EVA (ethylene-vinyl acetate) adhesive film recovery granulator

A granulator and plastic film technology, applied in the field of EVA plastic film recycling granulator, can solve the problems of incomplete exhaust and insufficient mixing, and achieve the effect of improving heat exchange efficiency and improving melting and mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

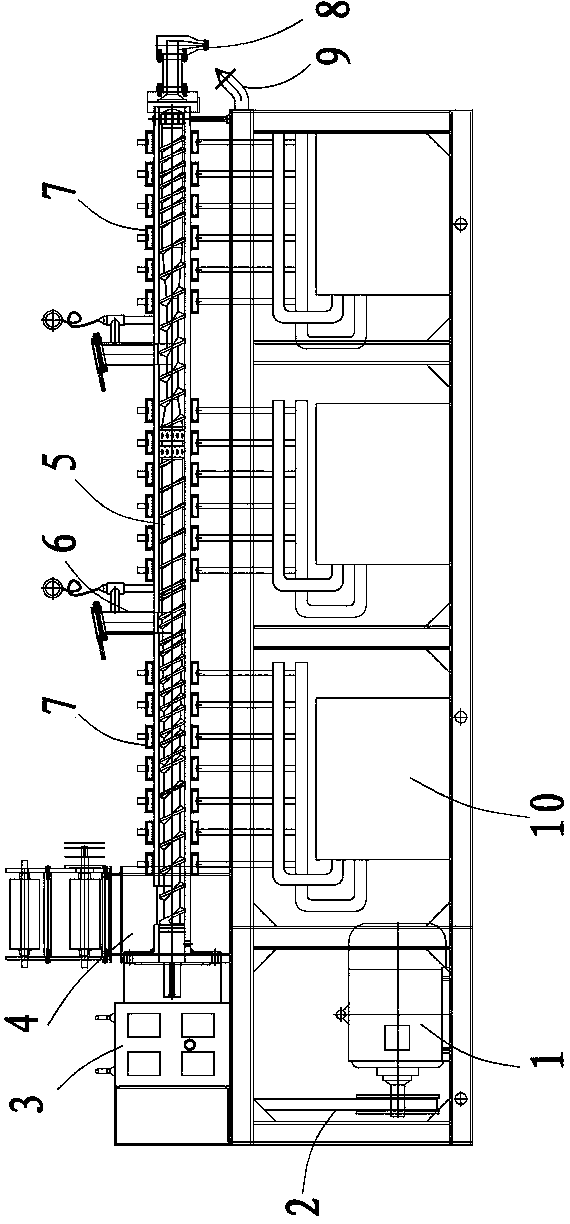

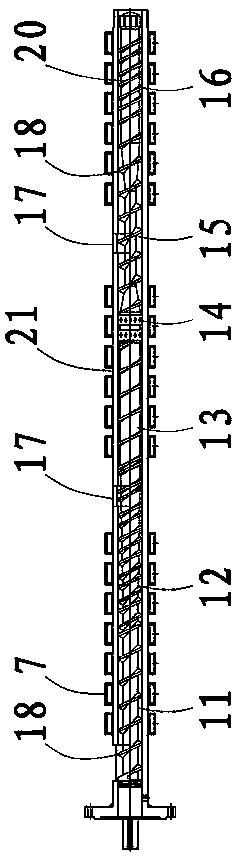

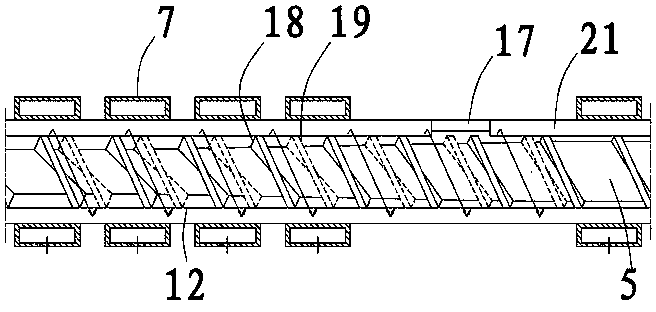

[0022] Embodiment: a kind of EVA film recycling granulator, as figure 1 shown. The frame top of this device is provided with horizontal screw rod 5, and the frame bottom of screw rod head end is provided with motor 1, and motor 1 drives screw rod 5 to rotate by belt 2, reduction box 3 successively. The head end of the screw is provided with a feeding port 4, and the end is provided with an extrusion port 8, and the extrusion port discharges material downwards, and a cooling nozzle 9 is arranged on the frame facing the outer wall of the extrusion port for cooling by spraying air. A screw sleeve 21 is arranged on the outside of the screw, and a water jacket 7 is coiled outside the screw sleeve. There is a heating wire for auxiliary heating. The water jacket 7 on the outside of the screw sleeve is divided into three sections along the conveying direction, and each section of the water jacket corresponds to a water tank, and each section of the water jacket has a common water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com