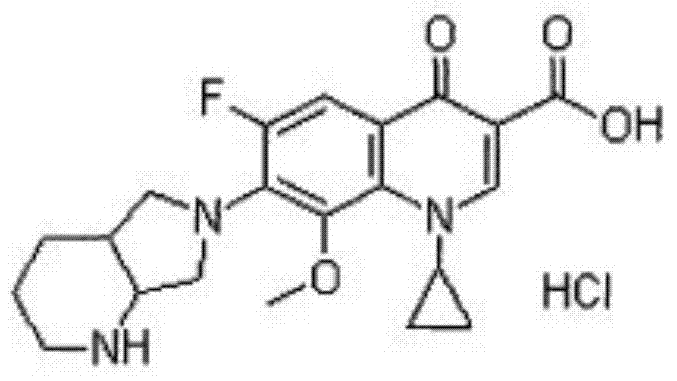

Steady moxifloxacin hydrochloride injection

A technology of moxifloxacin hydrochloride and moxifloxacin, which is applied in the field of new moxifloxacin hydrochloride injection and its preparation, can solve the problems of discoloration, poor storage stability of preparations, and enlargement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

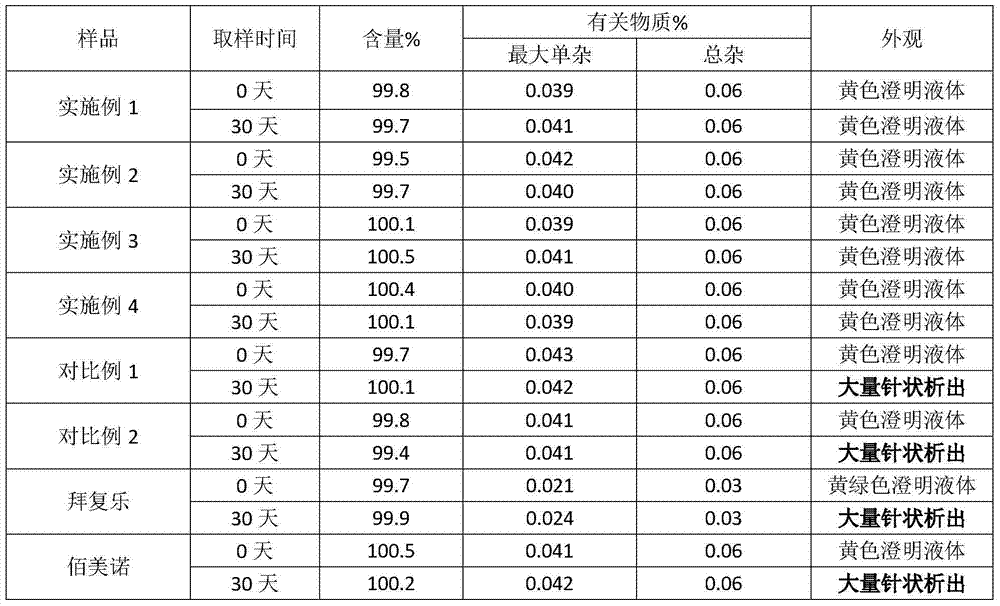

Examples

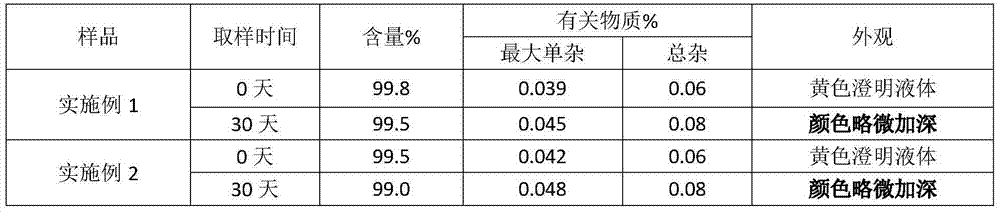

Embodiment 1

[0016] Moxifloxacin Hydrochloride Injection (20ml:0.4g)

[0017] prescription

[0018] Moxifloxacin hydrochloride 40g (calculated as moxifloxacin)

[0019] PEG200 13g

[0020] Appropriate amount of sodium hydroxide

[0021] Add water for injection to 2000ml

[0022] A total of 100 sticks were prepared

[0023] Preparation process: Take about 800ml of water for injection, adjust the water temperature to 50-60°C, add the prescribed amount of moxifloxacin and PEG200, stir to dissolve, adjust the pH to 5.5 with 2mol / L sodium hydroxide solution, and make up water for injection to Full amount. Add 0.5% activated carbon to adsorb for 30 minutes, filter and decarbonize; the liquid medicine is filtered through 0.45 μm and 0.22 μm filter membranes respectively; after potting, it is sterilized by flowing steam at 121°C / 15min. Moxifloxacin hydrochloride injection was obtained.

Embodiment 2

[0025] Moxifloxacin Hydrochloride Injection (20ml:0.4g)

[0026] prescription

[0027] Moxifloxacin hydrochloride 40g (calculated as moxifloxacin)

[0028] PEG200 65g

[0029] Appropriate amount of sodium hydroxide

[0030] Add water for injection to 2000ml

[0031] A total of 100 sticks were prepared

[0032] Preparation process: Take about 800ml of water for injection, adjust the water temperature to 50-60°C, add the prescribed amount of moxifloxacin and PEG200, stir to dissolve, adjust the pH to 4.5 with 2mol / L sodium hydroxide solution, and make up water for injection to Full amount. Add 0.5% activated carbon to adsorb for 30 minutes, filter and decarbonize; the liquid medicine is filtered through 0.45 μm and 0.22 μm filter membranes respectively; after potting, it is sterilized by flowing steam at 121°C / 15min. Moxifloxacin hydrochloride injection was obtained.

Embodiment 3

[0034] Moxifloxacin Hydrochloride Injection (20ml:0.4g)

[0035] prescription

[0036] Moxifloxacin hydrochloride 40g (calculated as moxifloxacin)

[0037] Appropriate amount of sodium hydroxide

[0038] PEG200 300g

[0039] Add water for injection to 2000ml

[0040] A total of 100 sticks were prepared

[0041] Preparation process: Take about 800ml of water for injection, adjust the water temperature to 50-60°C, add the prescribed amount of moxifloxacin and PEG200, stir to dissolve, adjust the pH to 4.5 with 2mol / L sodium hydroxide solution, and make up water for injection to Full amount. Add 0.5% activated carbon to adsorb for 30 minutes, filter and decarbonize; filter the liquid medicine through 0.45 μm and 0.22 μm filter membranes; Moxifloxacin hydrochloride injection was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com