Diaphragm gluing machine for laminated battery pack and super-capacitor pack

A technology for supercapacitor packs and battery packs, applied in coatings, devices for coating liquids on surfaces, etc., can solve problems such as electrode short circuit, low work efficiency, and inability to achieve mass production of supercapacitors, and achieve uniform coating and speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

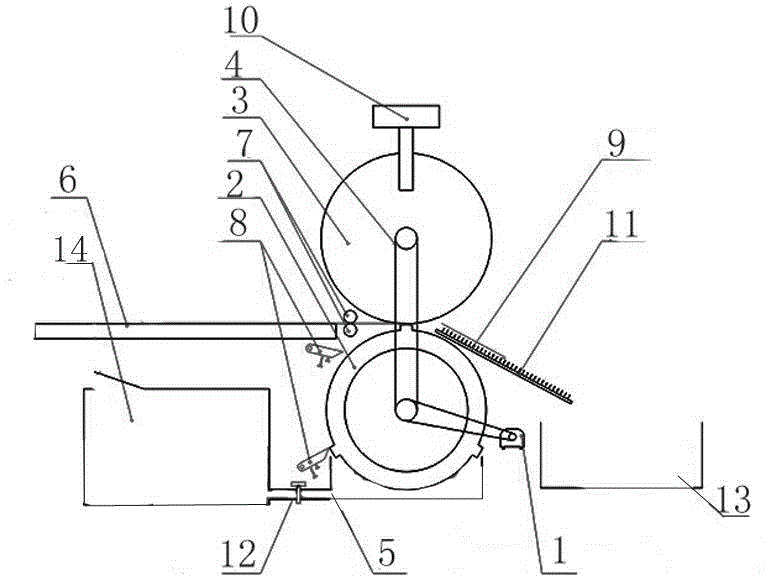

[0021] The present invention as figure 1 shown.

[0022] The laminated supercapacitor diaphragm gluing machine includes a driving motor 1, the driving motor 1 drives the sizing roller 2, the sizing roller 2 drives the rubber roller 3 through the pulley 4, and the sizing roller 2 is provided with a gluing groove 5, and the sizing roller 2 and One side of the rubber roller 3 is provided with a paper release platform 6, and the other side is provided with a receiving flat plate 11, and the tangent line between the sizing roller 2 and the rubber roller 3 corresponds to the paper discharge platform 6; the plane of the paper discharge platform 6 is connected to the sizing roller 2 and the rubber roller 3 Also be provided with paper feeding wheel 7 between.

[0023] Two scrapers 8 are arranged under the paper platform 6, and the scrapers 8 are divided into one upper and lower two corresponding to the sides of the sizing roller 2.

[0024] The receiving plate 11 is also provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com