A method for producing glycyrrhetinic acid by microbial transformation and its culture medium

A technology for transforming culture medium and microbial transformation, which is applied in the field of microbial transformation and production of glycyrrhetic acid, the method and the culture medium thereof, can solve problems such as low transformation rate, and achieve the effects of low cost, simple culture process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

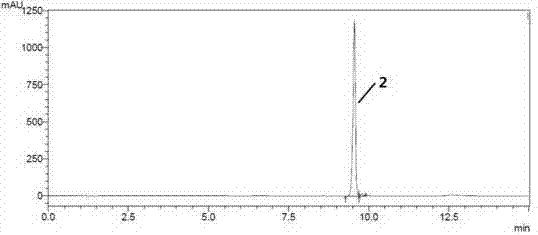

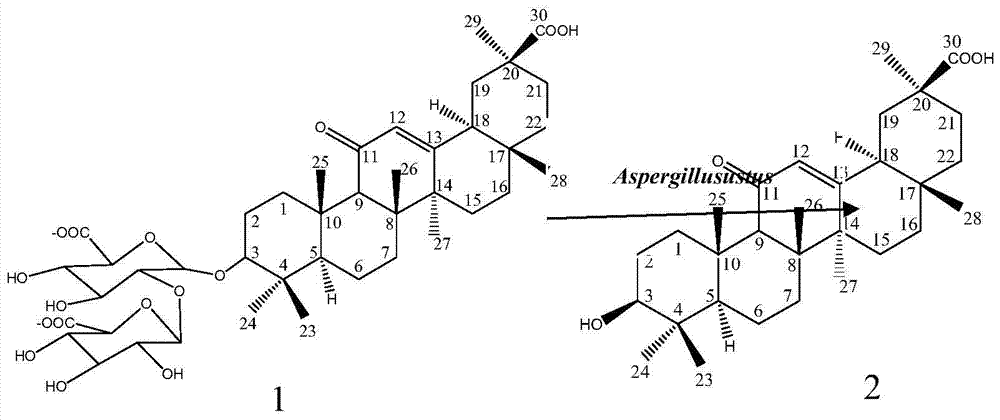

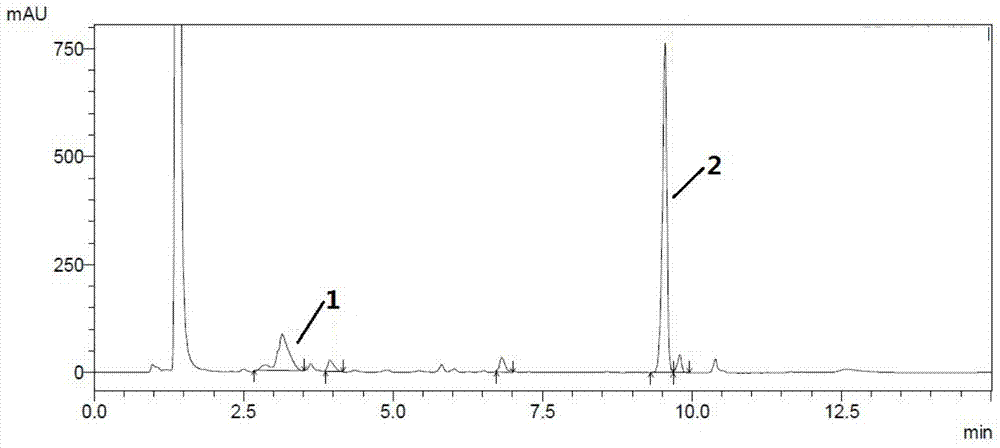

Embodiment 1

[0058] Slant culture: inoculate the strain on the slant medium, and culture at 28°C for 3-7 days.

[0059] Seed culture: use the obtained slant culture to inoculate into the seed medium, shake and culture at 28° C. and 240 rpm for 48 hours to obtain the seed liquid. This seed solution was used in Examples 1-27.

[0060] Wherein, the seed medium is: PDA liquid medium.

[0061] Seed solution is inoculated in the Erlenmeyer flask containing transformation medium with the inoculum size of 10% (v / v), the composition of transformation medium: glycyrrhizic acid 5 grams / liter, MgSO 4 ·7H 2 O0.5 g / L, NaNO 3 5 g / L, FeSO 4 ·7H 2 O0.01 g / L, KH 2 PO 4 1 g / L, pH 5.0. Automatically control the fermentation temperature at 25°C and shake at 200 rpm for 144 hours, and the molar production rate of glycyrrhetinic acid is 82.8%.

Embodiment 2

[0063] Seed solution is inoculated in the Erlenmeyer flask containing transformation medium with the inoculum size of 10% (v / v), the composition of transformation medium: glycyrrhizic acid 5 grams / liter, MgSO 4 ·7H 2 O0.5 g / L, NaNO 3 5 g / L, FeSO 4 ·7H 2 O0.01 g / L, KH 2 PO 4 1 g / L, pH 5.0. Automatically control the fermentation temperature at 30°C and shake at 200 rpm for 144 hours, and the molar production rate of glycyrrhetinic acid is 96.5%.

Embodiment 3

[0065] Seed solution is inoculated in the Erlenmeyer flask containing transformation medium with the inoculum size of 10% (v / v), the composition of transformation medium: glycyrrhizic acid 5 grams / liter, MgSO 4 ·7H 2 O0.5 g / L, NaNO 3 5 g / L, FeSO 4 ·7H 2 O0.01 g / L, KH 2 PO 4 1 g / L, pH 5.0. The fermentation temperature was automatically controlled at 37°C, and the shaking culture at 200rpm was carried out for 144h, and the molar production rate of glycyrrhetinic acid was 69.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com