Manufacturing method for individual three-dimensional auricle guide plate

A technology of a guide plate and auricle, which is applied in the field of medical image processing, can solve the problems of lengthy, cumbersome operation steps, unfavorable for general doctors to grasp and popularize, etc., and achieves the effect of improving validity and increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of personalized three-dimensional auricle guide plate for patients with microtia

[0026] Firstly, import the DICOM format data obtained from CT scanning into Mimics software, use the midsagittal plane and guide plate positioning, and combine Mimics software to segment, extract, and reconstruct the image data to directly and quickly generate a 3D digital model of the auricle and guide plate on the affected side. Connect it with a 3D printer to create a three-dimensional solid model. Specifically include steps:

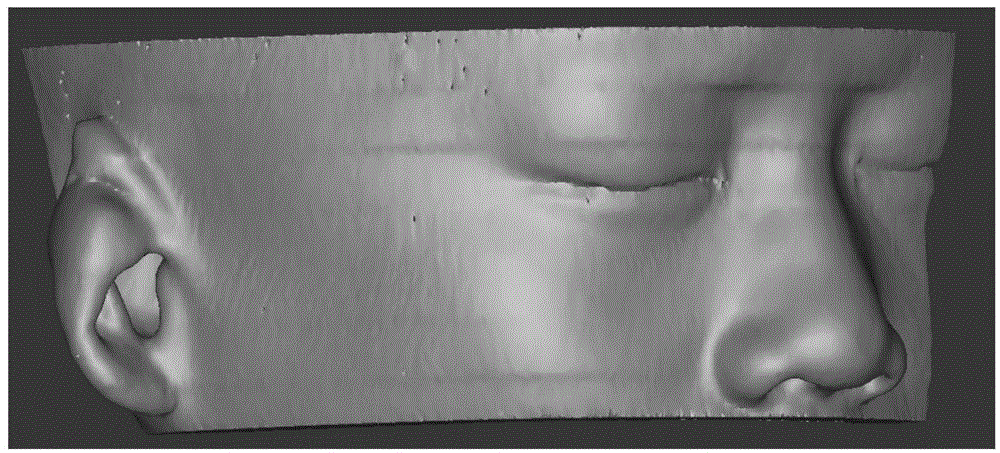

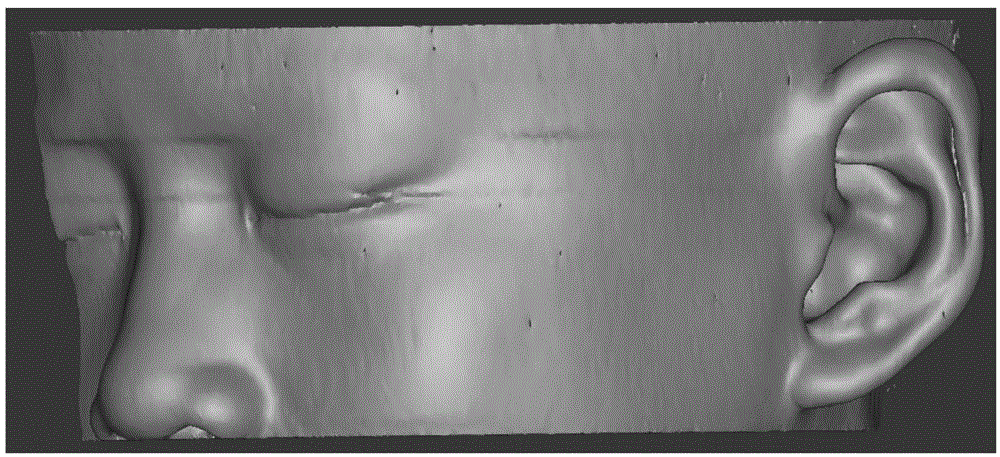

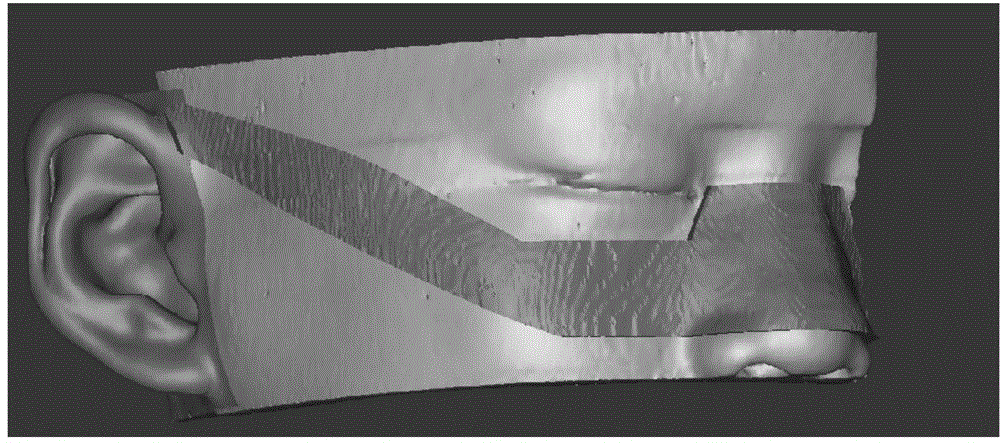

[0027] according to figure 1 , 2 As shown, import the DICOM format data obtained from the temporal bone CT scan of microtia patients into Mimics software, create a new Mask, select the threshold value range from -435 to 330, define the soft tissue, and extract the three-dimensional information of the auricle and face on the healthy side; make a cockscomb The mid-sagittal plane of the apex, the midpoint of the posterior edge of the foram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com