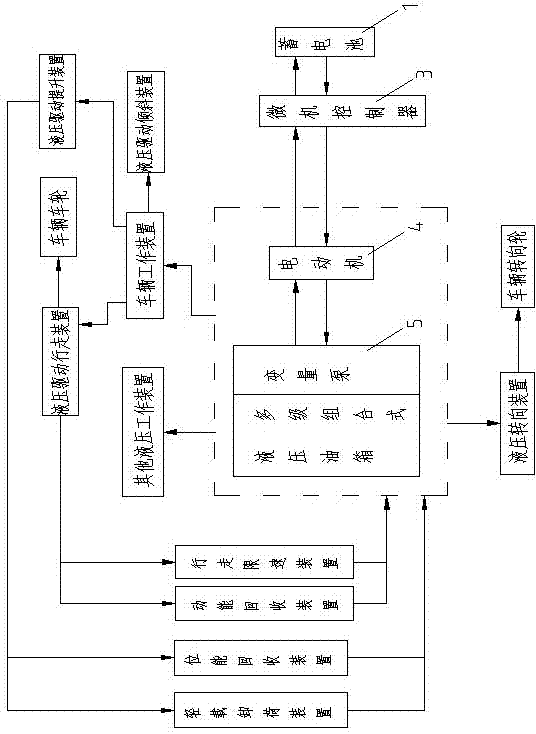

Electronic control hydraulic driving system used for industrial vehicles

An electronically controlled hydraulic and drive system technology, applied in electric braking systems, fluid pressure actuation system components, vehicle components, etc., can solve problems such as increased cost and energy consumption, low power factor of AC motors, affecting loading and unloading efficiency, etc. Achieve the effect of improving discharge capacity efficiency, reducing hydraulic system noise, and avoiding throttling speed loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

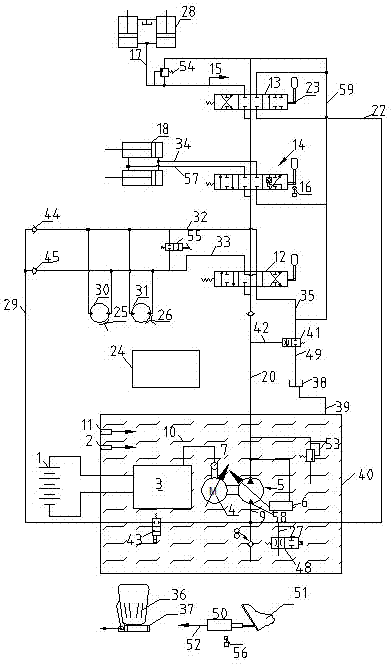

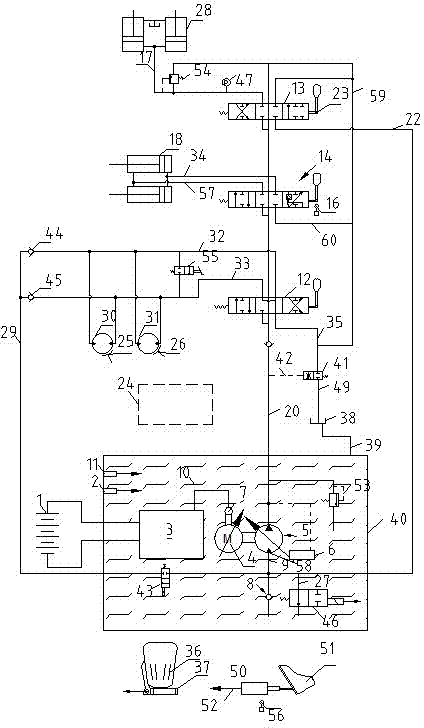

Embodiment 1

[0052] Walking operation: when the vehicle is running forward, the handle of the walking reversing valve 12 is placed in the forward gear position, the accelerator pedal 36 is stepped on, and the accelerator pedal 36 drives the acceleration sensor 37 to send a signal to the microcomputer controller 3, and the microcomputer controller 3 generates a corresponding frequency and The voltage signal drives the motor 4 to rotate, drives the variable pump 5 to output corresponding hydraulic oil, and drives the hydraulic motors 30, 31 to work through the oil pipe 20, the travel reversing valve 12, the oil pipe 32. Hydraulic motors 30, 31 pass oil pipe 33, travel reversing valve 12, oil pipe 35, speed limit valve 41 (hydraulic oil pressure in oil pipe 20 rises, and speed limit valve 41 is pushed to open through oil pipe 42), oil pipe 49, oil return tank 38 , The fuel tank 38 is communicated with the fuel tank 40 to complete the walking drive. The rotation speed of the hydraulic motor is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com