Shredding method and shredding blade capable of controlling distribution of tobacco shred lengths

A technology of cut tobacco length and cutting blade, applied in the field of cutting technology, can solve the problems of reducing the filling value of cut tobacco, increasing the amount of cut tobacco at the end of cigarettes, cigarette density, combustion temperature, negative effects on sensory quality, etc., and reducing the amount of cut tobacco used. , Improve the utilization rate of raw materials, improve the effect of sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings, but not limited to the embodiments.

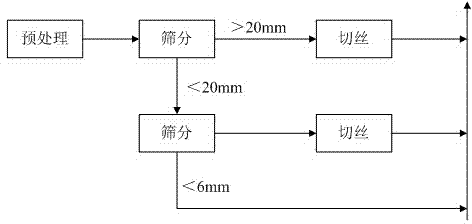

[0036] The shredding method that can control the length distribution of cut tobacco is carried out in the following steps (such as figure 1 shown):

[0037] (1) Pretreatment: According to the existing technology in the silk production line, the tobacco materials that need to be shredded are loosened, regained moisture, and added, so that the temperature and moisture content meet the shredded requirements;

[0038] (2) Screening: Screen the pretreated tobacco material with a 20mm screen, and screen the material smaller than 20mm for a second screening with a 6mm screen. The secondary screening after reducing the flow rate can Improve the sieving efficiency of tobacco sheets smaller than 6mm, so that the sieved smoke sheets smaller than 6mm can reach about 6% of the total material volume, thereby reducing the shredded shred rate gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com