Evaluation instrument for damage of aqueous phase trapping of high-temperature high-pressure tight gas reservoir

A high-temperature, high-pressure, tight gas technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems that have not yet been formed, and the relative permeability test method cannot use tight cores, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further illustrate the present invention according to accompanying drawing below.

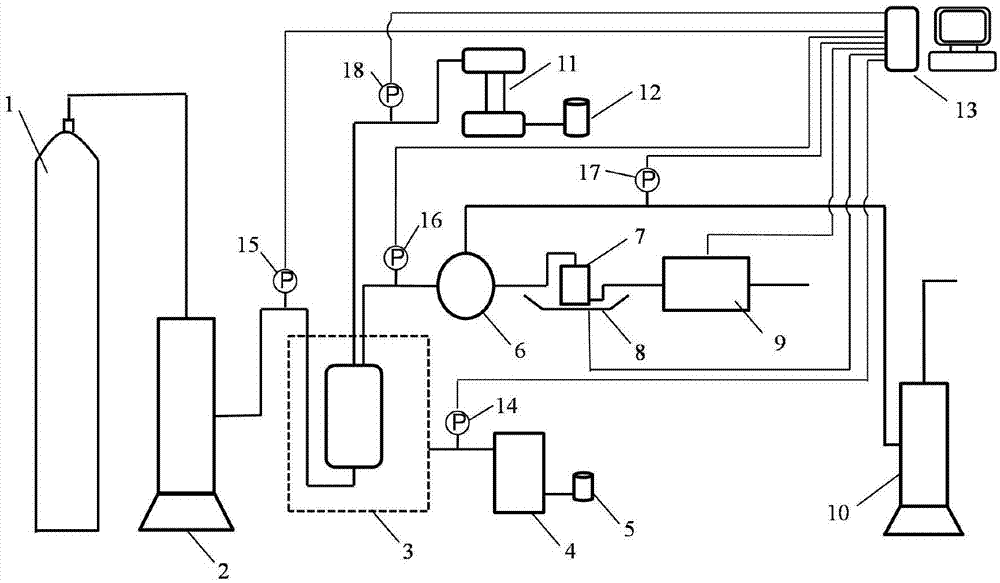

[0019] The high-temperature and high-pressure tight gas reservoir water phase trap damage evaluation instrument is mainly composed of a core holder system, a liquid displacement system, a gas displacement system, a gas-liquid metering system and a data acquisition system.

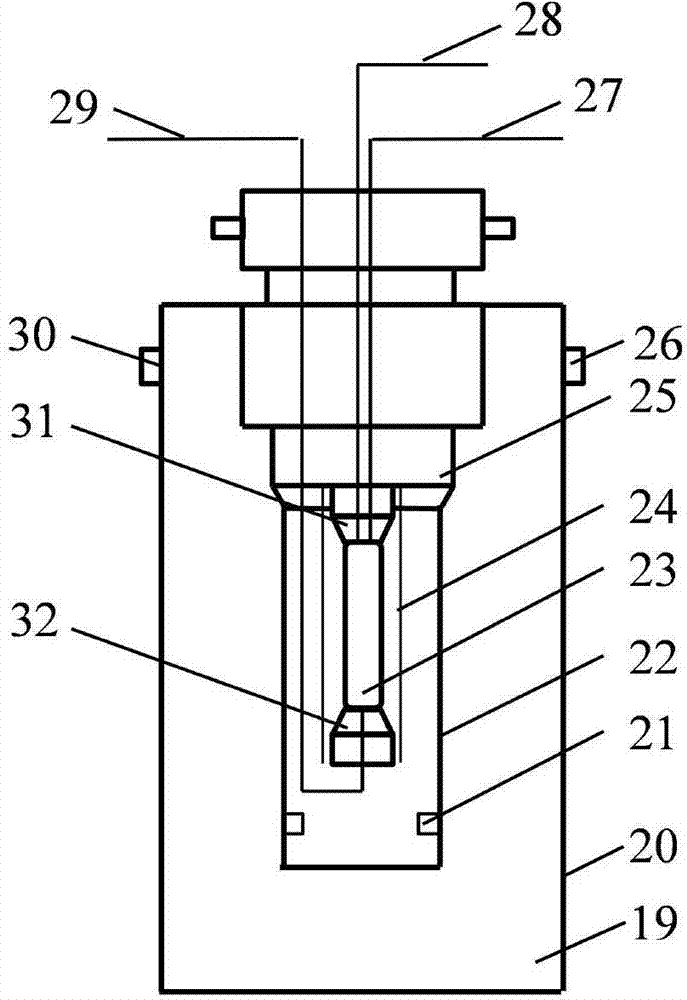

[0020] The core holder system is composed of a core holder 3, a confining pressure pump 4, an oil tank 5, a confining pressure sensor 14 and a heating / temperature control device 21. The rock core holder 3 consists of a kettle body 19, an end cover 25, The rubber sleeve 24 and the plunger 32 are composed. The kettle body 19 is connected with the confining pressure pump 4, the oil tank 5 and the confining pressure sensor 14. There is a heating / temperature control device 21 at the groove of the wall 22 in the kettle body, and the kettle body 19 has an end The cover 25 and the end cover 25 have three openings, which are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com