Single-plate unmanned operation rotary cutter

A technology of rotary cutting machine and veneer, which is applied in the manufacture of veneer, wood processing equipment, manufacturing tools, etc. It can solve the problems of low production efficiency and high labor intensity of workers, achieve convenient production, simple structure, and change manual production. mode effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

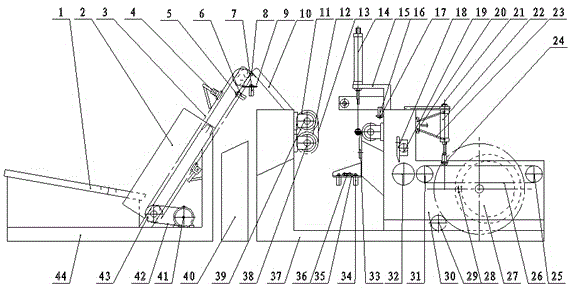

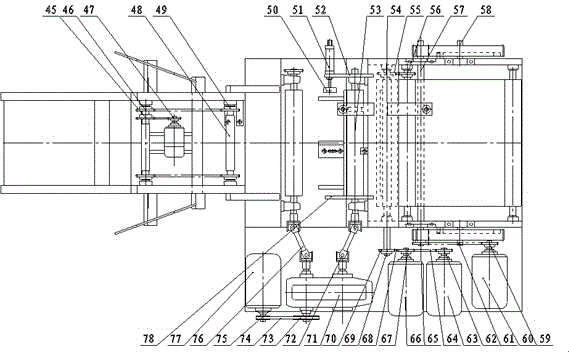

[0016] Example 1, see figure 1 , figure 2 , processed and welded to make a feeding frame 44, a rotary cutting frame 37, and a movable knife table 30, all gears, sprockets, chains, pneumatic components, electrical components, etc. are purchased in the market; the programmable control box 40 preset programs, all rollers , sprocket shaft, and both ends of the gear shaft are equipped with seated bearings;

[0017] Loading machine part: install the storage rack 1, the guide plate 2, the first motor 41, the first sprocket shaft 43, the second sprocket shaft 48, the first photoelectric bracket 5, and the second photoelectric bracket on the loading frame 44 9; install the fifth sprocket 47 on the first motor 41; install the third sprocket 45 and the fourth sprocket 46 on the first sprocket shaft 43; install between the fifth sprocket 47 and the third sprocket 45 The third chain 42; the sixth sprocket 49 is installed on the second sprocket shaft 48; the first chain 3 is installed be...

Embodiment 2

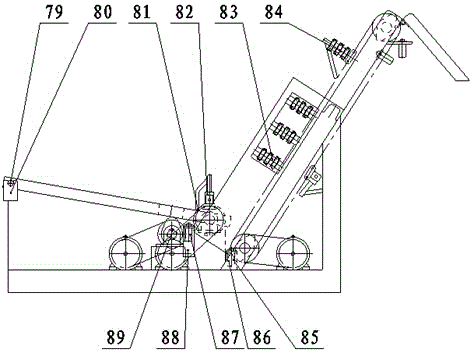

[0020] Example 2, see image 3 , 4 , with embodiment 1, the difference is that the storage rack 1, the guide plate 2, the first motor 41, the first sprocket shaft 43, the second sprocket shaft 48, the first photoelectric support are installed on the feeding frame 44 5. The second photoelectric support 9, the storage rack support 80, the fifth photoelectric support 86, the sixth photoelectric support 88, the sixth motor 90, the seventh motor 92, the third sprocket shaft 91, and the fourth sprocket shaft 97; The fifth sprocket 47 is installed on a motor 41; the third sprocket 45 and the fourth sprocket 46 are installed on the first sprocket shaft 43; the third chain 42 is installed between the fifth sprocket 47 and the third sprocket 45 Install the sixth sprocket 49 on the second sprocket shaft 48; install the first chain 3 link between the fourth sprocket 46 and the sixth sprocket 49; install the first driving lever 4 on the first chain 3, The second roller 84 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com