Method for diagnosing internal damage of cereal grains based on micro-CT (computed tomography) technology

A CT technology, a grain technology, is applied in the field of diagnosing internal grain damage based on micro-CT technology, which can solve problems such as heavy workload, restricted application, and inability to truly and comprehensively characterize microstructure feature information, so as to improve accuracy and preserve primitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following rice is taken as an example in conjunction with the accompanying drawings to further illustrate the present invention, but the protection scope of the present invention is not limited thereto.

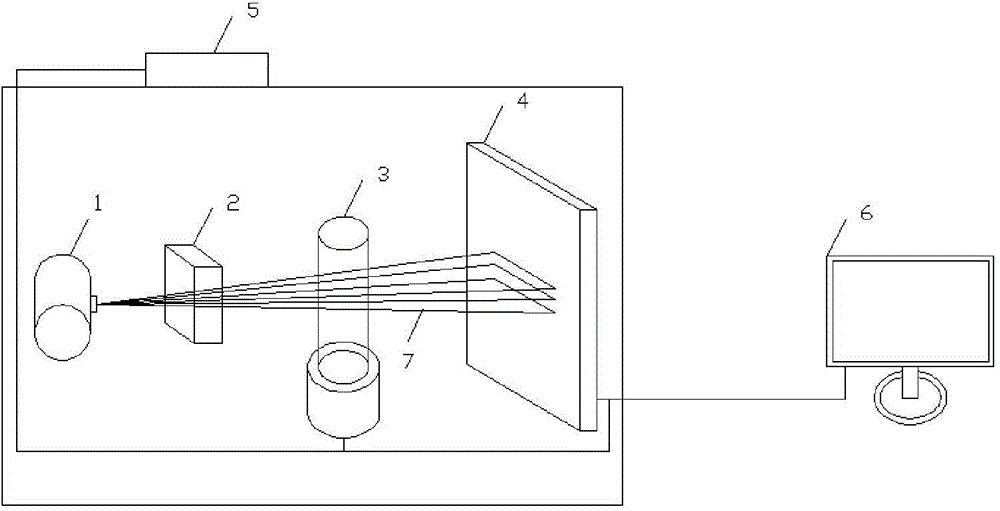

[0029] The micro-focus CT equipment that adopts in the specific embodiment of the present invention refers to figure 1 . use figure 1 The shown micro-focus CT equipment collects tomographic images of rice grains, which includes an X-ray tube 1 with a maximum voltage of 90 kvp and a maximum current of 200 μA. The rice grains are placed in a sample tube 3 with a diameter of 9 mm and a detector 4. The resolution is 4 μm, and the X-ray energy spectrum after passing through the collimator and filter 2 can be collected and transmitted to the image workstation 6, and the automatic sample changer 5 can place the sample tubes into the cabin one by one by itself. The collimator, filter 2, sample tube 3 and detector 4 are integrated in a closed steel structure cabin.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com