Printing paste for seaweed fiber fabric, and preparation method and application thereof

A technology for printing color paste and seaweed fiber, applied in the field of dyeing, can solve the problem that the printing process of seaweed fiber fabric has not been developed, and achieve the effects of improving the dyeing rate and color fastness, simple equipment and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

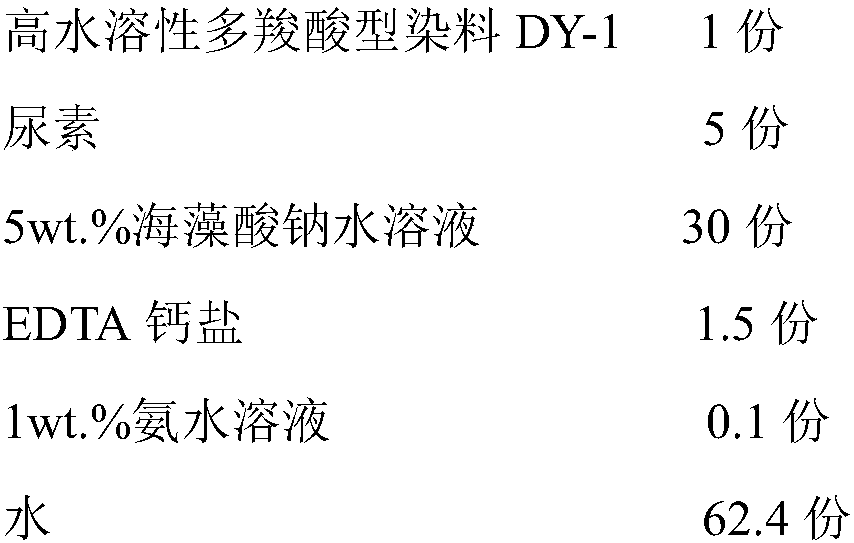

[0036] The printing paste for seaweed fiber fabric is made of the following raw materials in parts by weight:

[0037]

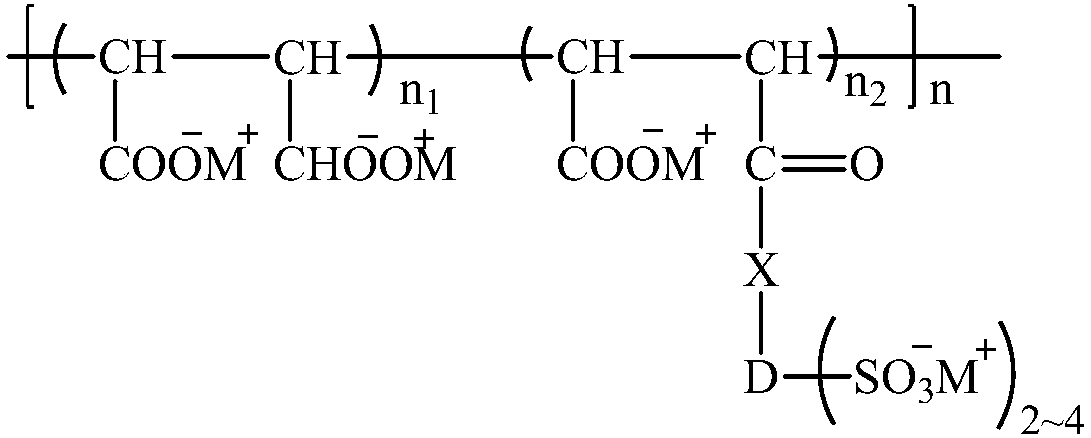

[0038] The structural formula of the highly water-soluble polycarboxylic acid dye DY-1 is:

[0039]

[0040] where: n 1 =20-30, n 2 =20-30, n=200-250.

[0041] The preparation method of printing paste for described seaweed fiber fabric is as follows:

[0042] Add urea to 5wt.% sodium alginate aqueous solution, mix well to obtain A solution; dissolve highly water-soluble polycarboxylic acid dye DY-1 in water, add 1wt.% ammonia solution to adjust the pH value to 6.5, and then add EDTA Calcium salt, stirred evenly to obtain solution B; mixing solution A and solution B, beating and homogenizing to obtain printing paste.

[0043] The printing paste is applied to the flat screen printing of the seaweed fiber fabric: the seaweed fiber fabric is printed with the printing paste, then the seaweed fiber fabric is baked at 85°C for 4 minutes, then steamed at 1...

Embodiment 2

[0045] The highly water-soluble polycarboxylic acid dye DY-1 in Example 1 is changed to the highly water-soluble polycarboxylic acid dye DY-2, and the rest of the steps are the same as in Example 1.

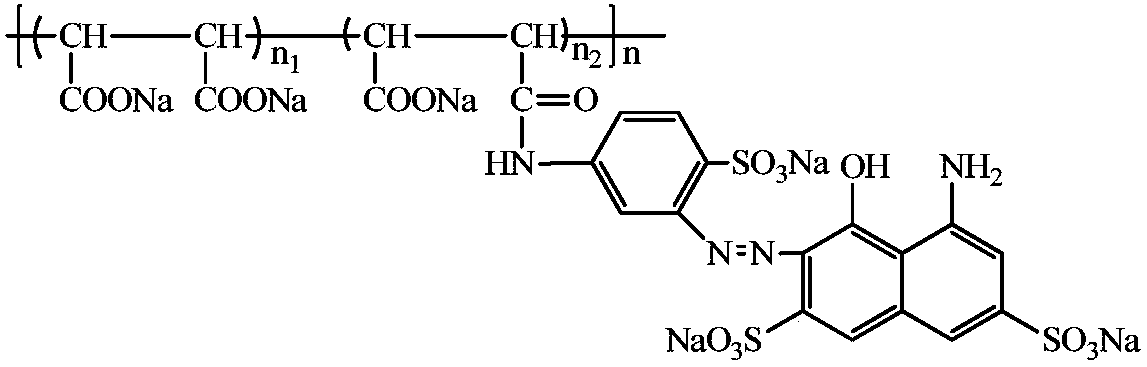

[0046] The structural formula of the highly water-soluble polycarboxylic acid dye DY-2 is:

[0047]

[0048] where: n 1 =40-50, n 2 =40-50, n=100-130.

Embodiment 3

[0050] The highly water-soluble polycarboxylic acid dye DY-1 in Example 1 is changed to the highly water-soluble polycarboxylic acid dye DY-3, and the rest of the steps are the same as in Example 1.

[0051] The structural formula of the highly water-soluble polycarboxylic acid dye DY-3 is:

[0052]

[0053] where: n 1 =40-50, n 2 =60-70, n=80-100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com