Prediction control method for modularized multi-level inverter

A modular multi-level, predictive control technology, applied to electrical components, output power conversion devices, AC power input conversion to DC power output, etc., can solve problems such as poor dynamic and static performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] (1) Topological analysis:

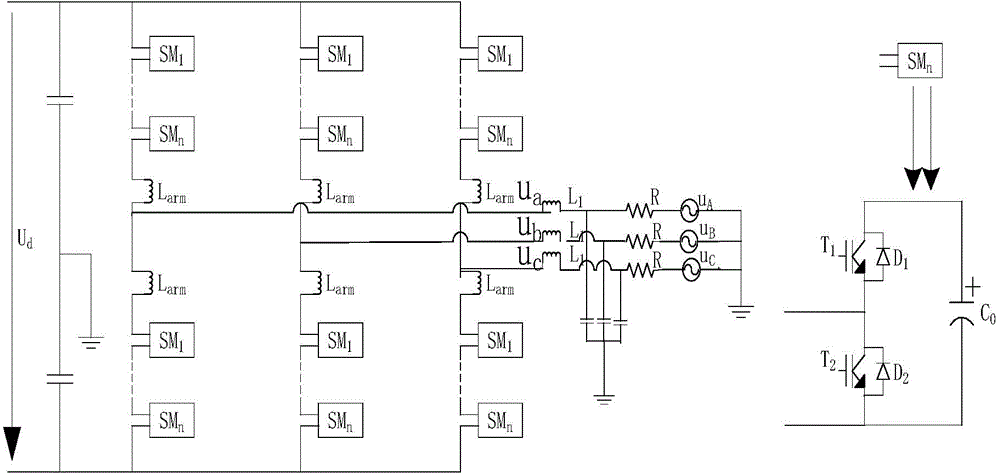

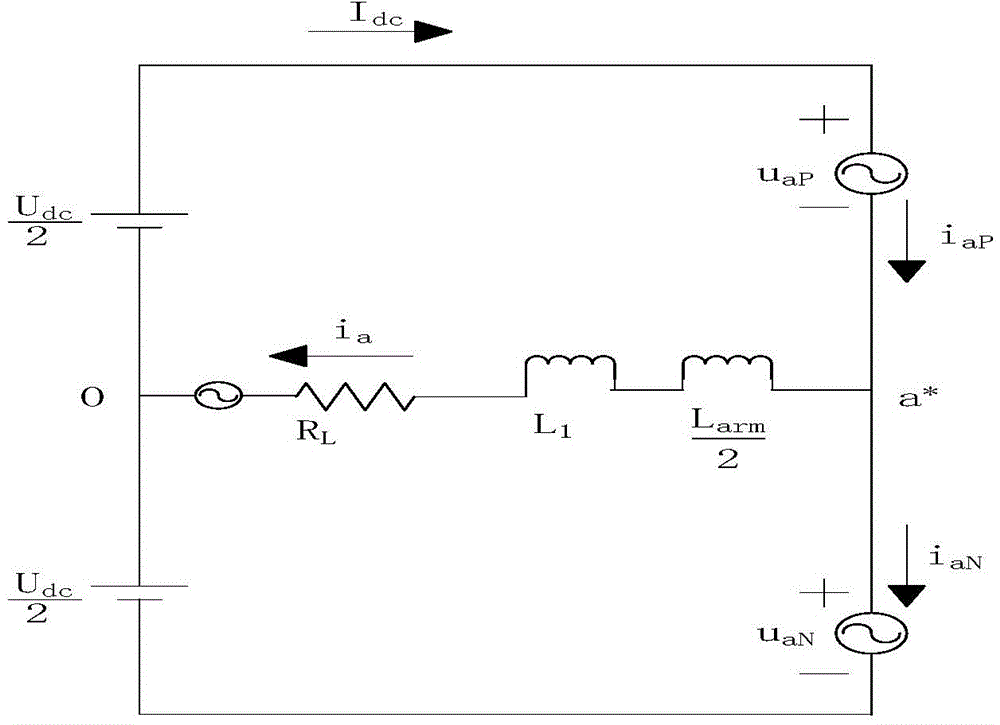

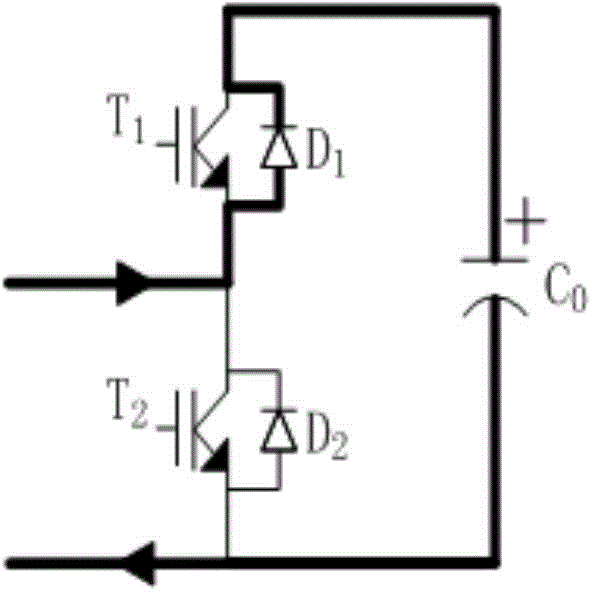

[0080] The topology and internal model of the modular multilevel converter are shown in the attached figure 1 , the present invention is suitable for modular multilevel converters, and has been verified on the system simulation of half-bridge module quantity n=4 by figure 1 It can be seen that (where i=a, b, c, I=A, B, C) Since there is an inductance L in the upper and lower bridge arms of each phase in the three phases arm So its single-phase equivalent circuit is as figure 2 Shown:

[0081] Therefore, the above formula can be transformed into: By transforming the three-phase voltage and current into the αβ coordinate system through 3-2, we can get u α * = ( L 1 + L arm 2 ) ...

Embodiment 2

[0114] When n=6, there are 2n=12 sub-modules in each phase, since the number of sub-modules in each phase is always n=6, so there are seven combinations of the number of sub-modules in the upper and lower bridge arms of each phase: 6, 0; 5, 1; 4, 2; 3, 3; 2, 4; 1, 5; 0, 6; Let the capacitor voltage in the module be U c , then the phase output voltages in these seven cases are: 6U c , 4U c , 2U c , 0, -2U c 、-4U c 、-6U c ; By controlling these seven combinations, the output waveform can be sine wave. Let the DC bus voltage be U dc , so the MMC three-phase inverter has five output voltages for each phase: 0, And the three phases can output 7*7*7=343 voltage states in total.

[0115] Each of the upper and lower bridge arms has 6 sub-modules, and the capacitor voltage and current direction of each sub-module at a certain time. Assuming that it is calculated from the above control strategy, the upper bridge arm needs to invest in 2 sub-modules, and the lower bridge ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com