Fuel delivery method for internal combustion engine using gas-liquid two-phase natural gas as fuel

A natural gas and internal combustion engine technology, applied in the field of internal combustion engine combustion system construction, can solve the problems of reducing emissions, disadvantages, and high heat load of combustion chamber parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

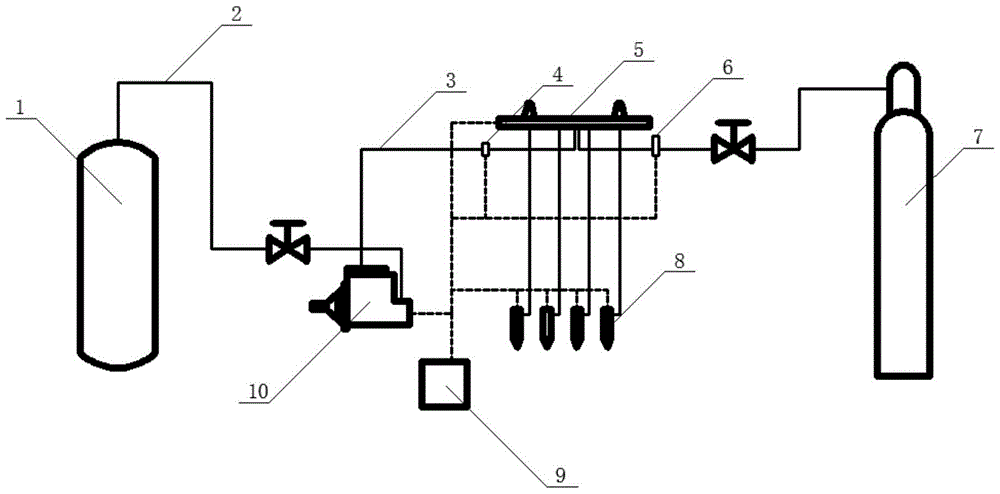

[0047] The technical content of the present invention will be further described below in conjunction with the accompanying drawings.

[0048] Such as figure 1 As shown, the gas-liquid two-phase natural gas internal combustion engine combustion system of the embodiment of the present invention is composed of: the fuel entering the adiabatic common rail 5 has two paths: a liquid path and a gas path; The pressure pump 10 is transported to the adiabatic common rail 5; the gas route enters the adiabatic common rail 5 through the gaseous compressed natural gas cylinder 7 through the corresponding pipe valve;

[0049] 2) The fuel mixed by the adiabatic common rail 5 is delivered to the cylinder from the outlet of the adiabatic common rail 5 through the electronically controlled injector 8;

[0050] 3) The liquid circuit and the gas circuit are provided with corresponding pipe valves for connection, and corresponding pressure sensors are provided in the gas circuit; the internal com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com