Air-drying automobile-used water-based finishing coat and water-based intermediate coat, as well as preparation method and use methods thereof

A water-based topcoat, self-drying technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of uneven gloss, easy sagging, pigment drift, etc., achieve uniform particle size distribution, good compatibility, The effect of low molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

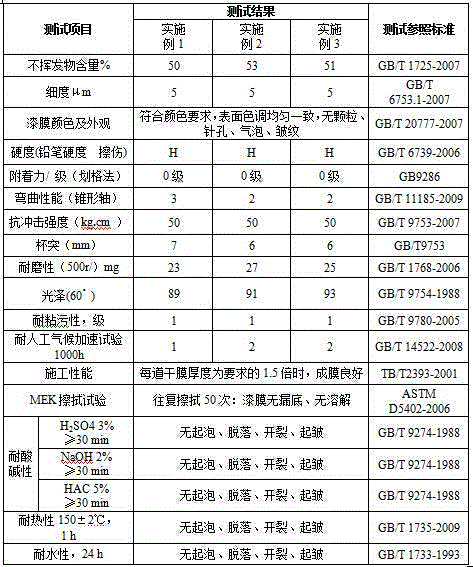

Examples

Embodiment 1

[0083] (a) Add 10 parts of water-based castor oil modified alkyd resin, 20 parts of water-based acrylic resin, 0.1 part of defoamer, 0.5 part of dispersant, 0.1 part of wetting agent and 2 parts of deionized water into the stirring tank in sequence, Under the condition of 400~800r / min rotating speed, stir for 5~10 minutes.

[0084] (b) Add 0.1 part of pH regulator, adjust the pH to 7.0~9.0, and stir for 10~15 minutes at 400~800r / min.

[0085] (c) Add 2 parts of pigments, 0.1 parts of preservatives, 0.1 parts of rheology modifiers, 2 parts of film-forming aids, and 0.2 parts of thickeners in sequence, and stir and disperse for 20~30 minutes at a speed of 600~1000r / min. minute.

[0086] (d) Add 0.1 parts of leveling agent, and stir and disperse for 5 to 10 minutes at a speed of 400 to 600 r / min.

[0087] (e) Finally, add 3 parts of deionized water to adjust the viscosity, and stir for 10-15 minutes at a speed of 400-600r / min to obtain a water-based two-component polyurethane s...

Embodiment 2

[0091] (a) Add 30 parts of water-based castor oil modified alkyd resin, 50 parts of water-based acrylic resin, 1 part of defoamer, 5 parts of dispersant, 1 part of wetting agent and 3 parts of deionized water into the stirring tank, Under the condition of 400~800r / min rotating speed, stir for 5~10 minutes.

[0092](b) Add 0.5 parts of pH regulator, adjust the pH to 7.0~9.0, and stir for 10~15 minutes at 400~800r / min.

[0093] (c) Add 25 parts of pigments, 0.2 parts of preservatives, 1 part of rheology modifier, 15 parts of film-forming aids, and 1 part of thickener in sequence, and stir and disperse for 20-30 minute.

[0094] (d) Add 0.5 parts of leveling agent, and stir and disperse for 5 to 10 minutes at a speed of 400 to 600 r / min.

[0095] (e) Finally, add 7 parts of deionized water to adjust the viscosity, and stir for 10-15 minutes at a speed of 400-600r / min to obtain a water-based two-component polyurethane solid color topcoat.

[0096] Then provide silicon-modified ...

Embodiment 3

[0099] (a) Add 20 parts of water-based castor oil modified alkyd resin, 35 parts of water-based acrylic resin, 0.5 part of defoamer, 3 parts of dispersant, 0.6 part of wetting agent and 3 parts of deionized water into the stirring tank in sequence, Under the condition of 400~800r / min rotating speed, stir for 5~10 minutes.

[0100] (b) Add 0.3 parts of pH regulator, adjust the pH to 7.0~9.0, and stir for 10~15 minutes at 400~800r / min.

[0101] (c) Add 14 parts of pigments, 0.15 parts of preservatives, 0.5 parts of rheology modifiers, 8 parts of film-forming aids, and 0.6 parts of thickeners in sequence, and stir and disperse for 20~30 minute.

[0102] (d) Add 0.3 parts of leveling agent, and stir and disperse for 5 to 10 minutes at a speed of 400 to 600 r / min.

[0103] (e) Finally, add 4 parts of deionized water to adjust the viscosity, and stir for 10-15 minutes at a speed of 400-600r / min to obtain a water-based two-component polyurethane solid color topcoat.

[0104] Then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com