Production method of novel ceramic tile

A production method and ceramic tile technology, applied in the field of building materials, can solve the problems of no function, no bactericidal function, environmental pollution, etc., and achieve the effect of reducing the use of daily chemicals, cleaning toxins in the body, and improving the quality of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

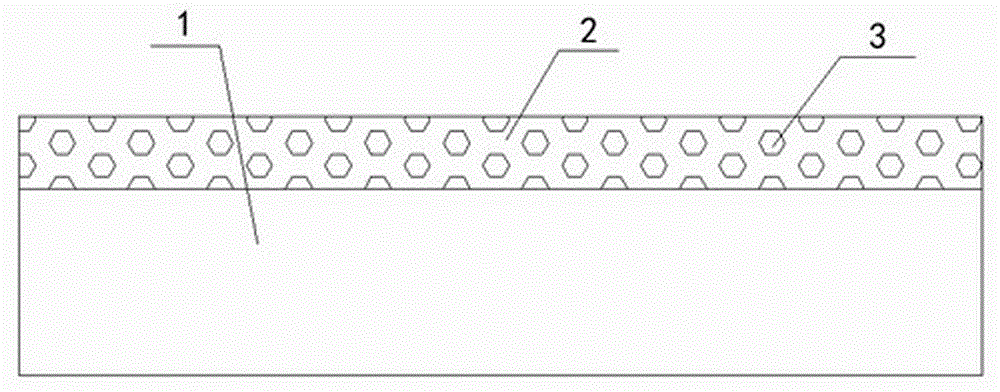

Image

Examples

Embodiment 1

[0034] Glazed brick glaze formula: industrial zinc oxide: 3-8; industrial barium carbonate: 15-30; potassium feldspar: 30-50; zirconium silicate: 20-40; alumina powder: 3-10; white talc : 5-15; kaolin: 5-15; nano zinc oxide: 2-10. After adding to the ball mill tank for mixing, add 0.6-1.5 times the same proportion of water to fully ball mill.

[0035] After 3 hours, add the average particle size of the product: 24nm nano-zinc oxide (nano-zinc oxide and titanium dioxide are both semiconductor materials, which have a catalytic function; the difference is that titanium dioxide is dependent on ultraviolet light.) Equal ball mill to glaze grinding solubility It is about 350g / 200cc, and the fineness is 200 mesh nano antibacterial glaze. (adding formula: nano zinc oxide * glaze specific gravity * percentage / solid content of zinc oxide).

[0036] According to the actual trial, the completed glaze can be coated on the surface of the green tile or plain embryo, and the glaze on the ...

Embodiment 2

[0038] Add nano-zinc oxide to the embryo body of the brick embryo at a solid content of 6%, and adjust the formula ratio of the brick according to the temperature of the brick.

[0039] The formula of raw materials fired into the ceramic body: feldspar: 30-50; porcelain stone: 20-40; quartz: 3-10; clay: 20-30; talc: 1-5;

[0040] ① Kaolinite: such as ball clay, precipitated kaolin, etc.; ② Illite: such as porcelain stone, porcelain sand and its weathered products; ③ Montmorillonite: such as bentonite; ④ Pyrophyllite: some information Pyrophyllite is classified into hard clay, especially sericite type, dickite type and kaolinite type pyrophyllite have certain plasticity after grinding.

[0041] Commonly used fluxes and mineralizers are: ①Potassium-sodium system: potassium feldspar, albite, potassium-sodium feldspar, porcelain stone, porcelain sand, etc.; ②Calcium-magnesium system: diopside, tremolite, magnesia clay (or called talc clay), talc, etc.; ③composite system: nano zin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com