Highland backhole loader

A backhoe loader and plateau technology, which is applied in the field of backhoe loaders and new backhoe loaders, to achieve the effects of reasonable design of the whole machine, reduction of fatigue strength, and improvement of body comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

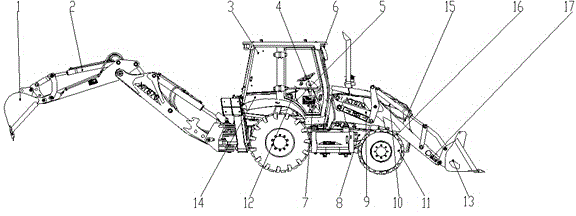

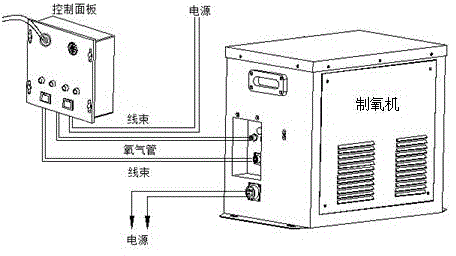

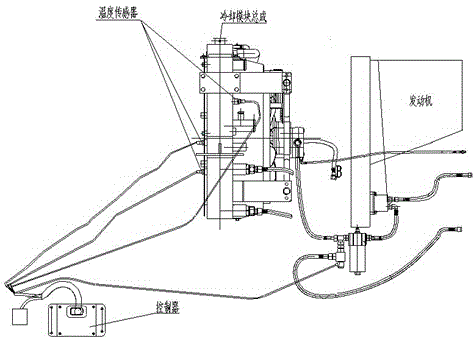

[0022] Such as figure 1 As shown, the plateau type backhoe loader of the present invention takes the vehicle frame 8 as the main body, and includes a loading working device 13, an excavating working device 1, a cab assembly 3, a power system 9, a transmission system 11, a working hydraulic system 2, and a parking brake. System 5 and service brake system 7, steering hydraulic system 4, air conditioning system 12, electrical system 6, hood cover 10, life support system 14, adjustable independent cooling system 15, low temperature heating system 16.

[0023] Among them: the loading working device 13 is installed on the front end of the vehicle frame 8 through the pin shaft; the excavating working device 1 is installed on the rear end of the vehicle frame 8 through the pin shaft; upper middle.

[0024] The power system 9 is fixed on the front frame 8 of the cab assembly 3 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com