Surface cold processing device for porcelain polished tiles

A technology of polishing bricks and cold working, which is applied to grinding drive devices, metal processing equipment, grinding/polishing equipment, etc. The effect of reducing the equipment footprint and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

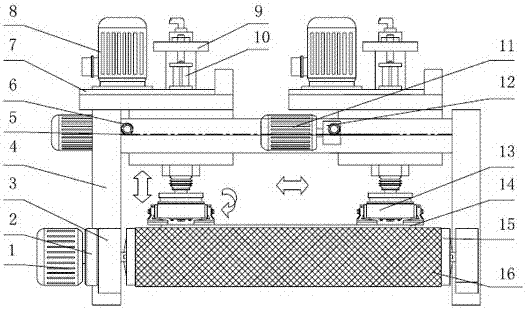

[0061] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

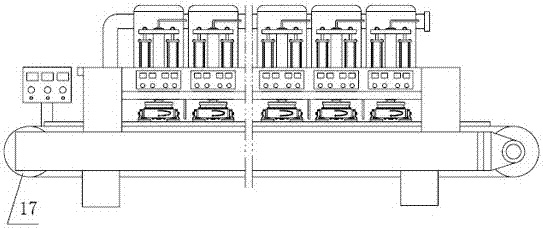

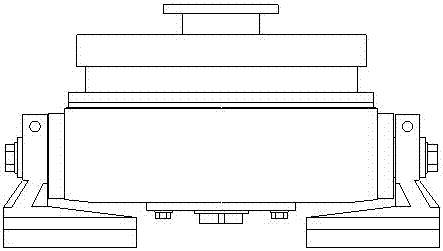

[0062] like Figure 5 , 6 As shown, the present invention provides a kind of porcelain polished tile surface cold processing device, comprises frame 3, driving device 1 and grinding head device 2, and described frame 3 is provided with crossbeam fixing system 4, and described crossbeam fixing system 4 Fixedly connected with the frame 3, the driving device 1 and the grinding head device 2 are both installed on the beam fixing system 4.

[0063] The invention adopts the processing method of fixing the beam, changes the existing mode of beam swing, simplifies the structure of the polishing machine, reduces the equipment footprint, and no longer needs equipment such as a beam swing motor and a beam swing gearbox. Moreover, it effectively avoids the pot-shaped shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com