An intelligent temperature and humidity control steamer

A technology of temperature control, humidity control, and steaming machine, which is applied to printing presses, rotary printing machines, lithographic rotary printing machines, etc. It can solve the problems of inability to achieve fast color fixation, uneven saturated steam, environmental pollution, etc., and achieve molding Good color fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the invention is not limited by the embodiments.

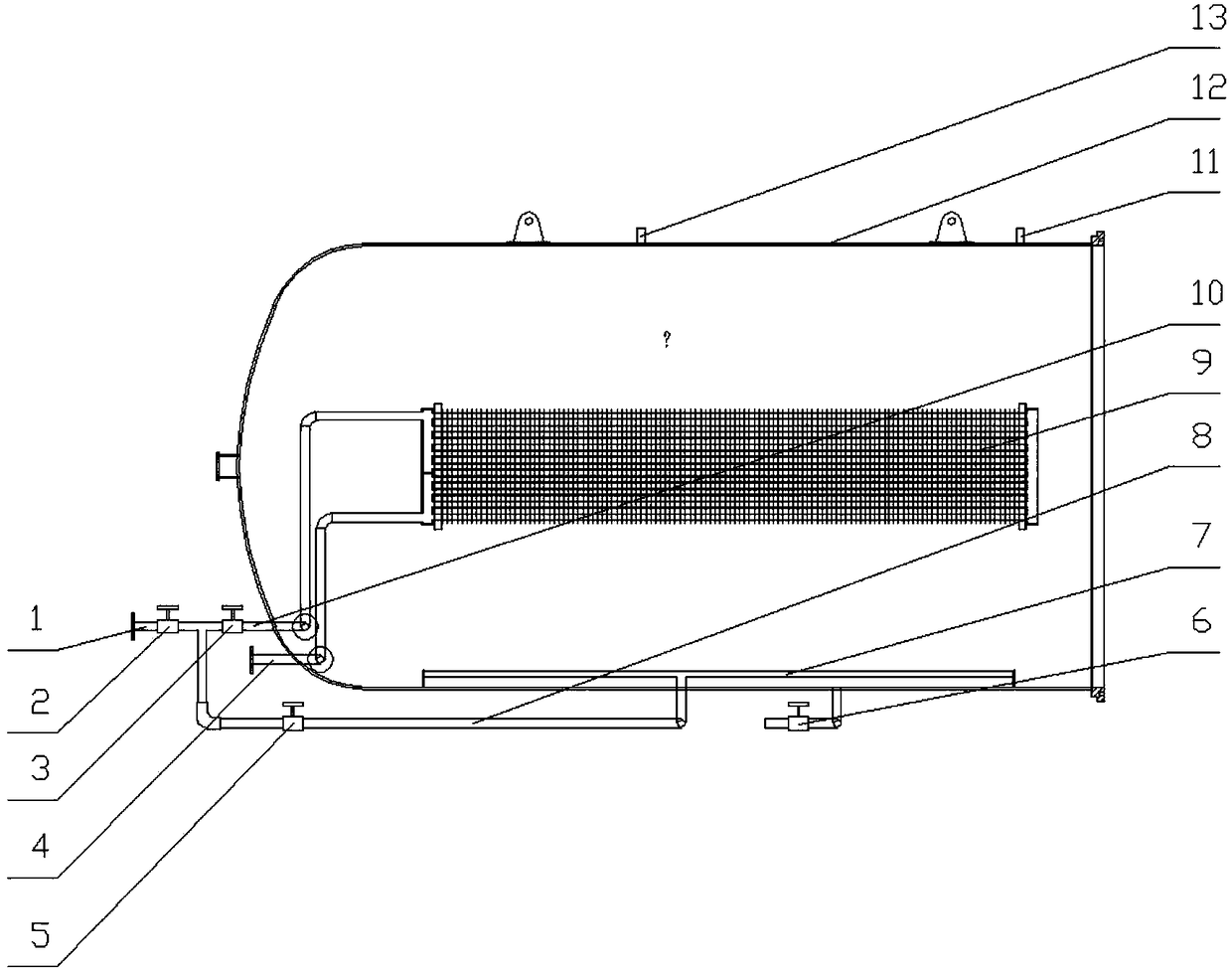

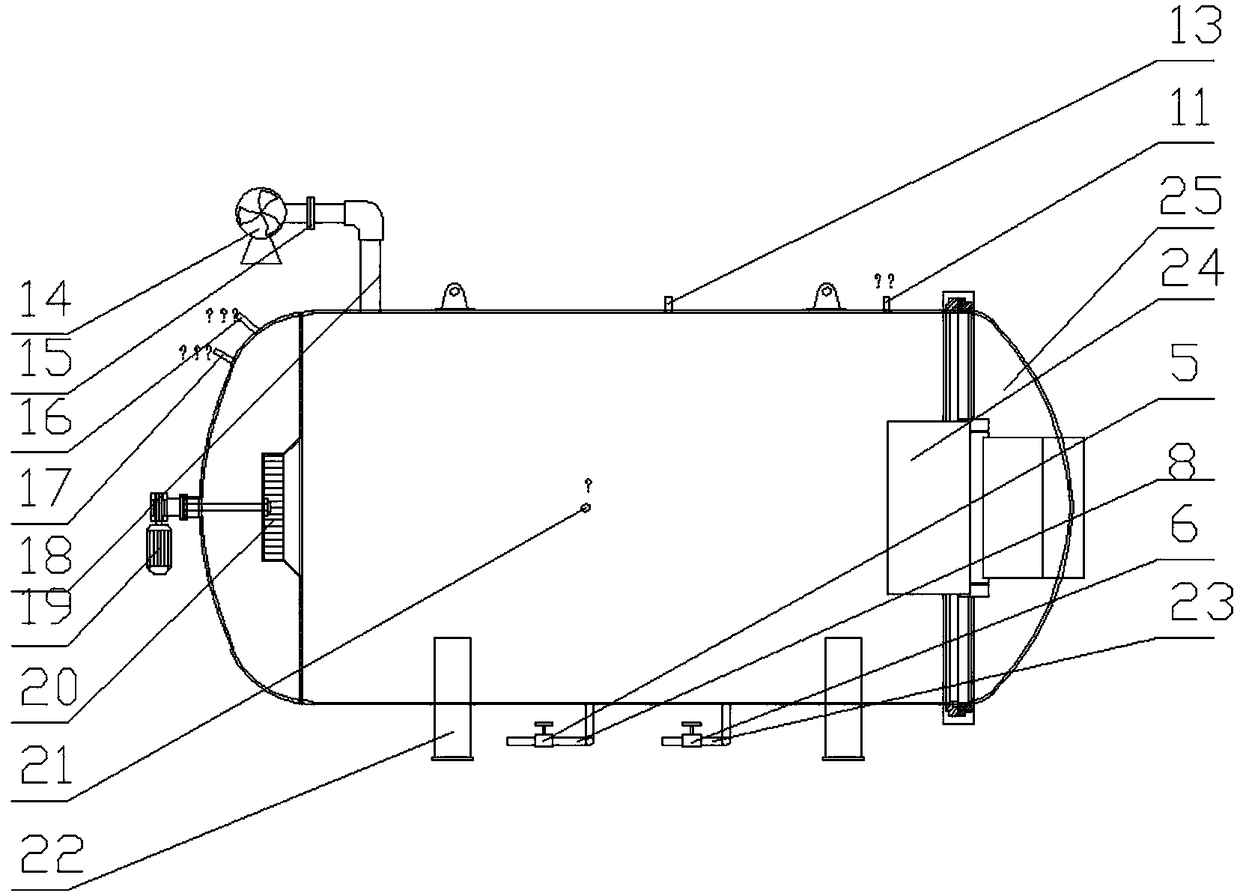

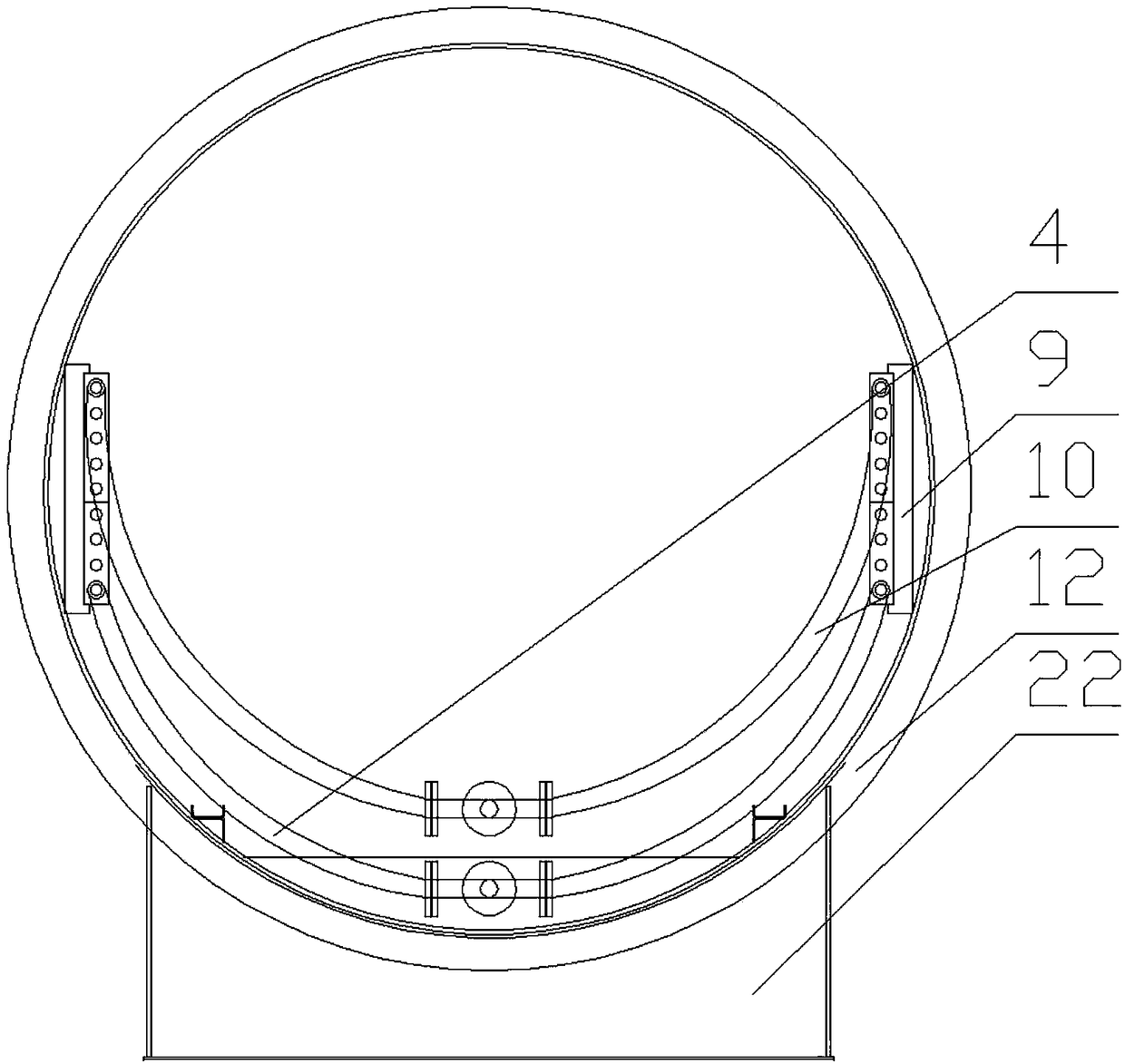

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, an intelligent temperature and humidity control steamer is mainly composed of a body 12, a bracket 22, a hatch 25 and a hinge 24. The body 12 can be made into a barrel or a cuboid, and the bracket 22 is fixed on the bottom of the body 12 by welding. , to support the body 12. A hatch 25 is installed on one side of the body 12 , and the hatch 25 and the body 12 form a movable link through a hinge 24 .

[0029] Located on the rear side outside the body 12, there is a steam inlet main pipe 1, on which the steam inlet main pipe 1 is equipped with a steam inlet main pipe pneumatic valve 2. Both sides of the inner wall of the body 12 are symmetrically equipped with cooling fins 9, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com