A degradable environmental protection mask

A mask and environmental protection technology, applied in clothing, protective clothing, applications, etc., can solve the problems of brittleness, poor skin affinity, and high plastic strength, achieving great application prospects and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

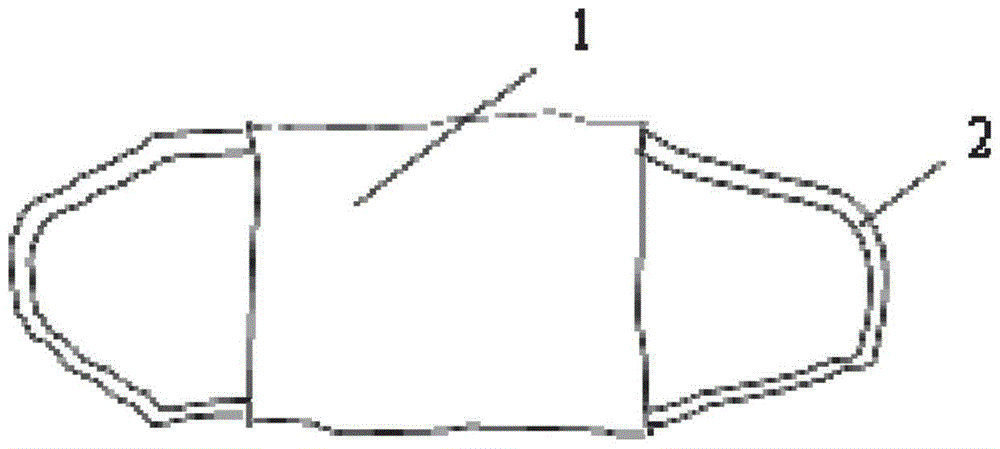

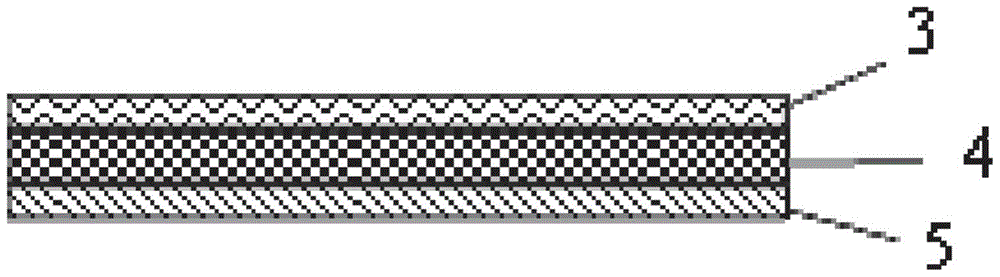

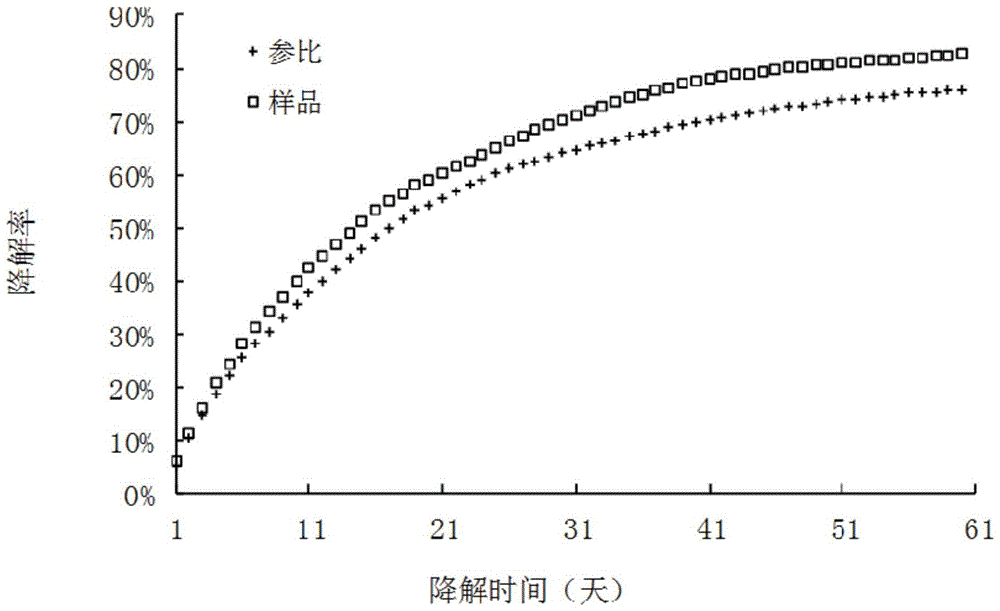

Embodiment 1

[0033] A fully degradable environmental protection mask of the present invention comprises a mask body and ear straps arranged on both sides of the mask body. The mask body includes an outer layer of PBS non-woven fabric, a bamboo fiber filter layer, and an inner layer of PBS non-woven fabric from outside to inside. cloth. The PBS non-woven fabric used in the inner and outer layers and ear bands is made of PBS, starch, antibacterial and anti-mite agent, nucleating agent and dispersant. The parts by weight of each raw material are 79 parts of PBS, 10 parts of cornstarch, 7 parts of zinc antibacterial agent, 2 parts of bis(3,4-dimethyldibenzylidene) sorbitol, and 2 parts of ethylene bisstearamide. The surface density of the prepared PBS non-woven fabric is 25g / m 2 . The bamboo fiber used is bamboo fiber needle-punched cotton with a surface density of 160g / m 2 . The overall schematic diagram of the made environmental protection mask is as attached figure 1 As shown, the cros...

Embodiment 2

[0035] A fully degradable environmental protection mask of the present invention comprises a mask body and ear straps arranged on both sides of the mask body. The mask body includes an outer layer of PBS non-woven fabric, a bamboo fiber filter layer, and an inner layer of PBS non-woven fabric from outside to inside. cloth. The PBS non-woven fabric used in the inner and outer layers and ear bands is made of PBS, starch, antibacterial and anti-mite agent, nucleating agent and dispersant. The parts by weight of each raw material are 68 parts of PBS, 20 parts of potato starch, 7 parts of chitosan, 2 parts of 2,2 methylene-bis(4,6-di-n-butylphenol) sodium phosphate, 2 parts of sodium pyrophosphate, the surface density of the prepared PBS non-woven fabric is 28g / m 2 . The bamboo fiber used is bamboo fiber needle-punched cotton with a surface density of 150g / m 2 .

Embodiment 3

[0037] A fully degradable environmental protection mask of the present invention comprises a mask body and ear straps arranged on both sides of the mask body. The mask body includes an outer layer of PBS non-woven fabric, a bamboo fiber filter layer, and an inner layer of PBS non-woven fabric from outside to inside. cloth. The PBS non-woven fabric used in the inner and outer layers and ear bands is made of PBS, starch, antibacterial and anti-mite agent, nucleating agent and dispersant. The parts by weight of each raw material are 56 parts of PBS, 30 parts of tapioca starch, 9 parts of the mixture of potassium sorbate and silver antibacterial agent, 2 parts of dibenzylidene sorbitol, 3 parts of monoglyceride stearate, the surface density of the prepared PBS non-woven fabric is 32g / m 2 . The bamboo fiber used is bamboo fiber needle-punched cotton with a surface density of 150g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| izod impact strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com