Coal slime drying device in coal washery utilizing waste heat of brick-firing tunnel kiln

A technology of tunnel kiln and coal washing plant, applied in the field of coal washing device, can solve the problem of consuming large heat energy, etc., and achieve the effects of energy saving, low equipment investment cost, and easy popularization and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

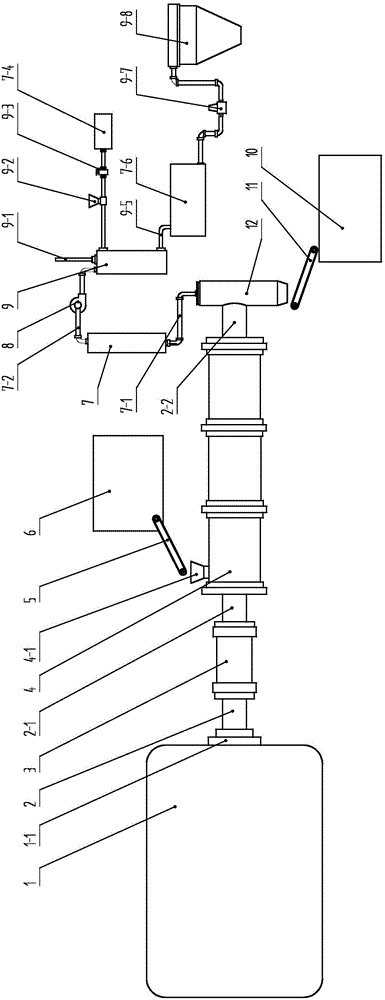

[0020] A device for drying coal slime in a coal washing plant by using waste heat from a brick-fired tunnel kiln, characterized in that the slime drying device includes an induced draft fan I3, a drum dryer 4, a coal slime bin to be dried 6, and a feeding belt conveyor 5 , screw feeder 12, discharge belt conveyor 11 and coal slime finished product bin 10. The inlet of the induced draft fan I3 is connected to the tunnel kiln cooling section 1-2 of the brick firing tunnel kiln 1 through the air pipe I2; the outlet of the induced draft fan I3 is connected to the front end of the drum dryer 4 through the air pipe II2-1. The front end of the drum dryer 4 is provided with a feeding hopper 4-1; the coal slime to be dried in the slime bin 6 enters the drum dryer 4 through the feeding belt conveyor 5 and the feeding hopper 4-1. The rear end of the tumble dryer 4 is connected to the screw feeder 12 through the gas delivery pipe III2-2. The screw feeder 12 sends the dried finished coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com