Magnetic leakage corrosion track detector for inner wall of pipeline

A magnetic flux leakage detection and detector technology, applied in pipeline systems, instruments, measuring devices, etc., can solve problems such as difficult speed control, increased counting error, mileage wheel slippage, etc., and achieves compact structure, strong coupling ability, and reliability and effectiveness strongly supported by the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

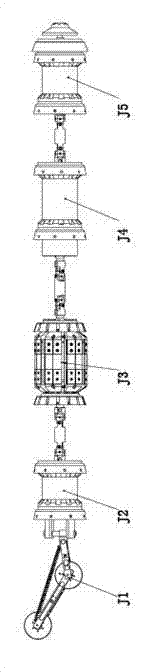

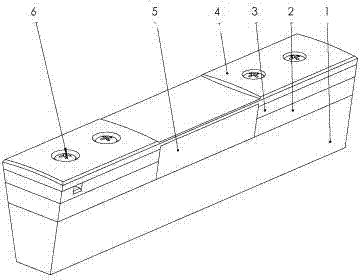

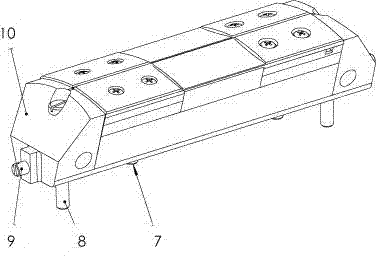

[0028] according to Figure 1 to Figure 7 The present invention is described in detail. The battery section J5, the computer section J4, the magnetic flux leakage detection probe section J3, the positioning section J2, and the mileage wheel section J1 described in the figure are arranged in sequence, and the adjacent two sections are connected by a positioning coupling; the magnetic flux leakage detection probe Section J3 includes a magnetic flux leakage section skeleton 11 arranged axially and with mounting flanges at both ends. Probe brackets 10 are evenly distributed along the circumference between the two ends of the flanges, and an integrated probe is arranged in the probe bracket 10; The two ends of each probe bracket are provided with an upper limit post 9 that can slide in the flange groove on the magnetic flux leakage joint skeleton 11, and the bottom of the two ends of the probe bracket is also provided with a sliding up and down in the corresponding hole on the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com