Pulverized coal storing and supplying system

A pulverized coal and monitoring system technology, which is applied in the direction of block/powder supply/distribution, fuel supply, and fuel supply adjustment, can solve the problems of boiler explosion, poor feeding, small volume, etc., to avoid explosion, The effect of improving accuracy and reducing the impact of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

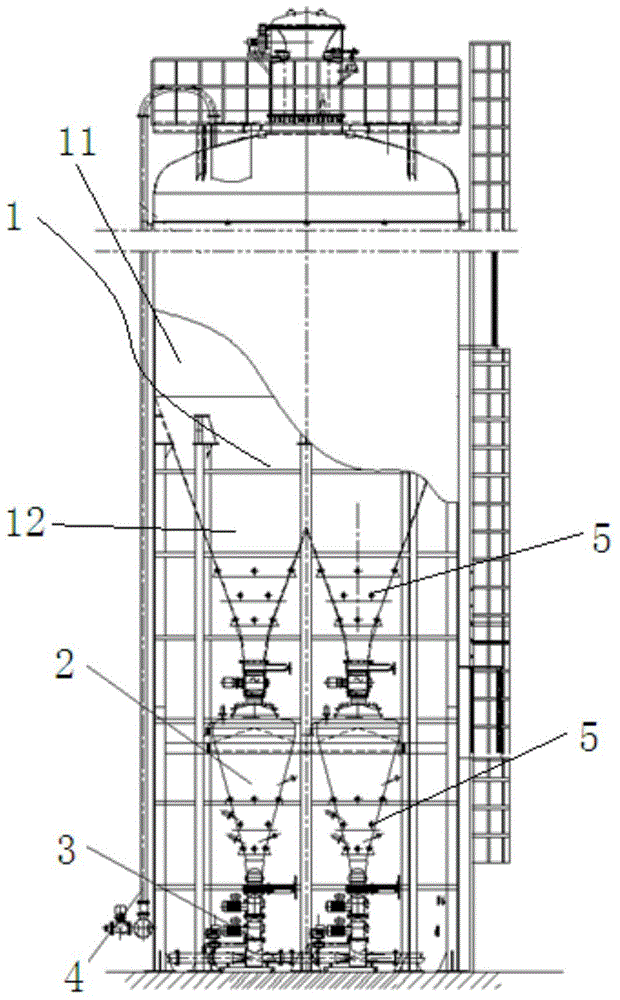

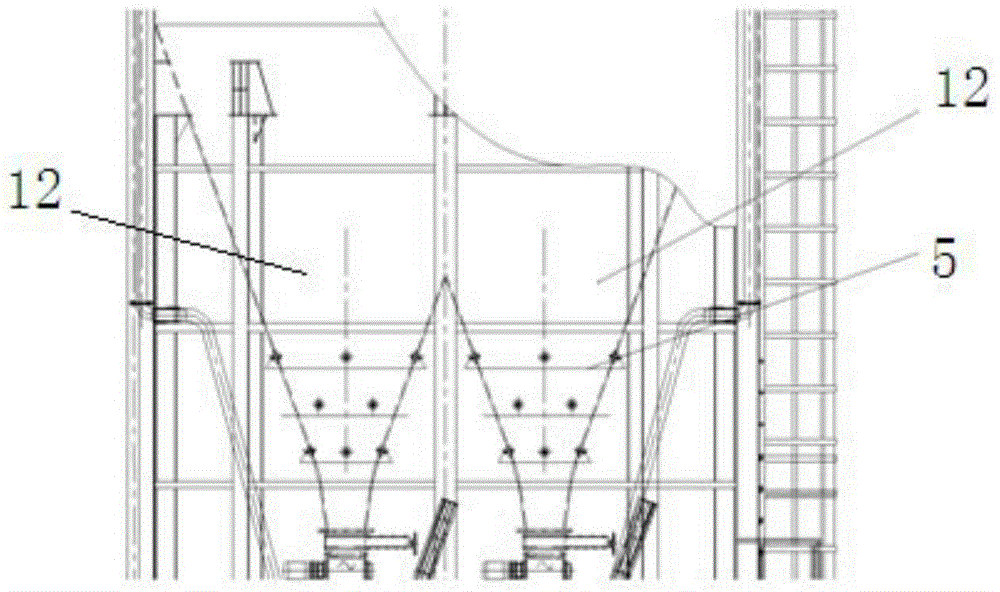

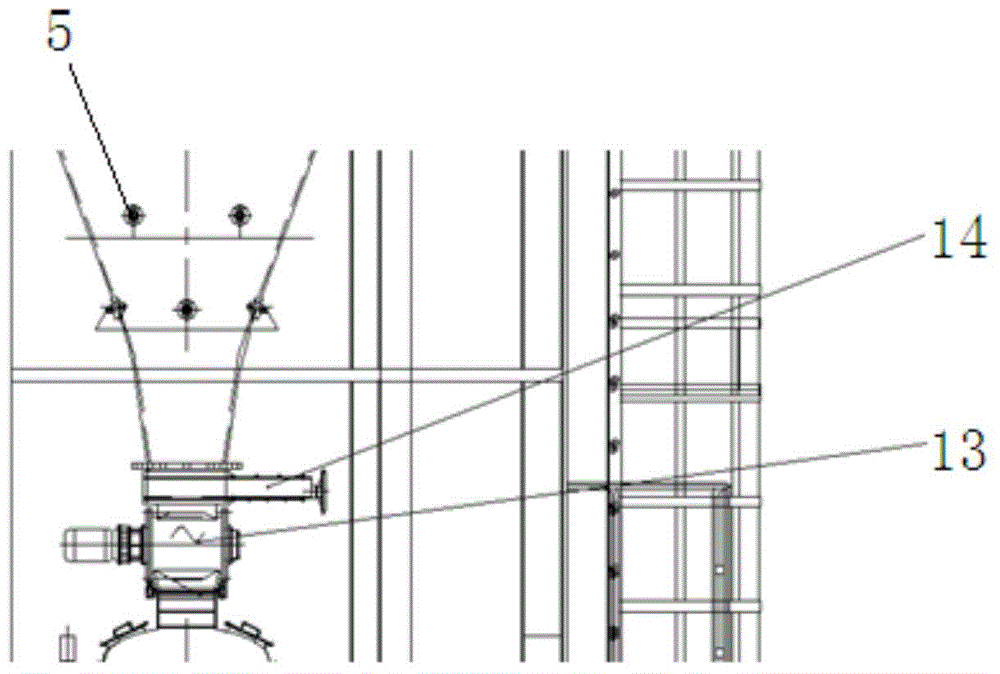

[0024] like figure 1 As shown, the pulverized coal storage and supply system of the present invention includes a large powder bin 1, more than two buffer bins 2, more than two feeders 3, an upper powder pipe 4, several fluidization devices 5 and a monitoring system , the number of fluidization devices 5 is not limited, and in actual application, it is determined according to needs; the large powder silo 1 includes a cylindrical silo 11 and more than two conical silo 12, and the top of the cylindrical silo 11 is connected with a powder pipe 4, the bottom of the cylindrical bin 11 is fixedly connected to the top of each conical bin 12, and the bottom of each conical bin 12 is connected to each buffer bin 2 through a soft connection (not shown in the figure). On the top, the bottom of each buffer bin 2 is connected to each feeder 3 through a soft connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com