Construction method of roof waterproofing

A construction method and roofing technology, applied in the direction of roof covering, building roof, etc., can solve the problems of shortening the service life of roofing waterproof membranes, immediately destroying the sealing body, and difficulty in roof maintenance, so as to reduce construction costs and ensure construction Quality, effect of simplified construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

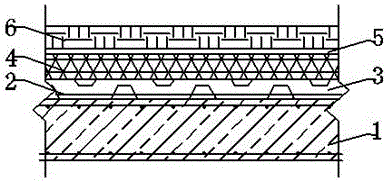

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] In the figure, the roof waterproof construction method of the present invention comprises the following construction steps:

[0020] Step 1. The micro-expansion concrete 1 is poured on the top of the roof. The micro-expansion concrete 1 is firstly vibrated during the pouring process, and the upper surface is leveled. Compacting and calendering to achieve internal solidity and external light;

[0021] Step 2 After the micro-expansive concrete 1 is poured, the roof is cleaned first. After the cleaning is completed, a layer of curing film 2 is covered on the roof. After the micro-expansive concrete 1 is formed, the curing film 2 is immediately covered and cured to prevent the moisture in the concrete from losing too quickly. And cause the generation of crackle phenomenon, then on the upper surface of curing film 2, concrete slope layer 3 is set, and then insulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com