T-profile assembly tool

A technology for assembling tooling and profiles, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of low welding efficiency, unreliable welding quality, increased safety hazards, etc., and achieve low dependence on welders and stable product quality. Reliable, labor-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

[0067] The invention provides a T-shaped bar assembling tool, which can be used in a shipyard to assemble various types of marine T-shaped bars.

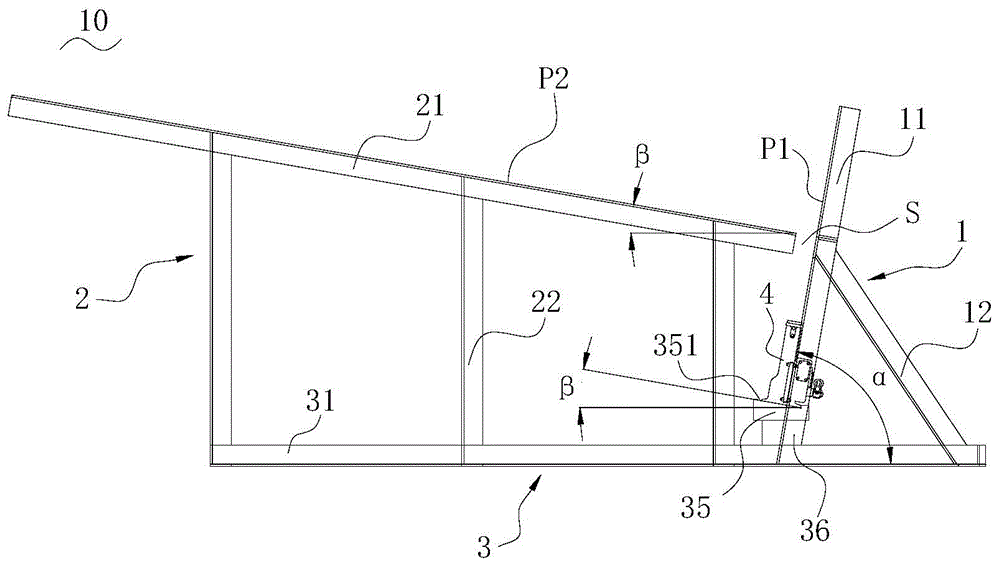

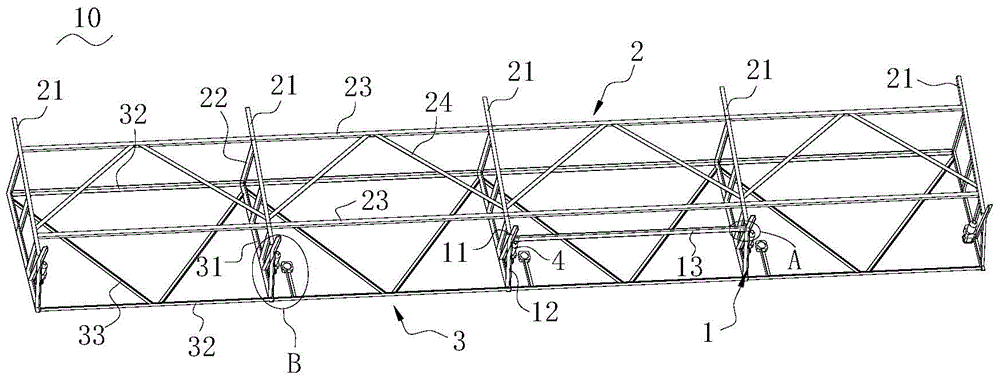

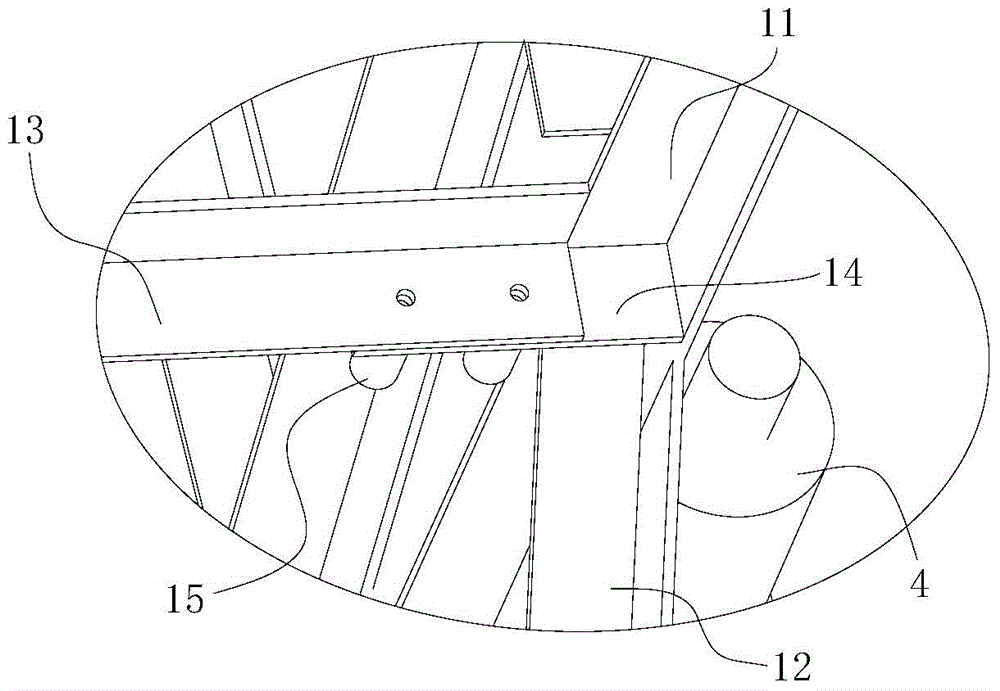

[0068] refer to figure 1 and figure 2 , As a preferred embodiment, the T-shaped bar assembly tool 10 includes a chassis 3 , a panel tire frame 1 , a web tire frame 2 and a lifting device 4 . The underframe 3 serves as a support for the entire tooling 10, so that the tooling 10 can be placed on the ground, and facilitates the movement of the tooling 10. The panel frame 1 is used to carry the panel of the T p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com