A method for desalting from antimicrobial lipopeptide solution using low-temperature freezing environment

An antibacterial lipopeptide and low-temperature freezing technology, applied in the field of antibacterial peptide purification, can solve the problems of off-tail peaks, low product purity, high toxicity of organic solvents, etc., and achieve the effects of easy mastery, easy operation skills, and low operation technical difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

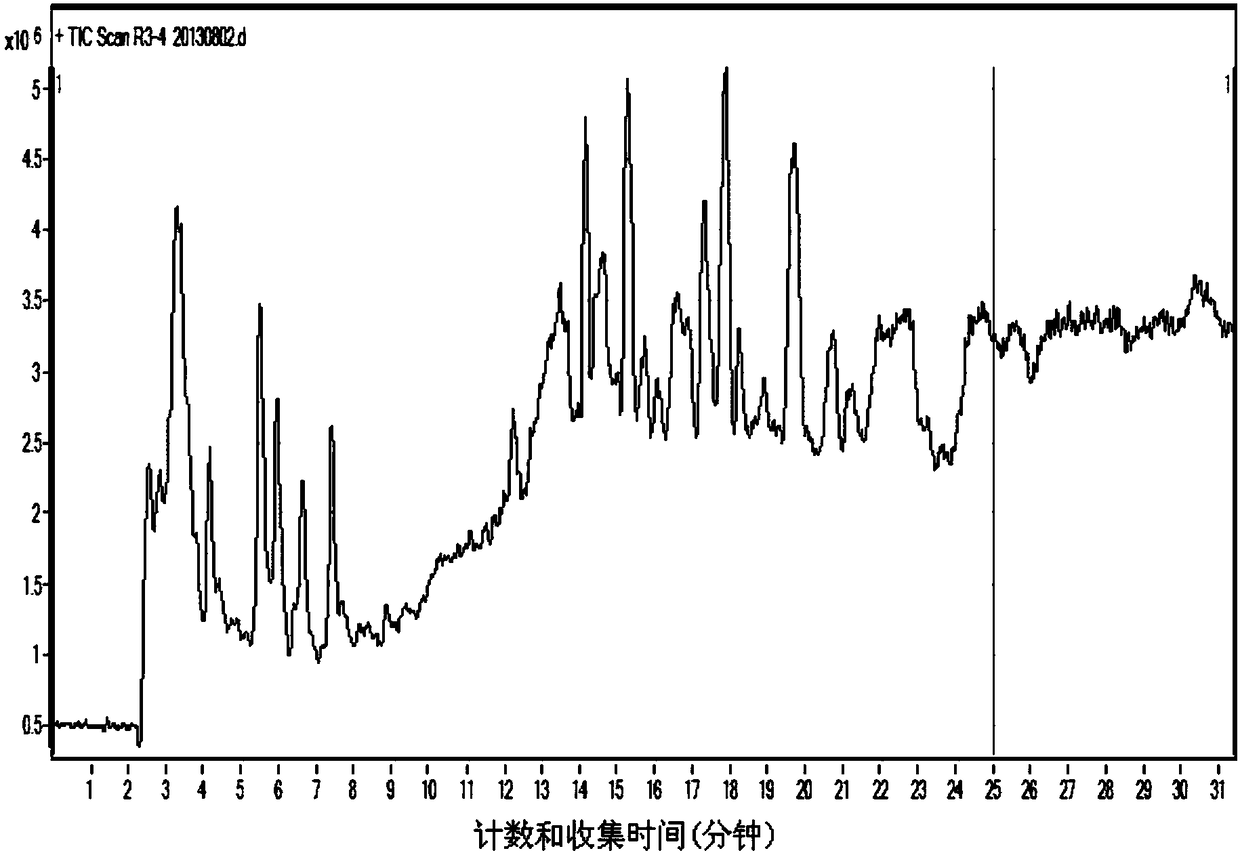

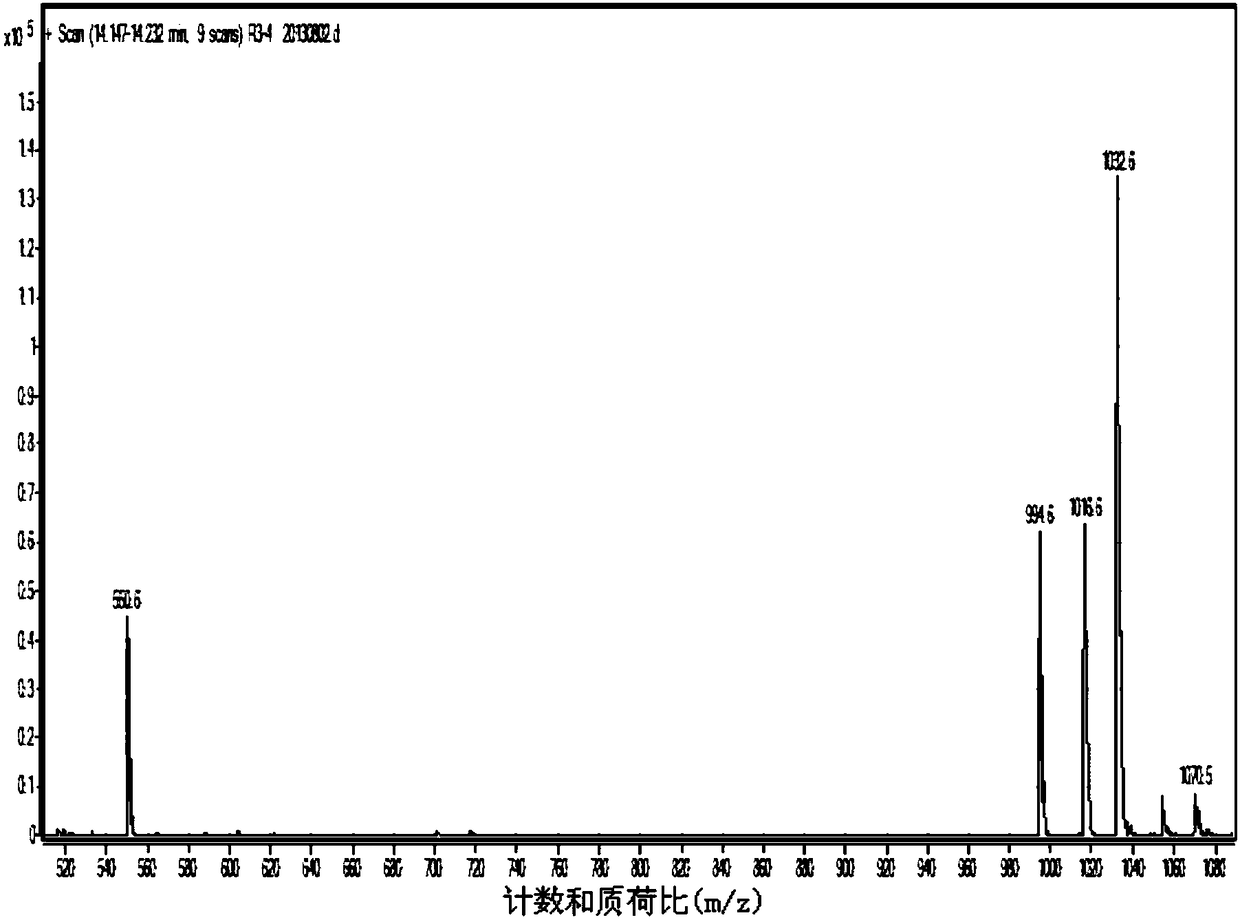

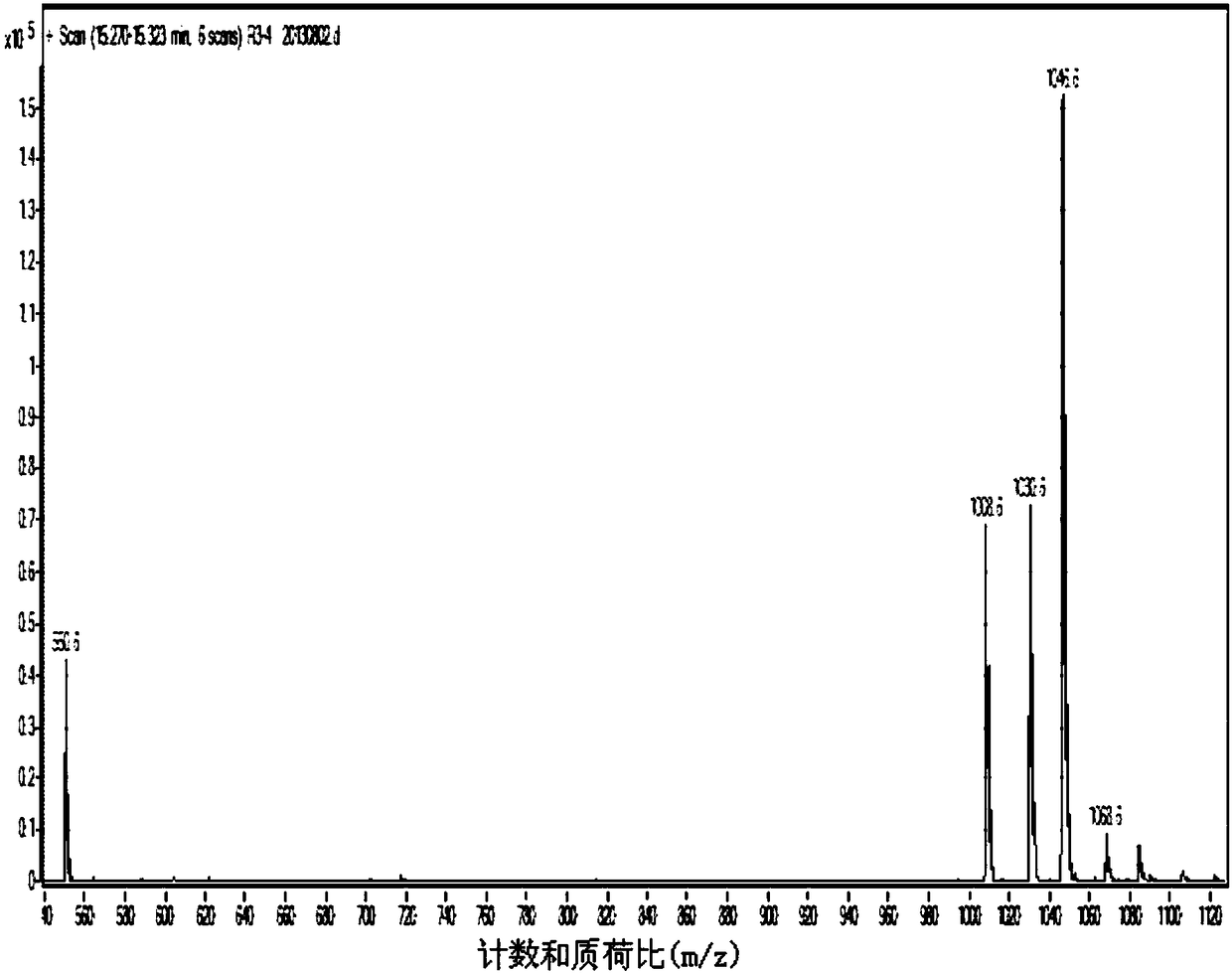

Image

Examples

Embodiment Construction

[0016] Technical scheme of the present invention is as follows:

[0017] A method for desalting from an antibacterial lipopeptide solution using a low-temperature freezing environment, characterized in that it comprises the steps of:

[0018] (1) The fermented liquid obtained after fermenting Bacillus amyloliquefaciens to prepare the antibacterial lipopeptide is filtered to remove the thalline to obtain a clarified liquid;

[0019] (2) Add dilute hydrochloric acid to the clarified liquid obtained in step (1) until the pH value is 1.8 to 2.5, leave it at room temperature for more than 16 hours, discard the supernatant, and obtain a slurry fluid;

[0020] (3) Add extractant to the slurry fluid obtained in step (2), the addition of extractant is 5%~10% of the fermentation liquid volume in step (1), stir well, 0~20 ℃ extract 3~ After 5 hours, after centrifugation, the filtrate was obtained by microfiltration through a 0.22 micron organic membrane;

[0021] Described extraction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com