A kind of carbon fiber reinforced polylactic acid composite material and its preparation method and application

A technology of composite materials and polylactic acid, applied in transportation and packaging, substructure, vehicle parts, etc., can solve the problems of limited mechanical properties and low production efficiency, and achieve excellent mechanical properties, simple operation, and good appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

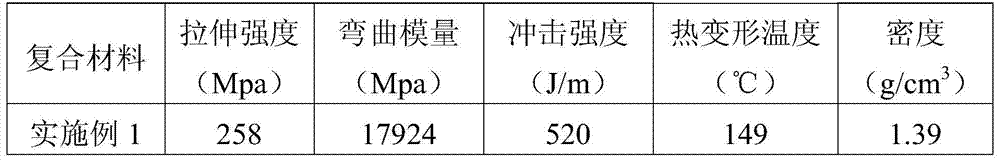

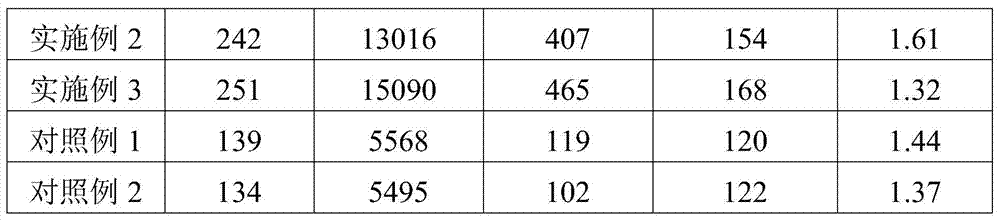

Examples

Embodiment 1

[0037] The carbon fiber reinforced polylactic acid composite material of this embodiment is composed of the following components by weight: 40 parts of modified carbon fiber, 60 parts of D-polylactic acid with a weight average molecular weight of 250000, 3 parts of phenyltrimethoxysilane, antioxidant 10101.5 parts of lubricant, 0.5 part of lubricant EBS, and 2920.2 parts of light stabilizer; among them, the modified carbon fiber is obtained by sequentially performing oxidation modification and graft modification on carbon fiber, and the oxidation modification is to make the carbon fiber in 65wt% Nitric acid solution was treated at 60°C for 5 minutes, and the grafting modification was to treat the carbon fiber in 45 wt% sodium tetrafluoroborate aqueous solution at 90°C for 5 minutes.

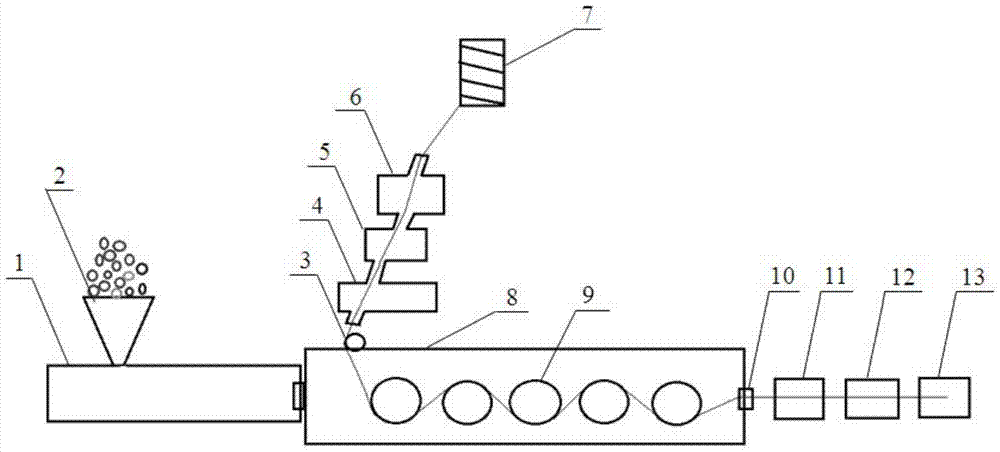

[0038] like figure 1 As shown, the carbon fiber reinforced polylactic acid composite material can be prepared by the following method:

[0039] 1. Preparation of modified carbon fiber

[0040] ...

Embodiment 2

[0047] The carbon fiber reinforced polylactic acid composite material of this embodiment is composed of the following components by weight: 20 parts of modified carbon fiber, 80 parts of polylactic acid with a weight average molecular weight of 500000, γ-methacryloxypropyl trimethyl 4 parts of oxysilane, 1682 parts of antioxidant, 0.8 part of lubricant EBS, and 7700.5 parts of light stabilizer; wherein, the modified carbon fiber is obtained by sequentially oxidizing and grafting the carbon fiber, and the oxidation modification The property is to treat the carbon fiber in a 55wt% nitric acid solution at 70°C for 8 minutes, and the graft modification is to treat the carbon fiber in a 55wt% sodium tetrafluoroborate aqueous solution at 110°C for 5 minutes.

[0048] The carbon fiber reinforced polylactic acid composite material can be prepared by the following method:

[0049] 1. Preparation of modified carbon fiber

[0050] Put the carbon fiber in 55wt% nitric acid solution, modi...

Embodiment 3

[0056] The carbon fiber reinforced polylactic acid composite material of this embodiment is composed of the following components by weight: 50 parts of modified carbon fiber, 50 parts of D-polylactic acid with a weight average molecular weight of 600000, 1.5 parts of vinyltrimethoxysilane, antioxidant 1680.5 parts of silicone powder, 0.1 part of silicone powder, and 2920.1 parts of light stabilizer; among them, the modified carbon fiber is obtained by sequentially oxidizing and grafting the carbon fiber, and the oxidation modification is to make the carbon fiber in 70wt% Treat in potassium permanganate solution at 80°C for 10 minutes, and for graft modification, treat the carbon fiber in 60 wt% sodium tetrafluoroborate aqueous solution at 70°C for 10 minutes.

[0057] The carbon fiber reinforced polylactic acid composite material can be prepared by the following method:

[0058] 1. Preparation of modified carbon fiber

[0059] Put the carbon fiber in 70wt% potassium permangan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com