A deep-hole karst grouting aided extubation device and construction method

A construction method and grouting technology, which can be applied in basic structure engineering, soil protection, sheet pile walls, etc., can solve the problems of steel sleeves locked, unable to rotate and pull out, steel sleeves cannot be reused, etc., to achieve The effect of reducing cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with embodiment.

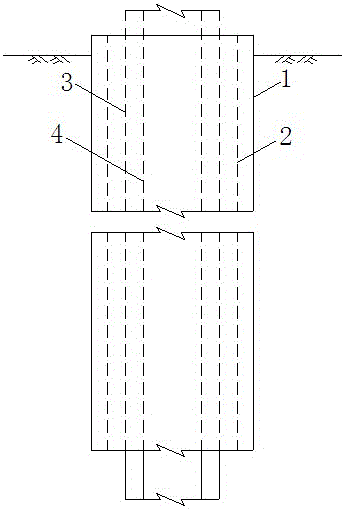

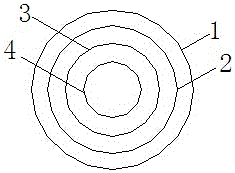

[0013] Embodiments of the present invention: the deep hole karst grouting auxiliary pipe pulling device of the present invention comprises a large drill pipe 1, an outer pipe 2, a steel casing 3 and a small drill pipe 4, the diameter of the large drill pipe 1 is greater than the diameter of the outer pipe 2, the diameter of the outer pipe 2 The diameter of the pipe 2 is larger than the diameter of the steel casing 3, the diameter of the steel casing 3 is larger than the diameter of the small drill pipe 4, the outer pipe 2 is shorter than the steel casing 3, the outer pipe 2 is arranged outside the steel casing 3, and the steel casing 3 is placed on the base Below the rock face.

[0014] The diameter of the large drill pipe 1 is Φ250mm; the outer pipe 2 is a PVC pipe with a diameter of Φ200mm, each section is 4m long and the wall thickness is 6.2mm; the diameter of the steel casing 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com