Epoxy grout

A technology of epoxy mastic and epoxy resin, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of falling off, easy cracking of anti-corrosion and curing materials, poor cold and heat resistance, etc., and achieve high temperature difference high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

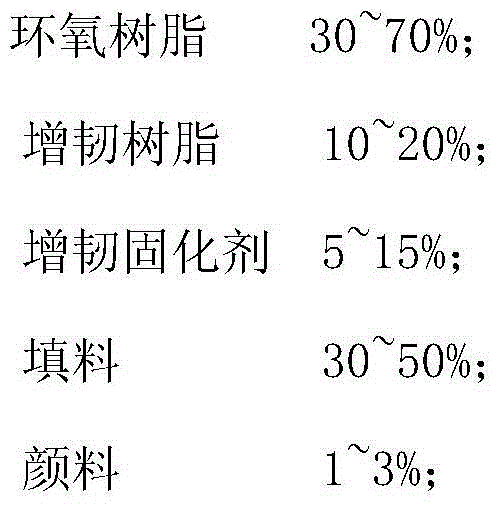

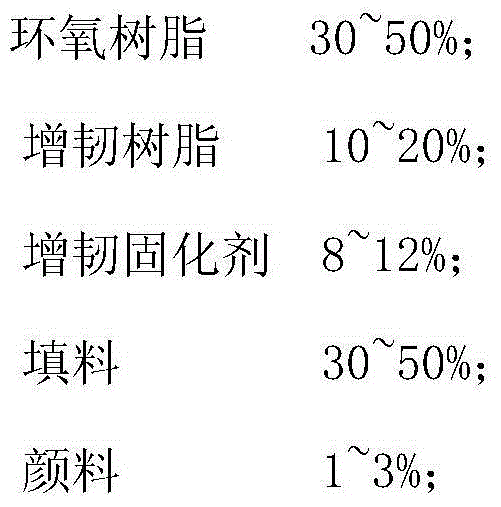

Method used

Image

Examples

Embodiment 1

[0019] Weigh 145Kg of epoxy resin E44145Kg, toughening resin blocking polyisocyanate (Shanghai (Guangzhou) Haoyi Chemical Technology Co., Ltd.) 15Kg, toughening and curing agent polyether arylamine 5Kg, filler quartz powder 38Kg, and pigment 2Kg.

[0020] Mix the above components uniformly to obtain epoxy cement, coded as P-1.

[0021] When in use, apply the epoxy cement to the parts to be repaired on the ship at room temperature, and test the relevant performance after 1 hour.

Embodiment 2

[0023] Weigh 155Kg of epoxy resin E44, toughening resin blocking polyisocyanate (Shanghai (Guangzhou) Haoyi Chemical Technology Co., Ltd.) 18Kg, toughening and curing agent polyether arylamine 6Kg, filler quartz powder 28Kg, and pigment 3Kg.

[0024] Mix the above components uniformly to obtain epoxy cement, coded as P-2.

[0025] When in use, apply the epoxy cement to the parts to be repaired on the ship at room temperature, and test the relevant performance after 1 hour.

Embodiment 3

[0027] Weigh 155Kg of epoxy resin E44, toughening resin blocking polyisocyanate (Shanghai (Guangzhou) Haoyi Chemical Technology Co., Ltd.) 18Kg, toughening and curing agent polyether arylamine 6Kg, filler quartz powder 28Kg, and pigment 3Kg.

[0028] Mix the above components uniformly to obtain epoxy cement, coded as P-3.

[0029] When in use, apply the epoxy cement to the parts to be repaired on the ship at room temperature, and test the relevant performance after 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com