Dyeing auxiliary and preparing process thereof

A technology of dyeing auxiliaries and preparation process, which is applied in the direction of dyeing method, dyeing low-molecular-weight organic compound treatment, textile and paper making, etc. Dyeing rate and dyeing fastness, simple process, and the effect of improving dye utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0047] First, in-situ suspension polymerization was used to prepare PS-montmorillonite particles containing different proportions of bentonite. It has the following properties:

[0048] (l) It has the ability to adsorb certain cations and anions and maintain them in an exchanged state.

[0049] (2) The action of clay minerals and water can produce swelling, dispersion and cohesion, viscosity, thixotropy and plasticity.

[0050] (3) Clay minerals can react with organic matter to form organic complexes.

[0051] As mentioned above, dyeing auxiliaries can improve performance and expand the range of applications.

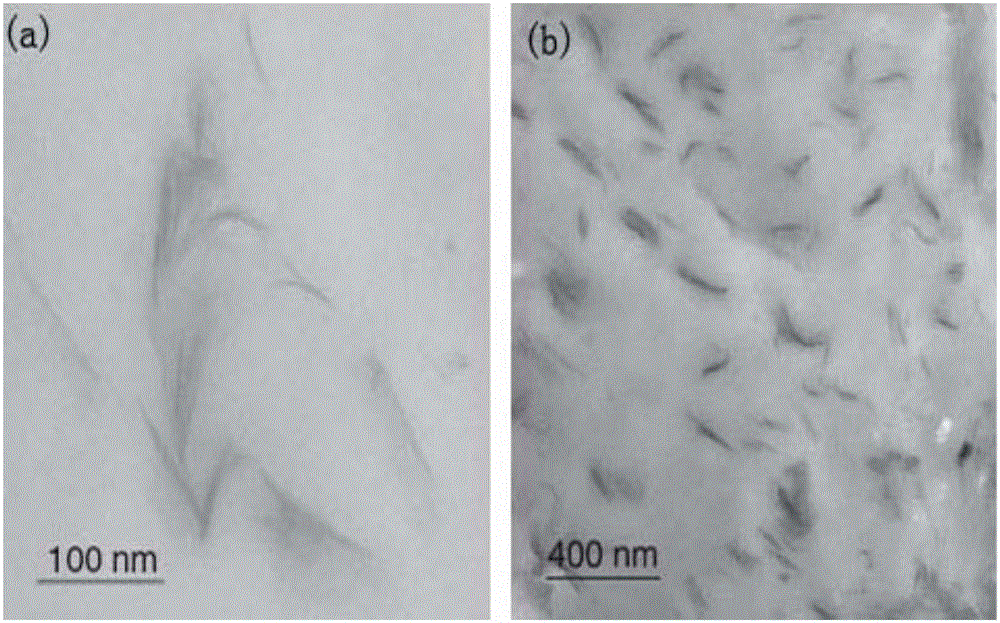

[0052] Such as figure 2 As shown in (a) and (b), the organically modified montmorillonite is uniformly dispersed in the polymer, which means that the organic modification of the montmorillonite can improve the compatibility of the montmorillonite and the spinning matrix.

experiment example 2

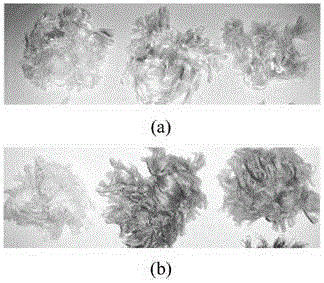

[0054] In the experimental examples, the dyeing conditions of chemical fibers before and after using the dyeing auxiliaries of the present application are compared. Such as image 3 (a) and (b) ( image 3 (a) is the fiber dyeing effect without adding dyeing auxiliaries, image 3 (b) is the dyeing effect of adding 3% of the dyeing auxiliaries), using the dyeing auxiliaries of the present application can greatly improve the dye uptake and color fastness of the dye. In this experimental example, the suggested addition amount is 2-5%.

[0055] Compared with the prior art, the present application can obtain the following technical effects:

[0056] 1) The specific surface area of the dyeing auxiliaries of this application can reach 180m 2 / g, has very good activity and can improve the combination degree of dyeing auxiliaries and dyes.

[0057] 2) The dyeing auxiliaries of the present application can effectively improve dye uptake and color fastness.

[0058] 3) The dyeing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com