Salt-manufacturing anti-deposition agent and method for preventing salt-manufacturing equipment from scale deposition

An anti-deposition agent and equipment technology, used in chemical instruments and methods, descaling and water softening, special treatment targets, etc., can solve problems such as corrosion of heaters and evaporation tanks, and difficult to brush off the scale layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A method for preventing scale deposition on salt making equipment includes the following:

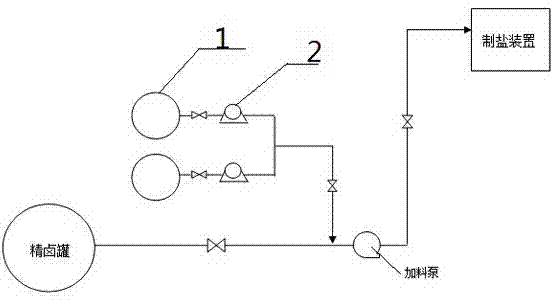

[0020] 1) In the production process of salt making equipment, such as figure 1 In the process, the salt-making anti-sedimentation agent is added to the ton barrel 1, and then the electromagnetic pump 2 on the ton barrel 1 pumps the anti-sedimentation agent from the ton barrel 1 into the inlet pipeline of the brine pump, and the anti-sedimentation agent enters the heating with the brine evaporator and evaporator. The flow rate used by the anti-deposition agent is adjusted by manually adjusting the valve opening of the electromagnetic pump;

[0021] 2) When the pH value of the salt making equipment liquid is greater than 11, add anti-sedimentation agents containing hydroxy acid salt-sulfonate-nonionic terpolymer, HPMA, PAA, or use PASP, polymaleic acid, hydroxy Anti-deposition agent composed of salt-sulfonate-nonionic terpolymer and PAA.

[0022] A salt-making anti-deposition ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com