Wafer packaging structure, chip packaging structure and packaging method thereof

A wafer packaging and wafer technology, applied in radiation control devices, electrical components, electrical solid devices, etc., can solve the problems of affecting the etching process, bulging, and generating flyers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

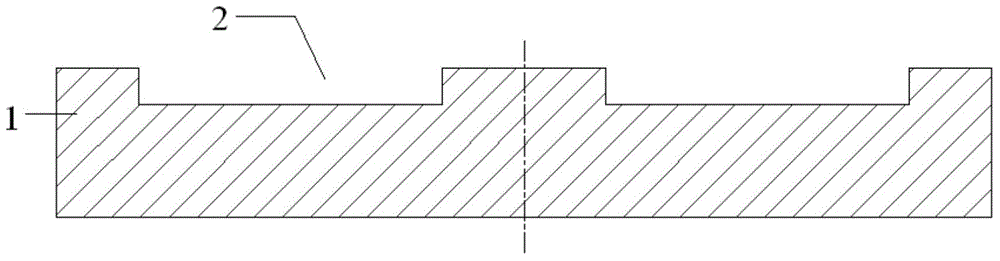

[0055] see Figure 11 , Figure 12 , Figure 13 with Figure 14 , a wafer packaging structure, including a large base with several base units 1 and a wafer with several image sensor chip units 9 .

[0056] The large substrate has a first surface and a second surface opposite to it. At least one first groove 2 is formed in the middle of the first surface of each base unit, and at least one exhaust gas is formed around the first groove of the middle base unit. Groove 4, the exhaust groove communicates with the first groove of the peripheral adjacent base unit, at least one exhaust groove is formed on the periphery of the first groove of the base unit on the edge, and the exhaust groove extends to the edge of the substrate Connect with the external environment. better, see Figure 12 , the four sides of the first groove 2 of each base unit are respectively provided with an exhaust groove 4, and the four exhaust grooves all extend to the outside of the edge of the base unit, ...

Embodiment 2

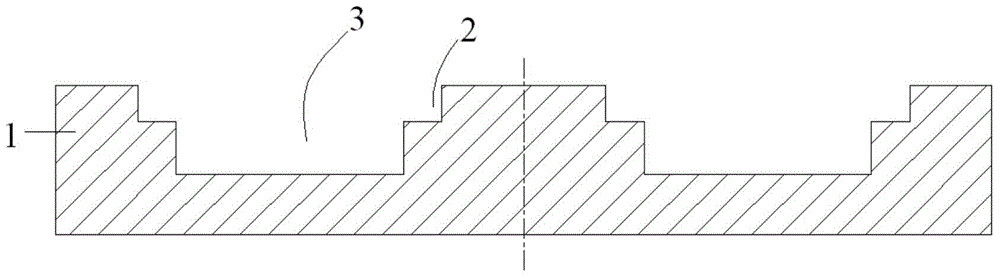

[0080] see Figure 16 with Figure 17 , a wafer package structure, comprising a large base with several base units 1, the large base has a first surface and a second surface opposite to it, at least one first groove is formed in the middle of the first surface of each base unit 2. At least one exhaust groove 4 is formed on the periphery of the first groove of the middle base unit. There is at least one exhaust groove, and the exhaust groove extends to the edge of the base to communicate with the external environment. Preferably, the four sides of the first groove 2 of each base unit are respectively provided with an exhaust groove 4, and the four exhaust grooves all extend to the outside of the edge of the base unit, that is, between the horizontal plane below the first surface of the base and The external environment is connected.

[0081] The bottom of the first groove is provided with a functional chip 12, the functional chip has a first surface and a second surface oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com