Cold-resistant bamboo charcoal fiber fabric

A bamboo charcoal fiber and fabric technology, applied in the direction of layered products, chemical instruments and methods, metal layered products, etc., can solve the problems of poor rigidity and bending of fabrics, single shape, poor three-dimensional effect, etc., and achieve good thermal insulation effect and fabric Simple structure, anti-cold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

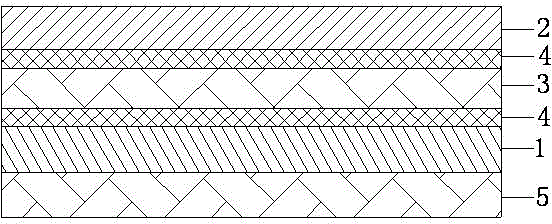

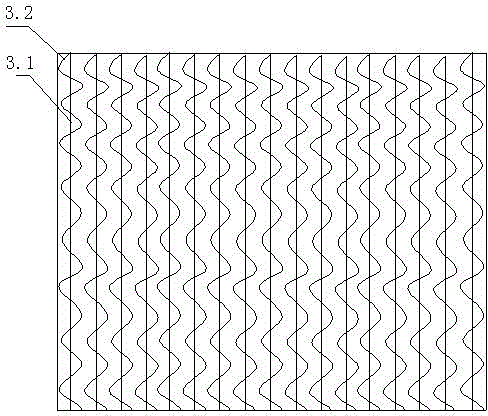

[0013] see figure 1 and figure 2 , the present invention relates to a kind of anti-cold bamboo charcoal fiber fabric, it comprises bamboo charcoal fiber 1, described bamboo charcoal fiber 1 is covered with one layer of non-woven fabric 2 above, is covered with one layer of base layer 5 below, described non-woven fabric 2 and bamboo charcoal fiber 1 An antistatic layer 3 is also provided between them, and the antistatic layer 3 is made of cored silk fibers, which include yarns 3.1 and metal wires 3.2, and the metal wires 3.2 are wound on the yarns 3.1, so that Between the above-mentioned bamboo charcoal fiber 1 and the antistatic layer 3 and between the antistatic layer 3 and the nonwoven fabric 2, all bond by glue layer 4.

[0014] The bamboo charcoal fiber and non-woven fabric in this kind of cold-resistant bamboo charcoal fiber fabric have good air permeability, and the yarn 3.1 and the metal wire 3.2 form a cored yarn to form an antistatic layer, which makes the fabric ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com