High-temperature-resistant nylon PA66T material and preparation method thereof

A PA66, high-temperature-resistant technology, applied in the field of polymer synthesis, can solve problems such as insufficient salt formation process, lumpy nodes in material strips, etc., and achieve the effects of simple reaction steps, reduced environmental pressure, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

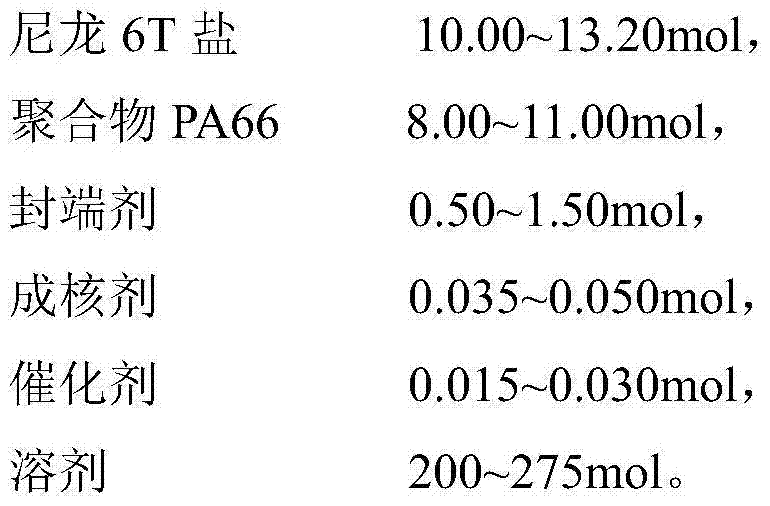

Method used

Image

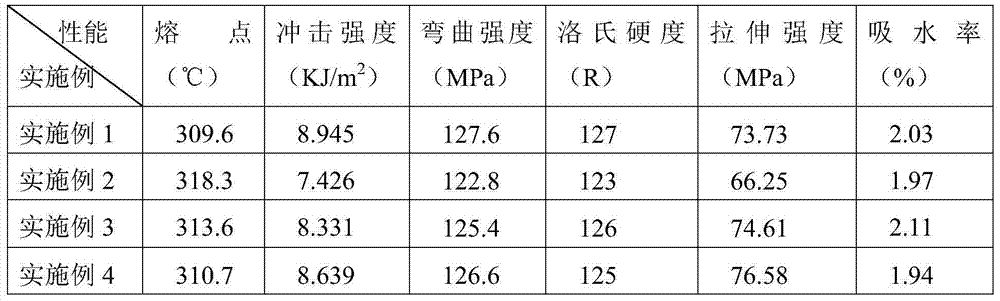

Examples

Embodiment 1

[0049]Weigh and dry nylon 6T salt 2823.4g (approximately 10mol), polymer PA662263.5g (approximately 10mol), end-capping agent benzoic acid 61.06g (approximately 0.5mol), catalyst sodium hypophosphite 1.2896g ( About 0.015mol) mix well and pour it into the high-pressure polymerization reactor, inject 3.60kg deionized water (200mol) and nucleating agent barium sulfate solution 101.34g (mass fraction is 8.06%, 0.035mol barium sulfate) under high pressure In the polymerization reactor, turn on the stirring device, fill it with nitrogen for vacuuming, and repeat 3 times to fully remove the air reserved in the reactor, and reserve 0.03MPa nitrogen as a protective gas.

[0050] The reactor is heated and heated by circulating heat transfer oil. At this time, the pressure in the reactor rises. When the pressure in the reactor reaches 1.5 MPa, the constant pressure of the reactor is maintained by releasing the moisture generated by the system reaction. Raise the temperature of the react...

Embodiment 2

[0053] Weigh and dry nylon 6T salt 3726.88g (approximately 13.2mol), polymer PA661991.88g (approximately 8.8mol), capping agent benzoic acid 183.18g (approximately 1.5mol), catalyst calcium hypophosphite 4.25 (0.025mol), mix well and pour it into a high-pressure polymerization reactor, inject 4.5kg of deionized water (250mol) and 143.8575g of nucleating agent talc powder solution (mass fraction is 8.16%, 0.045mol talc powder) in high pressure In the polymerization reactor, turn on the stirring device, fill it with nitrogen for vacuuming, and repeat 3 times to fully remove the air reserved in the reactor, and reserve 0.05MPa nitrogen as a protective gas.

[0054] The reactor is heated and heated by circulating heat transfer oil. At this time, the pressure inside the reactor rises. When the pressure in the reactor reaches 2.5MPa, the constant pressure of the reactor is realized by releasing the moisture generated by the system reaction. Continue through the circulation of heat tr...

Embodiment 3

[0057] Weigh and dry nylon 6T salt 3388.08g (approximately 12mol), polymer PA661810.8g (approximately 8.0mol), capping agent acetic acid 60.05g (approximately 0.4mol), catalyst potassium hypophosphite 2.0414g ( 0.020mol), mix well and pour it into the high-pressure polymerization reactor, inject 4.95kg deionized water (275mol) and nucleating agent silica solution 39.7354g (mass fraction is 7.56%, 0.05mol silica) in In the high-pressure polymerization reactor, the stirring device was turned on, the stirring speed was 60r / min, and nitrogen was filled for vacuuming, and repeated 3 times to fully remove the air reserved in the reactor, and reserve 0.10MPa nitrogen as a protective gas.

[0058] The reactor is heated and heated by circulating heat transfer oil. At this time, the pressure in the reactor rises. When the pressure in the reactor is 3.0 MPa, the constant pressure of the reactor is maintained by releasing the moisture generated by the system reaction. Raise the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com