Brush electroplating device and method for repairing part hole

A technology of brush plating and inner hole, which is applied in the direction of jewelry, etc., can solve the problems of uneven contact between the plating solution and the repaired part, unsatisfactory spraying method of the plating solution, and low efficiency of brush plating, so as to reduce the wear of the plating pen, Good processing effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

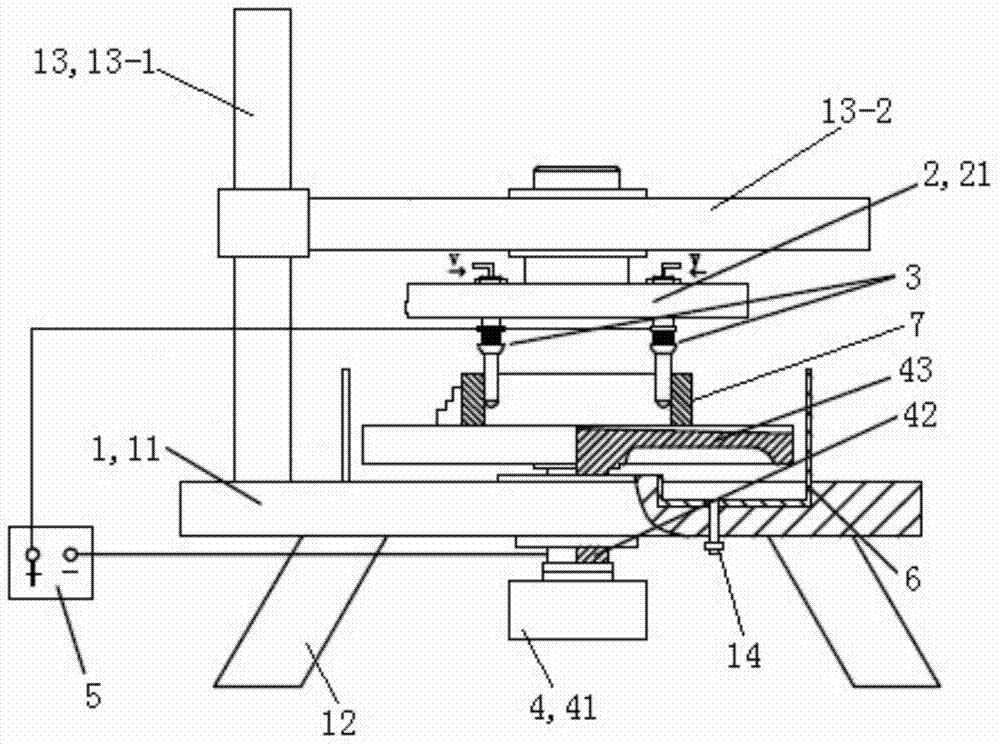

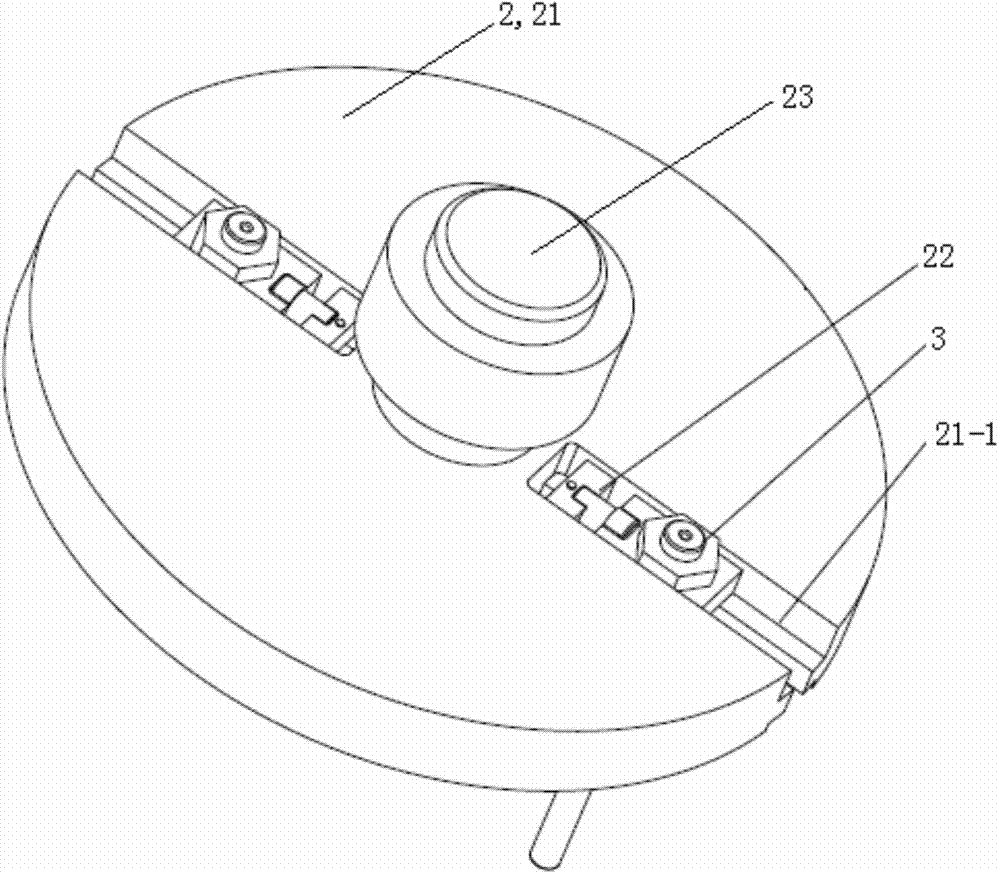

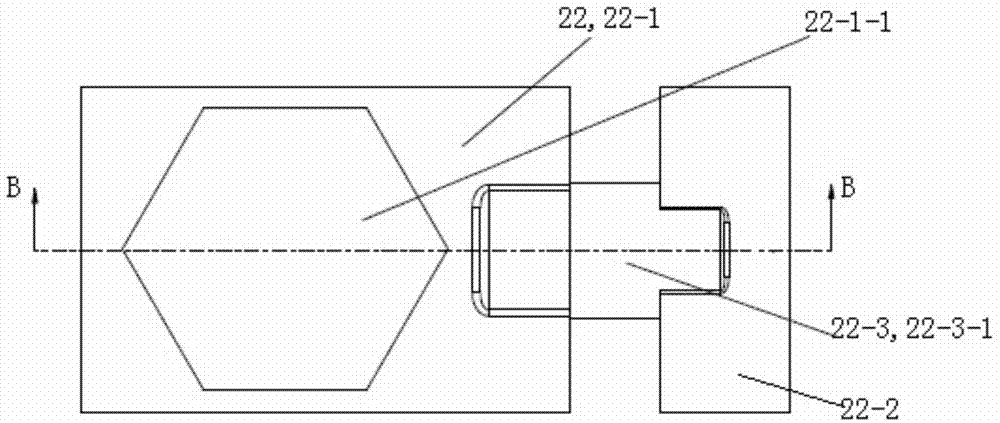

[0054] See figure 1 , The brush plating device for repairing inner holes of parts in this embodiment is mainly composed of a bracket 1, a plating pen clamping assembly 2, a plating pen 3, a driving assembly 4, a brush plating power supply 5 and a retaining ring 6.

[0055] The support 1 is mainly composed of a base 11 , supporting legs 12 , a lifting platform 13 , a liquid discharge nozzle 14 and an insulating block 15 . The base 11 is preferably a round platform in this embodiment. The upper part of the base 11 is provided with a ring-shaped waste liquid recovery tank that is concave downward from the upper end surface. The waste liquid recovery tank is provided with a drain nozzle installation hole that penetrates up and down. ; The middle position of the base 11 is provided with a shaft mounting hole that penetrates up and down; the support legs 12 are fixedly installed under the base 11, and are used to support the base 11 from the ground or tabletop. Lifting platform 13 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap