Double-driving variable speed gate hoist

A hoist and double-drive technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of reducing maintenance costs and not being able to open and close large-capacity down-pressure gates, and achieves increased load-bearing capacity, compact structure, and even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

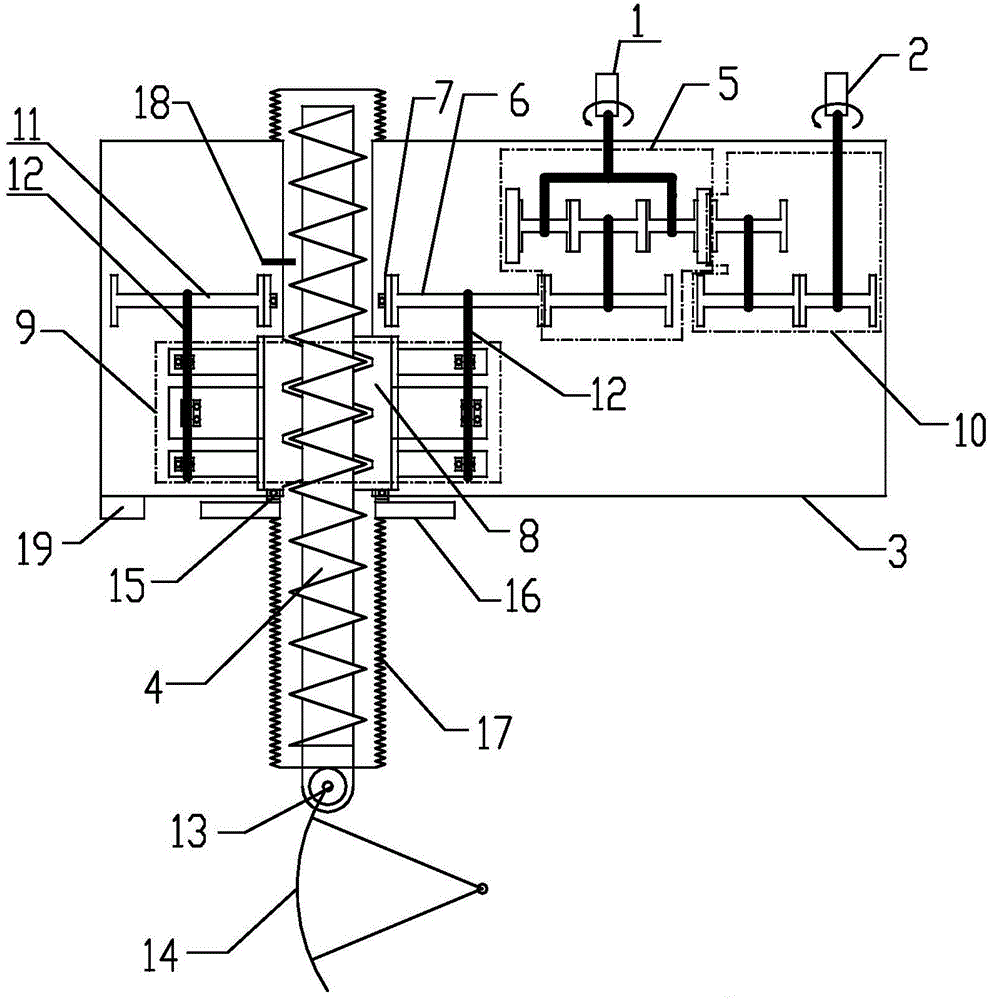

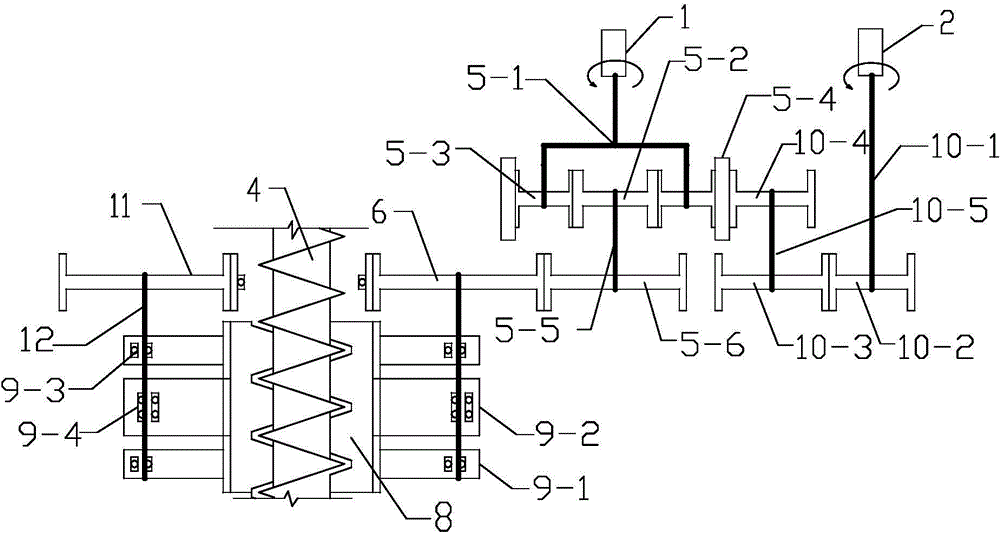

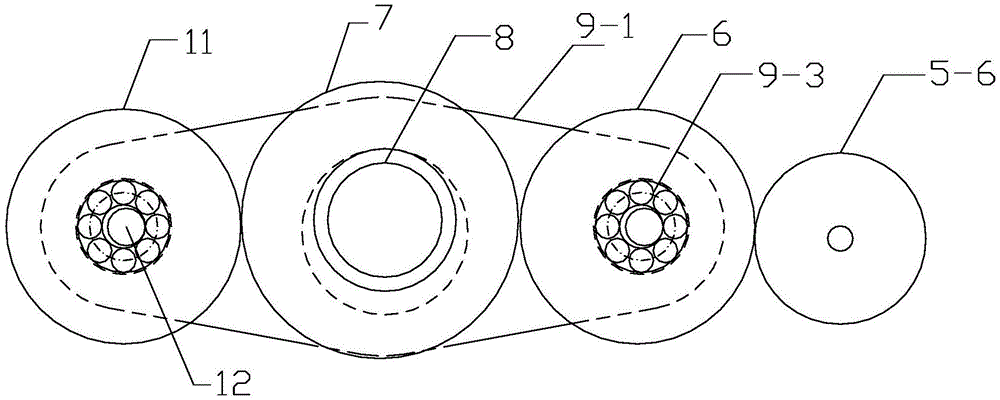

[0034] The present invention will be further described below in conjunction with the accompanying drawings. figure 1 Described a kind of dual-drive variable-speed gate hoist includes high-speed motor 1, low-speed motor 2, transmission box 3, load-bearing nut 8 and screw 4, and described high-speed motor 1 and low-speed motor 2 can be servo motors It can also be a conventional motor. When the high-speed motor and the low-speed motor are servo motors, the servo motor has the function of controlling and monitoring the height of the screw. When the high-speed motor and the low-speed motor are conventional motors, an additional height indicator is required. device 18, and a stroke scale value is correspondingly provided on the middle side of the screw rod, the height indicator 18 can be fixed on the upper part of the transmission box, and its indicating end points to a stroke scale value, and the stroke signal can be transmitted to the controller of the motor for Monitor the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com