Epoxy spray paint and preparation method thereof

An epoxy and epoxy resin technology, applied in the field of coatings, can solve problems such as chronic human poisoning and environmental pollution, and achieve the effect of protecting health, reducing pollution and reducing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides an environment-friendly epoxy spray paint. The weight ratio of the three components A, B and C is 100:40:10-30 when spraying.

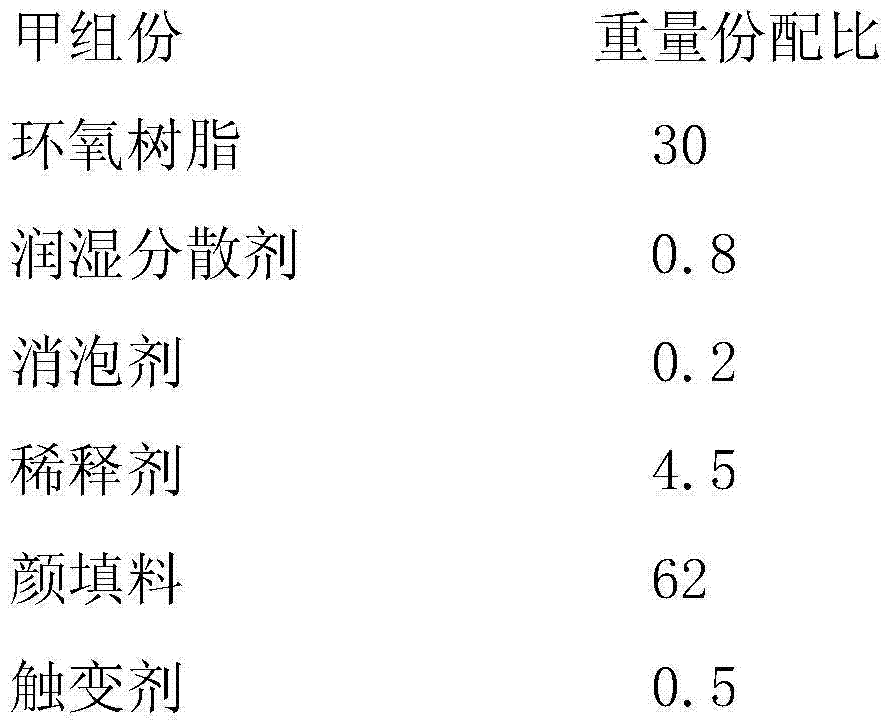

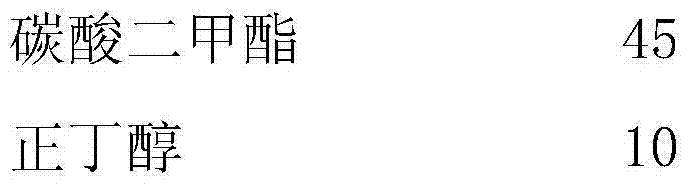

[0030]

[0031] The epoxy equivalent of the epoxy resin in the described component A is 190 grams / equivalent. The wetting and dispersing agent in the component A is a copolymer containing acidic groups. The defoamer in the said component A is a polyacrylate solution. The diluent in the described component A is glycidyl ether or benzyl alcohol. The pigments and fillers in the component A are pigments and fillers, wherein the pigments are one or more composites of organic and inorganic pigments; the fillers are mica powder, silica powder, heavy calcium, light calcium, talcum powder one or several combinations. The thixotropic agent in the first component is fumed silica. The preparation of described component A follows the steps below:

[0032] After mixing epoxy resin, wetting dispersant, defoamer and diluent, di...

Embodiment 2

[0043] This embodiment provides an environment-friendly epoxy spray paint. The weight ratio of the three components A, B and C is 100:40:10-30 when spraying.

[0044]

[0045] The epoxy equivalent of the epoxy resin in the described component A is 260 grams / equivalent. The wetting and dispersing agent in the component A is a copolymer containing acidic groups. The defoamer in the said component A is a polyacrylate solution. The diluent in the described component A is glycidyl ether or benzyl alcohol. The pigments and fillers in the component A are pigments and fillers, wherein the pigments are one or more composites of organic and inorganic pigments; the fillers are mica powder, silica powder, heavy calcium, light calcium, talcum powder one or several combinations. The thixotropic agent in the first component is fumed silica. The preparation of described component A follows the steps below:

[0046] After mixing epoxy resin, wetting dispersant, defoamer and diluent, di...

Embodiment 3

[0059] This embodiment provides an environment-friendly epoxy spray paint. The weight ratio of the three components A, B and C is 100:40:10-30 when spraying.

[0060]

[0061]

[0062]The epoxy equivalent of the epoxy resin in the described component A is 220 grams / equivalent. The wetting and dispersing agent in the component A is a copolymer containing acidic groups. The defoamer in the said component A is a polyacrylate solution. The diluent in the described component A is glycidyl ether or benzyl alcohol. The pigments and fillers in the component A are pigments and fillers, wherein the pigments are one or more composites of organic and inorganic pigments; the fillers are mica powder, silica powder, heavy calcium, light calcium, talcum powder one or several combinations. The thixotropic agent in the first component is fumed silica.

[0063] The preparation of described component A follows the steps below:

[0064] After mixing epoxy resin, wetting dispersant, defo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com