Process for dyeing silk fabric by using tuber fern wood dye

The technology of kidney fern plant and process method is applied in the field of silk products, which can solve the problems of limited application scale, long dyeing time, and low color yield, and achieve the effects of small adsorption capacity, good color fastness, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

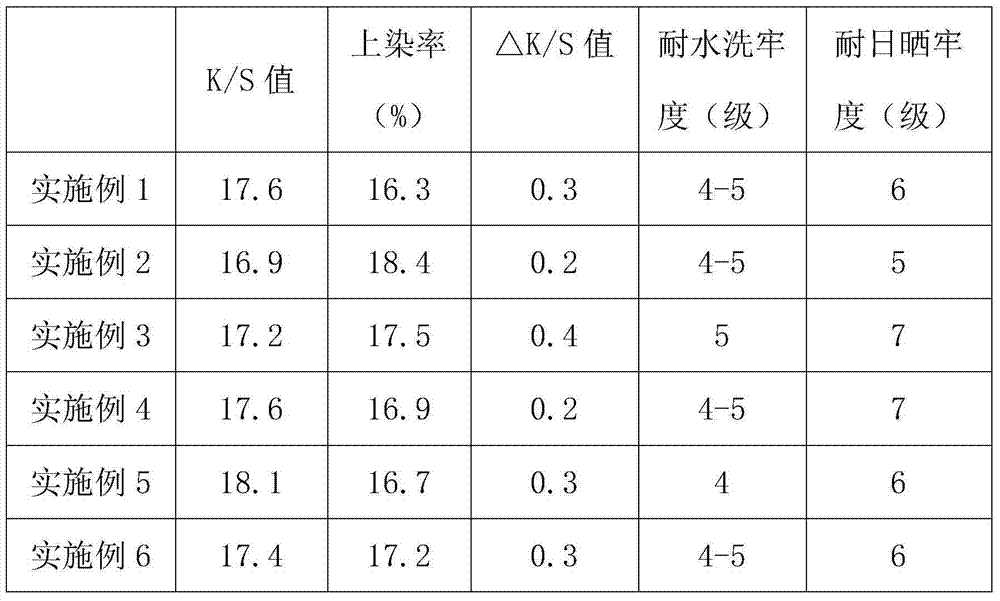

Examples

Embodiment 1

[0026] Wash the collected fern plants to remove surface impurities, dry them naturally and put them in a pulverizer to pulverize them to obtain 300-450 μm fern plant scum, pour 8 times the volume of ethanol solution into the fern plant scum, Ultrasonic treatment at 35KHz power for 20min, and then stand still to take a supernatant to obtain the kidney fern plant extract.

[0027] The kidney fern plant extract was centrifuged at a high speed of 8200rpm / min for 20min to remove the residual plant slag to obtain a secondary supernatant, and to the secondary supernatant was added chitosan with a molecular weight of 1200-2300 and stirred evenly , concentrated in vacuum for 60min under the condition of 0.1 MPa, to obtain a kidney fern plant dye with a pH value of 7, wherein the concentration of the dye is 9g / L, and the concentration of chitosan is 3g / L.

[0028] The refined mulberry silk fabric is pad-padded with kidney fern plant dye at a bath ratio of 1:50, dyed at 75°C for 80 minut...

Embodiment 2

[0030] Wash the collected fern plants to remove surface impurities, dry them naturally and put them in a pulverizer to pulverize them to obtain 300-450 μm fern plant scum, pour 10 times the volume of ethanol solution into the fern plant scum, Ultrasonic treatment at 35KHz power for 30min, and then stand still to take a supernatant to obtain the kidney fern plant extract.

[0031] Centrifuge the kidney fern plant extract at a high speed of 10000rpm / min for 10min to remove the residual plant slag to obtain a secondary supernatant, add chitosan with a molecular weight of 1200-2300 to the secondary supernatant, and stir evenly , concentrated in vacuum for 90min under the condition of 0.1 MPa to obtain the fern plant dye with a pH value of 5, wherein the concentration of the dye is 12g / L, and the concentration of chitosan is 6g / L.

[0032] Pad the refined tussah silk fabric with kidney fern plant dye at a liquor ratio of 1:50, dye it at 95°C for 50 minutes, take it out and dry it a...

Embodiment 3

[0034] Wash the collected fern plants to remove surface impurities, dry them naturally and put them in a pulverizer to pulverize to obtain 300-450 μm fern plant scum, pour 9 times the volume of ethanol solution into the fern plant scum, Ultrasonic treatment at 35KHz power for 25min, and then stand still to take a supernatant to obtain the kidney fern plant extract.

[0035] Centrifuge the kidney fern plant extract at a speed of 8500rpm / min for 15min at a high speed to remove the residual plant slag to obtain a secondary supernatant, add chitosan with a molecular weight of 1200-2300 to the secondary supernatant, and stir evenly , concentrated under vacuum for 70min under the condition of 0.1 MPa to obtain a kidney fern plant dye with a pH value of 6, wherein the concentration of the dye is 10g / L, and the concentration of chitosan is 5g / L.

[0036] The refined regenerated silk fabric is pad-padded with kidney fern plant dye at a liquor ratio of 1:50, dyed at 80°C for 60 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com