Swing reaction device for evaluating performance of hydrate inhibitors

A hydrate inhibitor and reaction device technology, which is applied to measuring devices, material analysis through optical means, instruments, etc., can solve the problems of high gas consumption, inability to be widely used, and difficulty in determining the time of hydrate blockage, etc., to avoid effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

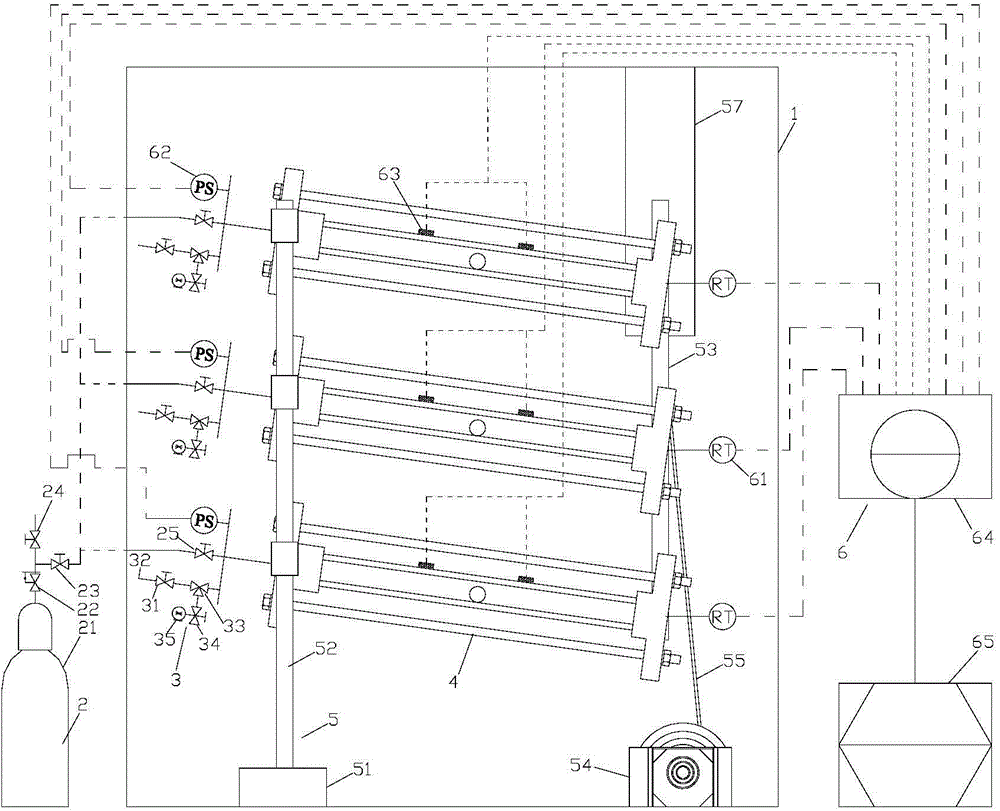

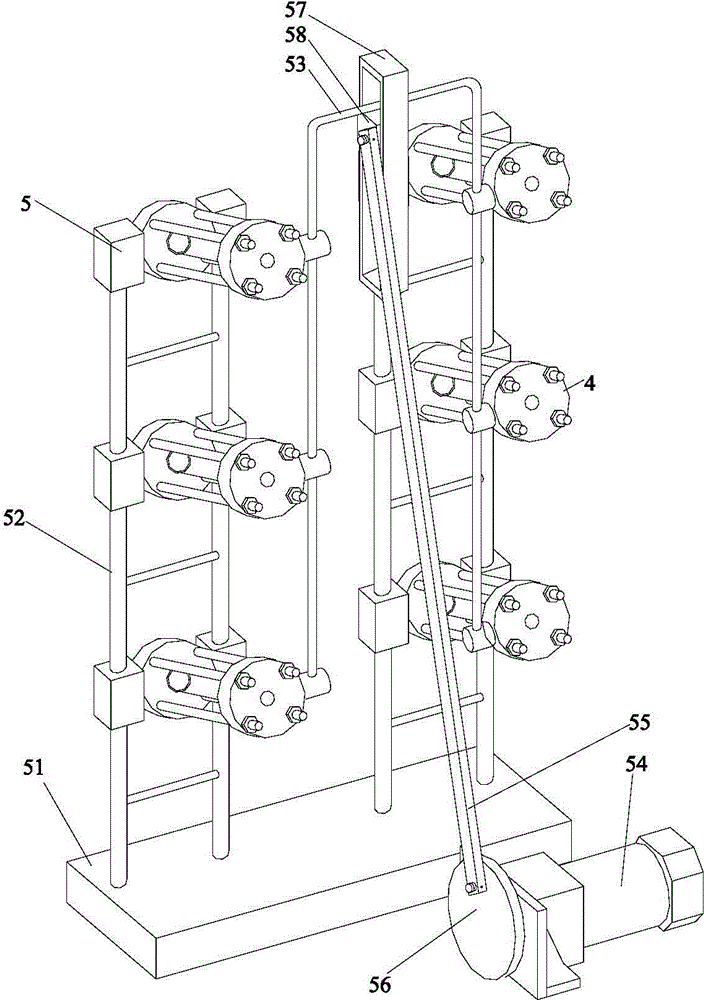

[0031] Such as Figure 1 to Figure 3 As shown, a swing reaction device for evaluating the performance of hydrate inhibitors includes a constant temperature box 1, an air intake system 2, a liquid intake system 3, six high-pressure reactors 4 installed in the constant temperature box 1, a swing system 5, and It includes a data acquisition system 6 and a high-definition camera for photographing the hydrate formation in the high-pressure reactor 4. The six high-pressure reactors 4 are respectively connected to the intake system 2 and the liquid intake system 3. The data acquisition system 6 is used to obtain high-pressure The temperature, pressure, and displacement signals of the reactor 4 and the video data in the high-pressure reactor 4, the swing system 5 fixes the high-pressure reactor 4 and makes it swing periodically.

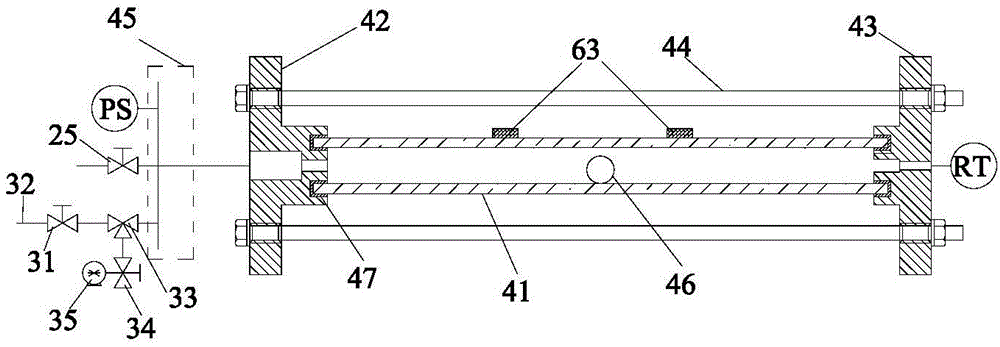

[0032] Such as figure 2 As shown, the autoclave 4 includes a transparent tube 41, a fixed end still cover 42 and a swing end still cover 43 respectively a...

Embodiment 2

[0042] The concrete operation steps of above-mentioned embodiment are as follows:

[0043] (1) For each autoclave 4, close the autoclave inlet valve 25 and liquid inlet valve 31, open the three-way valve 33 and valve 34, turn on the vacuum pump 35 to vacuumize for about 1 minute, and close the valve 34 after vacuuming;

[0044] (2) Group and label each autoclave 4 into 2 groups, the first row is the first group, labeled 1-1, 1-2, 1-3, and the second row is the second group, labeled 2 -1, 2-2, 2-3, respectively place the prepared 17ml solution containing 1wt% PVP K90 in the liquid inlet 32 of 1-1, 1-2, 1-3, open the liquid inlet valve 31, containing The solution of 1wt%PVP K90 is sucked into the transparent tube 41, and the liquid inlet valve 31 is closed; the prepared 17ml solution containing 1wt%HY10 is put into the liquid inlets 32 of 2-1, 2-2, and 2-3, and the inlet valves are opened. Liquid valve 31, the solution containing 1wt% HY10 is sucked into the transparent tube ...

Embodiment 3

[0057] The difference between this example and Example 2 is to compare the inhibitory effects of anti-aggregation agents KL-1 and Span85, and use Span85 as a reference to determine whether KL-1 is an anti-aggregation agent with good anti-aggregation performance. Under the experimental condition identical with embodiment 2, suck 17ml to contain 1.5wt% KL-1 and 17ml to contain 1.5wt%Span85 solution in each still of two groups of autoclave respectively, after charging the mixed gas of 8.7MPa, wait After the temperature and pressure signals are stable, set the temperature of the temperature-controlled freezer to 2.0°C. Judging from the temperature and pressure signals and high-definition camera, the induction time of adding 1.5wt% KL-1 solution is 108min, the blocking time is 313min, and the stopping time is 437min; the induction time of adding 1.5wt% Span85 is 105min, and the blocking time is 254min, and the stopping time was 357min, the induction time of the two is not much diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com