Shell utilization method

A technology of shells and shell powder, applied in the application, animal feed, animal feed and other directions, can solve the problems of non-renewable mine resource destruction, unstable calcium content, difficult to absorb, etc. , excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

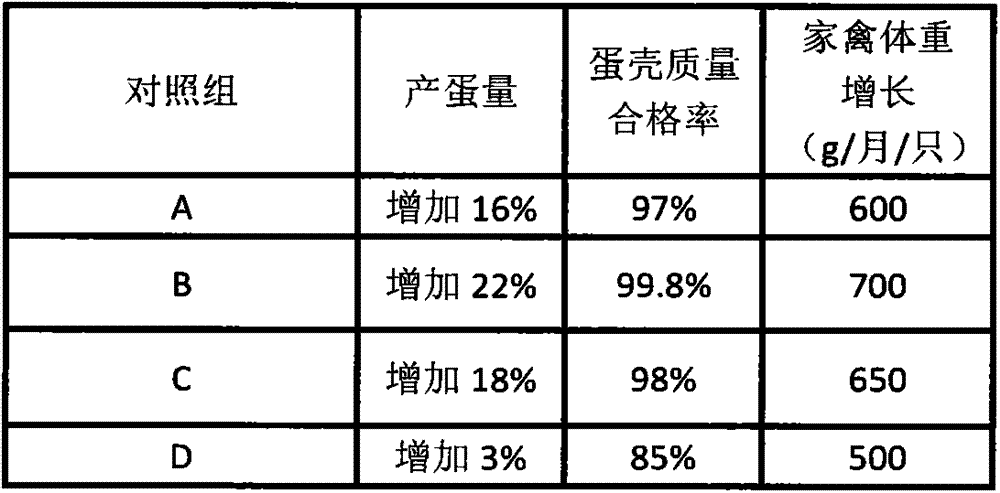

Examples

Embodiment 1

[0026] A shell utilization method, comprising the following steps:

[0027] Step 1: Wash

[0028] Remove the residual sundries from the shells, wash them thoroughly, then scrub them in alkaline water to remove the grease, then rinse them with clean water to remove the alkalinity, and rinse until neutral;

[0029] Step 2: Grinding

[0030] Drain the shells obtained in step 1; put them in a ball mill tank, add distilled water, and ball mill;

[0031] Step 3: Sterilization

[0032] Take out the ground shells, put them on a plate and spread them evenly, then bake them in a constant temperature oven at a high temperature, the baking temperature is controlled at 120°C, when the surface of the shells turns yellow and there is a crackling sound, cut off the power, and cool down to 60°C quickly take out;

[0033] Step 4: Crush and sieve

[0034] Grind it with a pulverizer while it is hot, heat it in an oven, grind it and sieve it;

[0035] Step 5: Stir Fry

[0036] Put the shell...

Embodiment 2

[0040] A shell utilization method, comprising the following steps:

[0041] Step 1: Wash

[0042] Remove the residual sundries from the shells, wash them thoroughly, then scrub them in alkaline water to remove the grease, then rinse them with clean water to remove the alkalinity, and rinse until neutral;

[0043] Step 2: Grinding

[0044] Drain the shells obtained in step 1; put them in a ball mill tank, add distilled water, and ball mill;

[0045] Step 3: Sterilization

[0046] Take out the ground shells, put them on a plate and spread them evenly, then bake them in a constant temperature oven at a high temperature, the baking temperature is controlled at 145°C, when the surface of the shells turns yellow and there is a crackling sound, cut off the power, and cool down to 65°C quickly take out;

[0047] Step 4: Crush and sieve

[0048] Grind it with a pulverizer while it is hot, heat it in an oven, grind it and sieve it;

[0049] Step 5: Stir Fry

[0050] Put the shell...

Embodiment 3

[0054] A shell utilization method, comprising the following steps:

[0055] Step 1: Wash

[0056] Remove the residual sundries from the shells, wash them thoroughly, then scrub them in alkaline water to remove the grease, then rinse them with clean water to remove the alkalinity, and rinse until neutral;

[0057] Step 2: Grinding

[0058] Drain the shells obtained in step 1; put them in a ball mill tank, add distilled water, and ball mill;

[0059] Step 3: Sterilization

[0060] Take out the ground shells, put them on a plate and spread them evenly, and then bake them in a constant temperature oven at a high temperature. The baking temperature is controlled at 160°C. When the surface of the shells turns yellow and there is a crackling sound, cut off the power supply and cool down to 70°C quickly. take out;

[0061] Step 4: Crush and sieve

[0062] Grind it with a pulverizer while it is hot, heat it in an oven, grind it and sieve it;

[0063] Step 5: Stir Fry

[0064] Pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com