Self-walking device and rotary cultivator with same

A self-propelled device and traveling wheel technology, applied in the field of rotary tillers, can solve the problems of low traction force, low technology content, increased chassis frame load, etc., and achieve the effects of reducing belt slippage, optimizing transmission mode, and reducing power loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

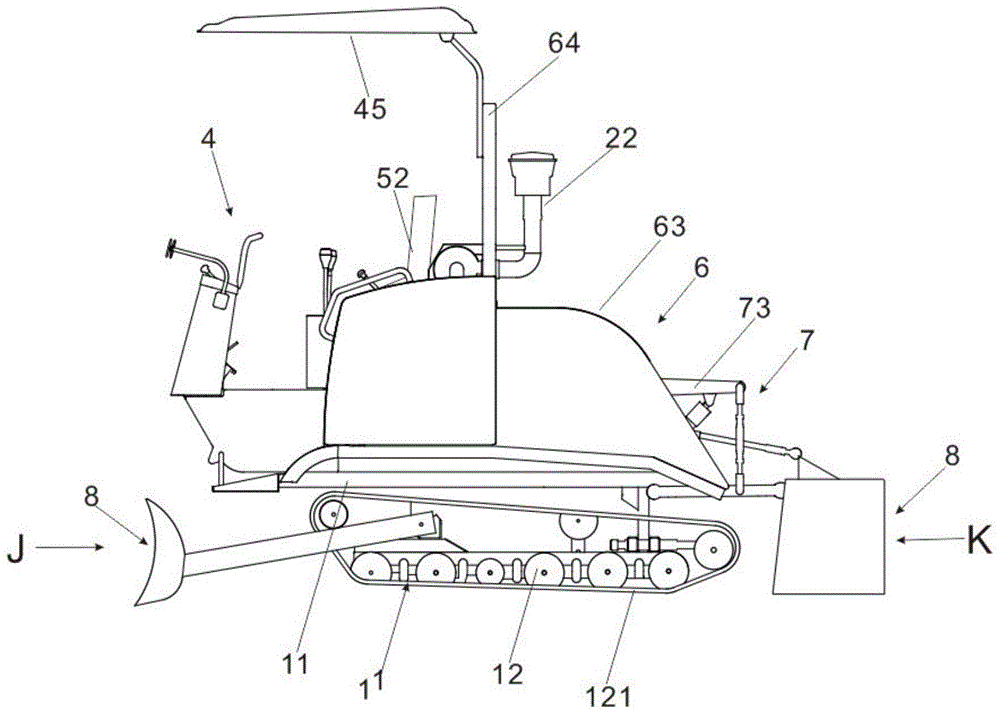

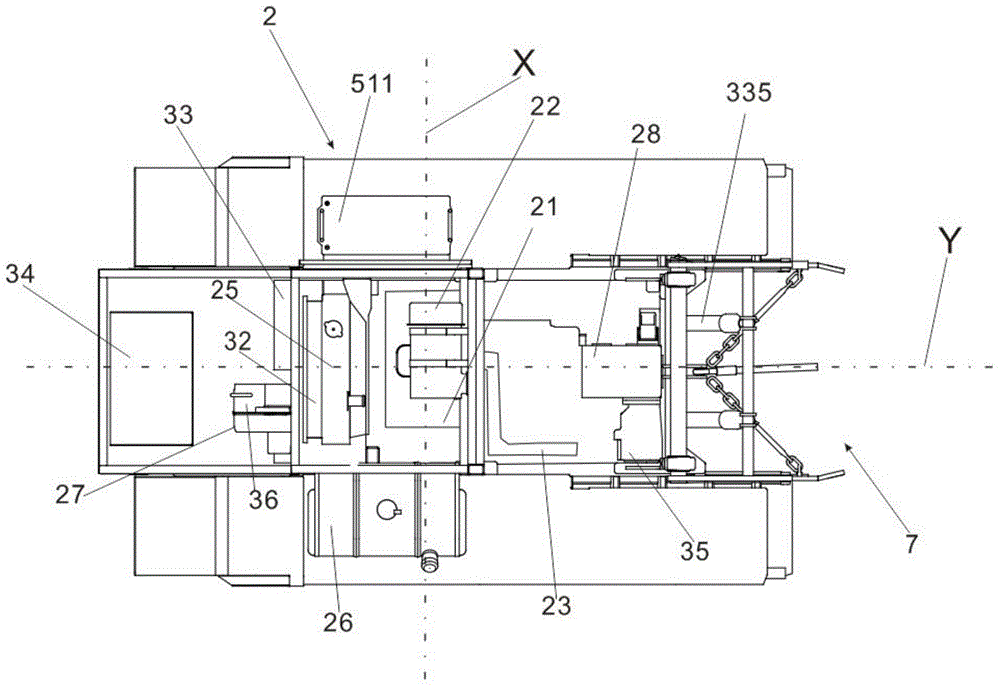

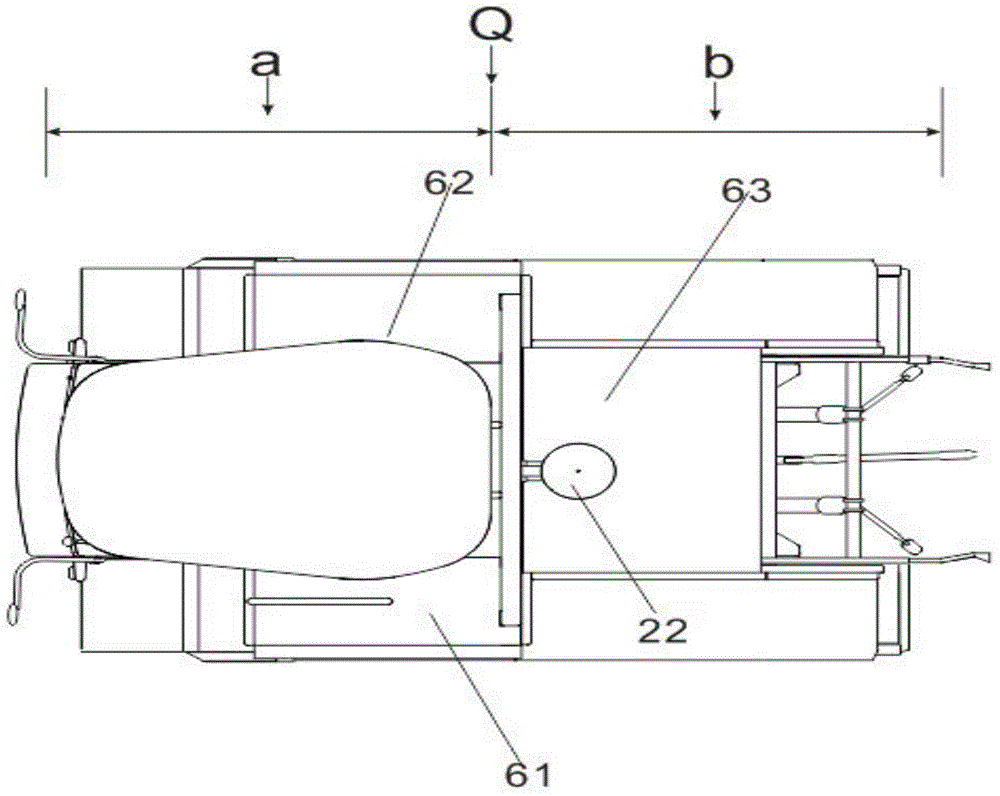

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of self-propelled device comprises walking system 1, power system 2, control system 4, suspension system 7, supporting system 8, and walking system is made up of chassis frame 11 and walking wheel train 12, and walking wheel train 12 is installed on On the support below the chassis frame 11, the power system 2 and the steering system 4 are installed above the chassis frame, and the suspension system 7 is installed at the rear of the chassis frame. Power system 2 comprises engine 21, power output transmission box 28, hydraulic pump 35, hydraulic motor 36, travel gearbox 27, engine 21 links to each other with power output transmission box 28, power output transmission box 28 is connected with hydraulic pump 35 and hydraulic motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com