C., keep it for 20-50 minutes, and control the pressure in the kettle to be 7.0-10.0 MPa;

[0023] 5. Put the reaction kettle after the reaction in step 4 into an ice-water bath to cool to room temperature, then filter and separate the product, and...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the calcination temperature in Step 1 is 550°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the roasting time in step 1 is 4 hours. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com